Abstract

Technology has advanced massively over recent years and this has impacted the jewellery industry in many ways; including the way jewellery is designed and the process of making the jewellery. There has been new technological advances such as 3D printing, this is a process in which a 3D model is created from an electronic idea using computer aided design programmes. 3D printing has dramatically changed the way jewellery can be designed and manufactured, without having to use any traditional bench skills to create the jewellery pieces. Will recent technology advances make traditional jewellery making and designing techniques redundant? Will any kind of bench skills used to create jewellery become unnecessary in the near future? This study aims to explore the use of traditional jewellery making methods, the use of technology in jewellery manufacture and the advances over recent years in the technology used to create jewellery. To achieve a balanced study on this subject, I will research sources available such as; books, websites and journals. I will be discussing the impact of technological advances to see the advantages and disadvantages this may have on jewellery manufacture.

Introduction

The topic under discussion is the impact of technological advances on jewellery manufacture, and how jewellery is being created differently with new techniques and processes. This study will explore the use of traditional jewellery making methods and how techniques have evolved over time, how technological advances such as 3D printing will affect the future of jewellery production in the commercial jewellery industry.

The nostalgic image of a craftsman forming jewellery at a work bench with tools, remains more or less the same since ancient times, but today, as well as traditional methods, jewellers now have access to new technologies.

Will there still be a requirement to learn bench skills to create jewellery or will the jeweller’s skills become technology based?

Chapter 1- Past Market

History of jewellery making

The first concrete evidence of body ornamentation was found in drawings of cave dwellers, believed to be at least 20,000 years old. Inedible animal body parts such as teeth, claws, tusks and vertebrae were strung or pierced and worn as ornaments.

In the Stone Age they used a technique called Boring. Pebbles could be perforated and a cord passed through the hole, transforming it into a bead. Boring was performed with palm rotated hand-drills on stone, flint and chert (fine grained quartz). Surface stone polishing was another technological development that occurred around the same time.

With such advances jewellery could be created from durable substances, the stone bead was the first man made mineral ornament that was made by altering the form of raw materials. Much later polished stones would be mounted and set into metal to create decorative jewellery pieces.

Technological advances over the past century have had a huge beneficial impact on jewellers’ craft. The creation of the microscope, binoculars and devices for grading diamonds have made a huge impact towards the improvement of quality jewellery making. More advances created the ability to synthetically create gemstones in order to replicate the more expensive stones, making jewellery more affordable.

Diamond cutting techniques advanced in 1919 when Marcel Tolkowsky established a mathematical deduction to achieve the best diamond cut. Gemological instruments were developed which included refractometers, dichroscopes, polariscopes, specialised microscopes and Proportion scope. These instruments were to become standard equipment in jewellery stores along with the revolutionary diamond grading system distinguishing the quality (and rarity) of these gems for the jeweller and customer.

Wax casting, the traditional method of crafting a metal object based upon a wax model, dates back to the time of the ancient civilisations and is still in common use to this day, as is the Archimedes drill, a hand drilling device invented in the 2nd century BC by the man himself. In the twenty first century jewellers now have the addition of a vast array of modern new tools and instruments to help them.

Any tradesman, including the jeweller, develops and enhances their skill by repeatedly practicing, learning and gaining complete and effective control over their tools. Coupled with dedication and practice the craftsperson becomes a true master of their skill, creating pieces of art and of beauty by simply patiently applying their skills to stones, gemstones, precious metals and materials.

Tools of the Trade

Tools of the Trade

Figure 1 – 158mm Double Combination Rolling Mill – https://www.riogrande.com/product/158mm-double-combination-rolling-mill/113549

The rolling mill is an important and useful machine that is used to reduce the thickness of metal in plate or sheet form, while increasing both in length and width, or to reduce the dimension of round or square wire. The rolling mills used by jewellers are specifically designed for small-scale work. Mills used by jewellers range in roll diameter and length.

The thinner the desired gauge of metal sheet, the more rigid the mill must be and the greater the power and torque to be applied.

Defects can occur if the metal being rolled picks up foreign matter or if the roll becomes scarred or damaged or if an irregular thickness is rolled.

Figure 2 -Tapering Wire Using a Rolling Mill – https://www.youtube.com/watch?v=ML2en0Suhvw

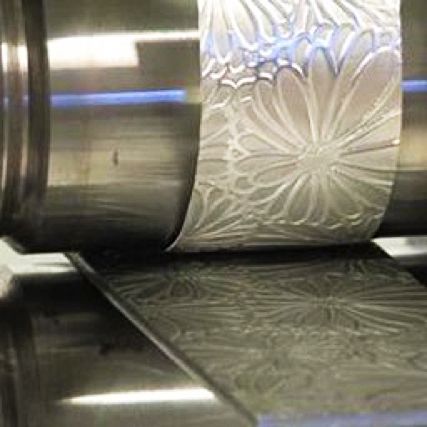

An impression can be made on sheet metal from any material such as metal screening, wire, clippings, fabrics, lace, leaves and feathers by placing them between two clean sheets of annealed metal and then passing them through the rolls of a rolling mill. The pressure of the rolls forces these materials into the metal so that they create a clear imprint on both sheets. The textured material can also be rearranged on the sheet and a second, overlapping impression can be made on the first. In industry rolls are sometimes shot blasted to texture their surface so that the metal rolled through them also has this texture.

An impression can be made on sheet metal from any material such as metal screening, wire, clippings, fabrics, lace, leaves and feathers by placing them between two clean sheets of annealed metal and then passing them through the rolls of a rolling mill. The pressure of the rolls forces these materials into the metal so that they create a clear imprint on both sheets. The textured material can also be rearranged on the sheet and a second, overlapping impression can be made on the first. In industry rolls are sometimes shot blasted to texture their surface so that the metal rolled through them also has this texture.

Figure 3 – creating texture using a rolling mill – https://www.pinterest.co.uk/pin/220606081721888844/?lp=true

One of the most basic sheet metal hand cutting tools is the shears, which have been in use since the Iron Age. The mechanical principle of shears is of a double lever that pivots around the fulcrum, the central bolt that holds them together. When cutting sheet metal, the sheet is inserted between the jaws of the blades. Bench shears are manually operated power tools used for cutting heavier sheet metal and rods. This tool is sometimes called bench alligator shears, and must be bolted to the workbench to keep it rigid. Bench shears are available in several sizes, the larger the model the heavier the sheet and rod can be cut with it. Guillotine shears are hand or foot operated power shears similar in principle to the above-mentioned bench shears.

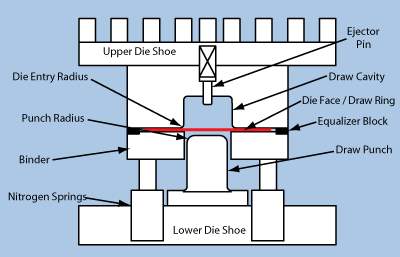

The stamping press is a metalworking machine used mainly to shape and cut sheet metal with a die. The stamping press is similar to the drop hammer machine, using male and female dies to dictate the shape of the final product; it has a similar effect as a hammer and anvil. The press consists of a frame, a bolster plate and a ram and works by forming the metal between two halves of the press tool to match the size and shape of the die.

The stamping press is a metalworking machine used mainly to shape and cut sheet metal with a die. The stamping press is similar to the drop hammer machine, using male and female dies to dictate the shape of the final product; it has a similar effect as a hammer and anvil. The press consists of a frame, a bolster plate and a ram and works by forming the metal between two halves of the press tool to match the size and shape of the die.

Figure 4 – Die Springs- https://www.globalspec.com/learnmore/mechanical_components/springs/die_springs

Engraving is the process or art of engraving a design on a hard surface such as a decorative technique. Engraving on metal came after the use of graphic embellishments on a variety of non-metallic materials such as shell, bone, ivory, gourds, coconut shell, bamboo, wood and stone. Our earliest engraving tools were made of bevelled pointed flint, found in the Upper Palaeolithic culture in Western Europe. Shortly after we entered the age of metals, stone tools were replaced by sharp, pointed tools made of copper or bronze and eventually iron.

Any design made up of lines and points, or that can be small-scale carved is possible to engrave. Such designs can be scriptatory, representational, totally abstract or textural patterns.

Engraving in jewellery work takes place slowly, and is generally small in scale. It is therefore essential to work by a good, shadow-less, natural light or diffused electric light.

The most useful holding device used by engravers is the professional engraver’s block or ball, which is a form of vice, and a precision made tool. It consists of two main parts, at the top is the crown which is holding a vertical split that has closed diameter of 2-5 inches or more. The general name for an engraving tool is a burin, and is also known as a graver. Gravers are also called scorpers, especially when used for purposes other engraving line patterns. The burin’s shaft is made of a rod made from a good grade of tool steel which when hardened and annealed is capable of engraving metals normally used by the jeweller. It can be rectangular, square, diamond-shaped, triangular, oval or round. Each of the forms gives a differently shaped cutting tip, which will result in the work piece having different characteristics.

Figure 5- hand engraving – http://www.lindensjewelry.com/engraving

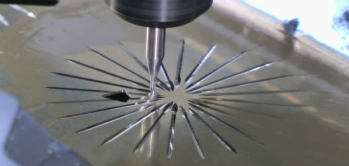

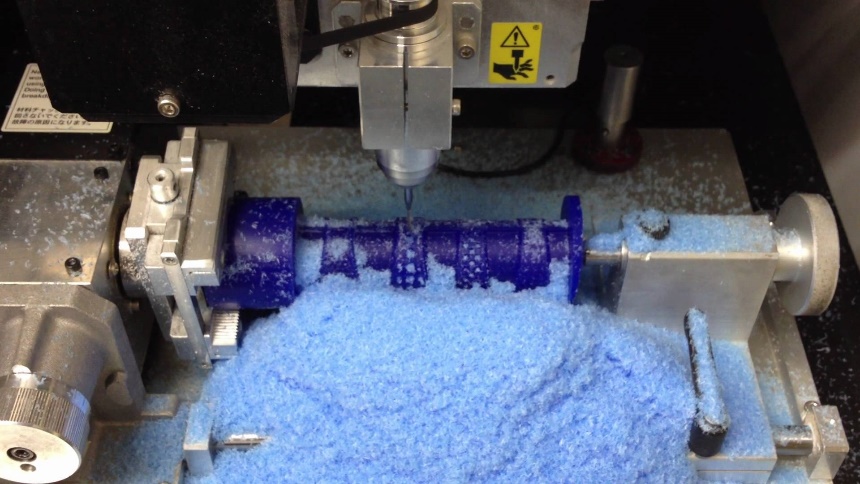

Milling is a traditional technique that is a basic process in the crafting of handmade jewellery that is used to create a variety of features. Milling is a machining process of removing unwanted metal using high-speed multiple toothed rotary steel cutter, removing metal from the surface of a workpiece by making multiple small cuts to create the desired shape. The process is also known as frazing when it involves the mechanical reaming or enlarging of a hole. Milling is used to add precision features to jewellery and can also be used for carving of wax to create jewellery.

Figure 6 –Jewellery Milling Machine – https://www.youtube.com/watch?v=jDuHDUWsdZ4

Figure 7 – Wax Jewellery Milling – https://www.youtube.com/watch?v=ZJJyvl55QHI

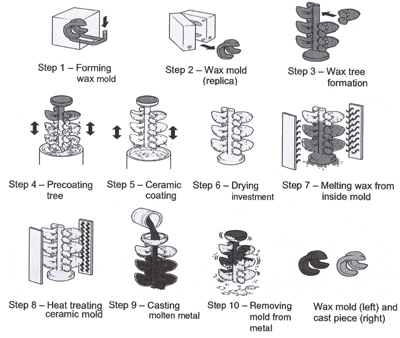

Lost-wax casting is an ancient process that casts a metal sculpture from wax. Traditionally conventional hand carving tools such as files and carving tools were used by designers. Heated tools are now available such as the electric wax carver and cordless thread burner that provides quick sculpting and precision carving

Moulds are created using jeweller’s wax, which is a hard wax, unlike beeswax. Once the wax moulds have been carved the mould is then cast in an oven where molten metal was poured into the wax mould. Once cooled the wax mould is broken apart leaving a rough cast of the piece of jewellery which is then filed and polished by hand.

Wax has the advantage of being inexpensive and is easy to correct if a mistake is made, by adding more wax or using heated tools.

Wax casting is an ideal way to create individual one-off original pieces.

Figure 8 – lost wax casting – http://www.sandipointe.com/im/arts-crafts-sewing/lost-wax-casting-11.jpg

Advantages/Disadvantages

The advantages of handcrafting jewellery are considerable, including the creation of bespoke work of unique character, forming one of a kind pieces for the individual, making it more personal for the customer. Pieces are produced by someone with a passion using traditional methods, evoking the time, effort and expertise. Basic tools are less expensive than a 3D printer. Bench skills will always be required for repair work and finishing pieces such as embellishments and adjustments.

Although there are several advantages there are also some disadvantages of handcrafting; it takes time and dedication to become a skilful expert, there is a greater risk of errors and damage when handcrafting, which can be expensive and lead to loss of valuable resource and time. It is also time consuming to produce handcrafted jewellery. Space is required to develop a practical workshop, which people may need to rent which adds to overheads in manufacture. Consideration of health and safety limitations will require further investment to mitigate effects of chemicals and equipment used, further consideration should be applied to personal injury or strain which may develop from over periods of time or accidental events.

In the modern age, where high standards of health and safety are paramount, technological advancements come into play in an essential if not creative capacity in the workshop. Working with chemicals, metals, man-made materials and machines comes with its hazards.

Some of the most important advancements in relation to Health and Safety in the Workshop/Workplace are:

Chapter 2 – current market

In the workshop

The workshop of a jeweller can be any place in which the activity of jewellery making takes place. According to law a workshop is also defined as a place of manual labour, where no machinery worked by mechanical power is employed (this would classify as a factory). In the western society one person jewellery workshops are common, as jewellery making is generally a solitary craft. For someone starting a workshop for jewellery making activity they will need a few basic areas: the fabrication construction area, heating area, acid operation or pickling area, finishing and polishing area.

The fabrication construction area consists of hand tools, workbench, seat and bench-vice.

A traditional jeweller’s bench is purpose designed to provide the perfect working area. Benches are higher than a normal desk (mid chest level when sitting upright) to ensure the jeweller does not stoop to work. Most benches have a semi-circle cut out to enable the jeweller to sit close to the work. Most benches are equipped with a retractable bench skin to catch scrap metal filings and protect the jeweller from hot or sharp objects. Usually there are small drawers for the storage of tools and small items. Tools and materials should be kept close for immediate access. Basic jewellers tools Benches should be constructed solidly enough to enable a bench vice to be fixed, to be able to absorb the shock when using hammering work tools such as small anvils and mandrels held in the vice jaws.

A traditional jeweller’s bench is purpose designed to provide the perfect working area. Benches are higher than a normal desk (mid chest level when sitting upright) to ensure the jeweller does not stoop to work. Most benches have a semi-circle cut out to enable the jeweller to sit close to the work. Most benches are equipped with a retractable bench skin to catch scrap metal filings and protect the jeweller from hot or sharp objects. Usually there are small drawers for the storage of tools and small items. Tools and materials should be kept close for immediate access. Basic jewellers tools Benches should be constructed solidly enough to enable a bench vice to be fixed, to be able to absorb the shock when using hammering work tools such as small anvils and mandrels held in the vice jaws.

Figure 9 – Jeweller’s Bench – https://www.cooksongold.com/Jewellery-Tools/Jewellers-Bench-Birchwood-prcode-997-120B

Soldering can take place, if necessary, on the same workbench if the surface is protected with a refractory board. It is preferable to have a separate soldering table which should be placed away from natural light so that the colour of the heated metal can be easily seen during soldering.

Heat generating processes such as soldering requires a pickling process to clean the metal. This area should be near to the soldering table and a water supply and adequate ventilation, ideally near an open window or workshop equipped with an exhaust fan.

3D Printing

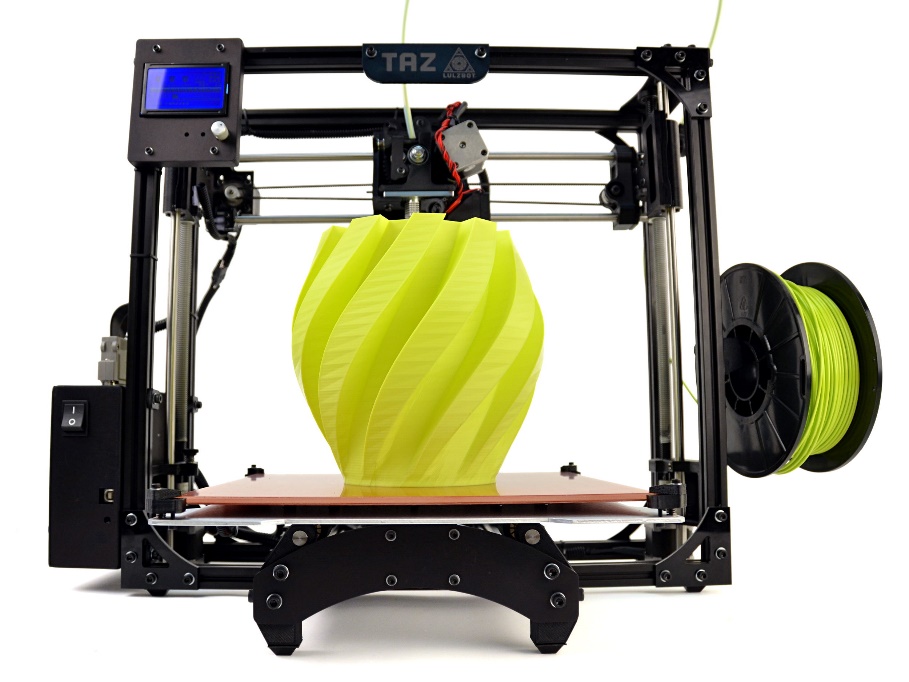

3D printing is a fascinating technology that can be utilised across many different industries especially the manufacturing industry. This is the process of creating a 3D object from a digital file, the technologies used produce component parts layer by layer through the additional use of materials. The technical name for 3D printing is “additive manufacturing”, 3D printing is not a new technology, 3D printers have been used in manufacturing machine shops for decades. In the past few years 3D printing has rapidly been driven forward by advances in computing power, new design software, new materials and the internet. There are several ways to print differing mainly in the way the layers are built to create the final object, some methods use melting or softening materials to produce the layers. Selective layer sintering and fused deposition modelling are the most common technologies using this way of printing. To prepare a digital file for printing, the 3D modelling software “slices” the final model into hundreds or thousands of horizontal layers. Once the sliced file is uploaded into a 3D printer the object can be created layer by layer. The 3D printer reads every slice (2D image) and creates the object by blending each layer with hardly any visible sign of the layers, resulting in the final three dimensional object. I will be exploring the influence of 3D printing on future design practice and what impact the technology will have on society.

3D printing technologies can now be bought online from retailers for as little as £1000, turning the consumers into manufacturers; completely changing manufacturing across supply chains. There are many benefits to 3D printing, one of them being that it is completely tool-less, presenting companies with a wide and ever expanding range of technical, economic and social benefits. Using 3D printing it is possible to reduce the need for fixed assets. Another advantage of 3D printing is it also enables manufacturers to cost effectively produce in very low unit volumes. As well as this the layering nature of 3D printing enables the manufacture of highly complex shapes with very few geometric limitations compared to traditional manufacturing processes. This allows manufacturers to produce parts that would not have been easily made using traditional methods, if at all. The layer-wise manufacturing approach of 3D printing can also reduce the amount of raw materials used during production, helping to save on natural resources.

With the increasing media attention surrounding 3D printing, consumers are facing greater exposure to the technology and the advantages that it provides. One of the most prominent of these advantages is the ability to personalise an object by the consumer. As a digital technology, 3D printing is progressively being used with the internet and other digital data sources, enabling consumers to be able to directly engage in the product design process. This allows for product personalisation like never before. A small yet growing industry has now surfaced to capture this fledgling market of consumer design makers. This could encourage individuals to start creating their own designs and marketing them. Consumer 3D printers are now being sold as ‘plug-and-play’ electrical devices, which can be configured and used by the general public with little training or experience.

With the increasing media attention surrounding 3D printing, consumers are facing greater exposure to the technology and the advantages that it provides. One of the most prominent of these advantages is the ability to personalise an object by the consumer. As a digital technology, 3D printing is progressively being used with the internet and other digital data sources, enabling consumers to be able to directly engage in the product design process. This allows for product personalisation like never before. A small yet growing industry has now surfaced to capture this fledgling market of consumer design makers. This could encourage individuals to start creating their own designs and marketing them. Consumer 3D printers are now being sold as ‘plug-and-play’ electrical devices, which can be configured and used by the general public with little training or experience.

Figure 10 – 3D Printer – https://www.lulzbot.com/store/printers/lulzbot-taz-5#&gid=2&pid=3

The use of 3D printing to manufacture spare parts at home has generated a large amount of interest in recent years. There is appeal for consumers to be able to repair costly domestic appliances without having to be dependent upon manufacturers and distributors to hold stock of spare parts. The advantage of using home-based 3D printing to manufacture spare parts is that it enables consumers to manufacture a one-off product at a very low volume with no cost penalty, unlike with traditional manufacturing methods. This would have a huge impact on society making household appliances easily repairable, there would be much less demand for manufacturers to keep creating and distributing spare parts for household items that could be easily repaired in the home. Although the idea of printing spare parts at home for domestic appliances appears to hold much promise, and to a small extent is already taking place today, it is believed that it will be a substantial amount of time before this becomes a widespread practice.

The earliest items of jewellery created by 3D printers were plastic earrings and pendants. Today industrial 3D printing processes can produce solid forms in various metals including titanium, brass and bronze. The most difficult metal to print using 3D printers is gold as it reflects 90% of the laser beam’s energy, making sintering of gold powder challenging. Gold 3D printing is available from specialist suppliers but is very expensive, costing several hundred thousand pounds to fill a machine with enough gold powder to be economically viable. Desktop 3D printers enable the production of smaller and more detailed pieces, with the ability to customise intricate artwork for individual designers.

As new technologies are created the threat of Intellectual Property rights to established companies is heightened. Commercial manufacturers may be forced to comply with a form of digital rights management (DRM) to see whether it violates someone’s intellectual property. It will be necessary to develop a database protecting Intellectual Property designs that can be linked to the 3D printer’s software. However, this system is unlikely to be enforced for home 3D printers.

A great variety of sizes is available of 3D printers for the production of jewellery depending on the criteria of the business such as the production capacity, the resolution required, whether it is for an individual jeweller, small business or large business. Sizes arrange from desktop printers

Large format 3D printers are available for groups and companies who wish to produce a massive output as it has the capacity to print multiple pieces and print huge objects. For individuals who want to enjoy 3D printing at home or in a small workshop and only aim to produce small objects, small 3D printers are adequate.

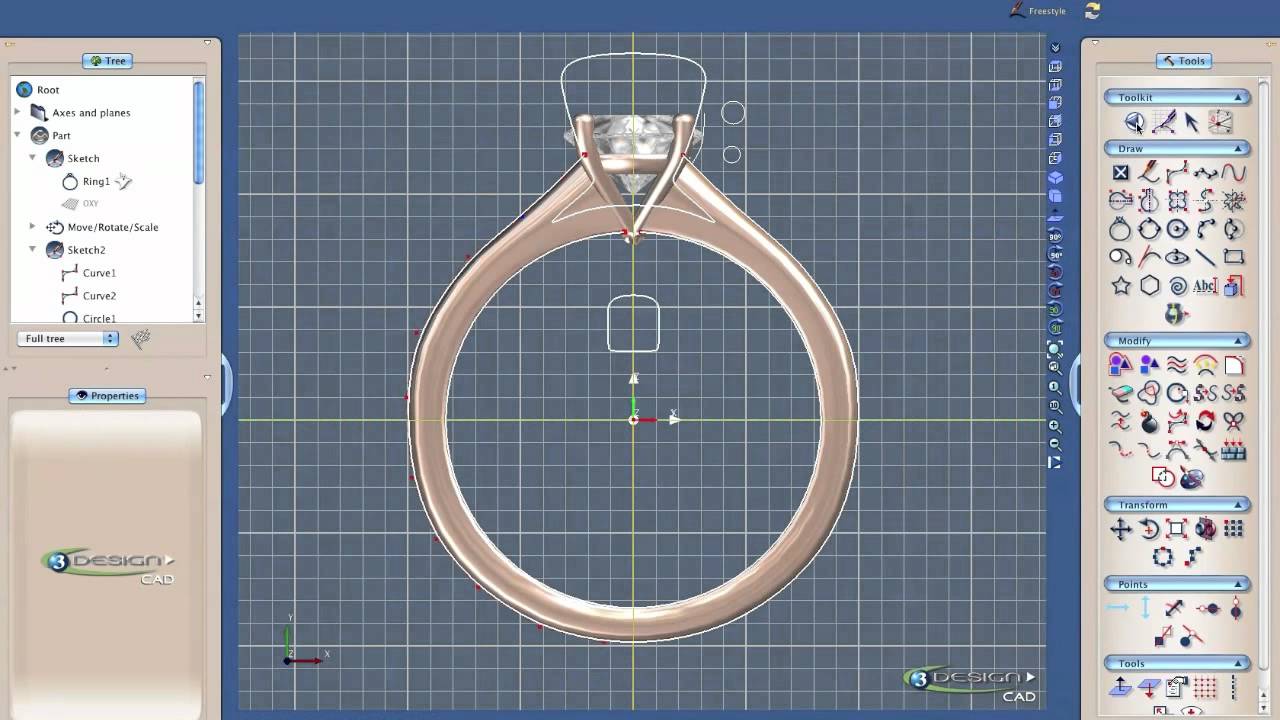

The role of CAD/CAM in jewellery design and manufacture

Until a few years ago creating 3D models involved Computer Aided Drafting (CAD) software that required powerful computers and expensive specialist software. For years CAD was too technical and completed for most people other than specialist users. CAD requires extensive training and practice to use properly.

Figure 11- computer aided jewellery design- https://www.youtube.com/watch?v=YBiFdm2-h5w

Much user friendly, lower cost alternatives have been developed for home users. A large percentage of jewellery these days is designed by CAD software. It enables to designers to be able to work more rapidly, assist in creating variations in a similar design theme and add motifs into various projects more easily than it would be to draw by hand. CAD allows the designer to save all the data in a library which can be potentially used in future for desired functional elements.

CAD has made the designing process so lenient where a complex piece of jewellery can be zoomed in to get every detail required in even the smallest areas of the jewellery piece. Conventionally this may require several hours to add detail in such manner.

The creative process is also enhanced with the help of CAD. The creativity is achieved by considerable experimentation of a good design. CAD allows you to undo anything that does not look good for a finished piece. The ability to be able to see a piece before casting is a strong asset of CAD. Customers can have more of an input into how they would like their piece to look and make changes. It gives easy access to designer towards their imagination and inspiration without any hassle and time consumption.

However, as much as CAD provides an element of freedom and precision, sometimes, especially for sculptural pieces, it’s best to use hand carving skills to create more organic pieces and free flowing design process. Sometimes pieces are created by accident during the physical making process, these can sometimes be the better creations.

There are three types of 3D printing available; Fused deposition modelling, Laser sintering and Stereolithography

Fused Deposition Modelling (FDM)

FDM is a process, where a model is created by heating thermoplastic filament which is heated to its melting point and then extruded, created layer by layer to create a three dimensional object. Most 3D printers work on FDM, as they are more widely available and easy to find.

Laser Sintering

Sintering involves the heating of metal powders to their melting point to form complex solid objects. This innovation has revolutionised the jewellery design industry. With this technology, powdered metals like gold, silver and platinum can be easily melted with the help of a laser in layers to form the desired design. It enables production of pieces such as workable hinges, clasps and pins. This technology is still expensive and relatively new, but may eliminate the process of creating wax moulds and casting.

Stereolithography

Stereolithography (known as SLA or SL) also uses a similar process to the FDM process but instead of extruding plastics, the process uses an ultraviolet light beam to harden a model from a pool of photosensitive liquid. This allows for a higher quality printout with high accuracy and the smoothest surface finish.

Health & Safety Risks with 3D Printers

When using 3d Printer, extruders, plastics and in some printers, the print bed itself can get very hot and can cause bad burns if you are not careful. Some printers have no enclosure around the print area which can lead to exposure of the skin to burns.

It is important to keep your 3D printer in a well-ventilated room as during the printing process, noxious fumes are emitted from the plastic material used.

Advantages/Disadvantages

The Advantages of 3D printing means faster production from design to manufacture, less waste is made from production, it is more cost effective for mass produced items as pieces are produced faster. Bench skills are not required to produce jewellery using a 3D printer, enabling people to be able to become jewellery producers without the skill set required for traditional jewellers. Mistakes and amendments can be easily made before printing and alterations such as engraving. Designs can be saved digitally and replicated. Also customers can have more of an input as they are able to see the design before printing.

There also disadvantages of 3D printing; there are size restrictions, at the moment 3D printers are limited to create smaller items. Defects and errors can occur during printing, the cost of a 3D printer and software can be expensive, especially for a small time jeweller. Jewellery produced by a 3D printer is not handcrafted and less personal. 3D printers will reduce the amount of jobs available as they become more widely used in the manufacture of jewellery. Copyright issues may arise as 3D printers become increasing a more popular way of producing jewellery it is also easier to produce counterfeit items. Printing material available is limited and currently unable to print to metal without sintering so casting is still required. CAD knowledge is required to produce designs for printing using 3D printers.

Sustainability

Traditional jewellery had been known to have a poor record with regards to ethical and environment issues when sourcing raw materials but jewellery designers and customers are increasingly interested in buying/producing sustainable and ethically-sourced materials and products.

There is a possibility that 3D printing will reduce waste and increase efficiency, making 3D manufacturing more sustainable with possible environmental and economic benefits as products are produced more efficiently and less material is required. Shipping costs and transportation requirements will change as parts and products will be able to be manufactured locally.

Products will be built to last longer and 3D printers will have the ability to repair existing products, helping to reduce landfill with less waste materials.

Material Cost Savings

3D-printing technology has the potential to make the manufacturing process extremely precise. Currently if you want a part made out of aluminum, a block is placed into a CAD system and the excess material is cut away to make the part. Using this process, approximately 60 to 70 percent of the aluminum block ends up as scrap depending on the complexity and shape needed. The scrap is later melted down and reused for future manufacturing needs. By contrast, 3D-printing technology is “additive,” and manufacturers are able to use the minimum material needed to fabricate a part. A 3D printer could essentially eliminate the process of melting down excess scrap material and wasted resources, ultimately driving down total material costs for the manufacturer. For the manufacturing industry in general, this could significantly reduce capital tied up in raw materials and costs to reclaim scrap.

Few studies have examined the variety of environmental impacts of 3D printing, such as energy use, transportation costs, and pollution, compared with traditional manufacturing. Further research on a larger scale is needed. It is expected that sustainability professionals, especially in industry sectors, such as consumer products and electronics, automobiles and medicine, will be tracking 3D printing developments.

Chapter 3 – Future market

Traditional Jewellers

There are still many traditional designers and jewellers who use traditional techniques of sand casting and lost wax casting.

Melissa Yarlett is a traditional jeweller who uses sand casting and lost wax casting creating organic and ethereal jewellery. She strongly believes in making individual and bespoke pieces. Melissa never replicates any of her jewellery exactly, they are all bespoke and different.

Harriet Kelsall is an award winning jewellery designer who combines traditional craftsmanship with cutting-edge technology using CAD. Harriet, an advocate for strong ethical values, was a finalist at the UK Jewellery Awards for Ethical Jewellery Business of the Year 2017.

Ruth Thomlinson, a traditional jewellery designer is considered by industry experts as one of the leading influences in the current generation of UK jewellery designers and is committed to sourcing materials in an ethical and sustainable manner.

Many traditional jewellers offer to redesign old jewellery pieces, such as family heirlooms that are broken or not to their taste, transforming them into new contemporary designs.

3D printing companies

A growing number of innovative companies are experimenting with 3D printers, propelling the technology closer to the mainstream market.

Some high end brands are beginning to use 3D technology in their designs including Chanel who have admitted to using a form of 3D printing sparingly their jewellery workshops. “3D technology is a tool to help interpret a complicated design, for example, a very intricate clasp or a perfectly symmetrical piece,” explains Chanel purchasing and development director Georges Amer. But Amer points out that 3D printing is the exception, not the norm. “We encourage the development of the best traditional jewellery-making skills by asking our craftsmen to be able to create a piece entirely by hand.”

American Pearl is one the largest companies in America who experiment with 3D printers, their customers are able to create a unique piece of jewellery by choosing specific metals, gems, or diamonds, ordering them online, and then 3D printing them. However, the service is quite expensive — the company is making jewellery that costs hundreds of thousands of dollars.

Electrobloom is a UK design company that creates contemporary jewellery using traditional craftsmanship techniques, digital tools and manufacturing technologies. Pieces are digital manufactured and then finished by hand. Electrobloom have designed for Asprey, Vivienne Westwood, Paul Smith and Matthew Williamson.

Raymond Graff, director of production at Graff, invested in two 3D printers for the company’s Bond Street workshop, allowing components of designs modelled using CAD to be printed in resin and cast in precious metal. “When I said to the guys in the workshop, ‘I just saw the most amazing machine,’ their faces all dropped,” recounts Graff. “They said, ‘The machine is going to take our jobs,’ and I said, ‘Not at all, it’s going to help you’. Six months later I had to go and buy another one. That’s technology for you. If you don’t move with it, you get left behind.”

Chris Anderson, author of ‘Makers; The New Industrial Revolution’ states “3D printing are still a bit expensive and hard to use; it’s not yet for everyone. We haven’t really figured out what the killer app will be. But what we do know is that it will get better and cheaper even faster than the laser printer did”, “Soon these early tools will become ubiquitous and easy to use as ink jet printers. And if history is any guide it will change the world even faster than the microprocessor did a generation ago. We are all designers now. It’s time to get good at it”.

Some experts in the industry feel that 3D printing will be hugely disruptive, while others believe the technology is decades away from viability.

Forecasts project significant growth in the industry over the next five years. As stated by the website On 3D Printing, “The 3D printing industry is expected to change nearly every industry it touches, completely disrupting the traditional manufacturing process. As a result, the projected value of the industry is expected to explode in the near future.”

How these technological advances will affect myself as a traditionally trained jewellery designer

I am passionate about producing jewellery using traditional handcraft methods and enjoy using my creative and artistic talents to produce individual one-off pieces. If I were to have a successful business that required me to reproduce items of the same design then I would consider adopting technology such as CAD and 3D printing in the future, this would also depend on commercial pressure and customer demand.

There are far more job vacancies for CAD technicians and CAD designers than there are traditional jewellery designers which may lead to jewellery designers becoming more technically aware and qualified.

Conclusion

Over time industrial additive manufacturing will drop in price and will open the market for more affordable products, but this will take some time. Similarly, the capability of home 3D printing technologies will remain limited for many years, with current technologies lacking in accuracy and scale and the ability to produce sturdy parts in a sufficient variety of materials to make desirable consumer products, however this may change in time. Consumer 3D scanning and printing is not capable of producing exact replicas of objects and it will be a number of years until the technology is capable of this. Due to the poor quality of the digital models that are created and the type of products that are being scanned at present, brands and designers will be unconcerned about the impact that scanning will have on their business. Forecasters predict the 3D industry will impact nearly every industry when the market grows and the cost of printers fall, this will make a complete shift in the way manufacturing is done.

Eventually, people will be able to make whatever they need in their own homes, yet technologies are only as good as the people using them. Will people be able to fabricate their own jewellery using 3D printers without specialist skills and training? Technologies are only as good as the people using them, skill sets will have to change to include computer and software technologies.

Computers can refine many automated processes increasing speed, efficiency and precision, narrowing or eliminated margins of error. Even in a shop where jewellers do most work by hand computers can help to make clasps and findings, giving the goldsmith more time to be creative.

Technology can increase complexity of designs, enhance the ability for jewellers to interpret more artistically ideas as capabilities increase. Many designers still use the conventional methods of making jewellery despite the introduction of modern manufacturing using CAD and 3D printers especially when making high-end personalised pieces, good craftsmanship skills are still required and essential when adding detail and giving a perfect finish.

So what does this mean to the jewellery business? It means high volume products, cheaper products, high quality and highly repetitive products can be produced for large scale jewellery businesses but as long as customers are willing to pay a premium for the handmade jewellery for quality, individuality and beauty there will still be a requirement for the handcrafted jeweller.

In my opinion technology, especially 3D technology, will grow and may advance in the mass production of jewellery, with more of the larger jewellery designers starting to use 3D printers but there will always be a need for high end jewellery produced using traditional methods for customers who want special one-off pieces. Technology can be used to enhance traditional crafts such as manufacturing of standard fixings and specialist pieces, but there will always be a demand for designers, hobbyists, small businesses and their artistic skills and interpretation of jewellery. The way traditional methods taught today to new jewellers is unlikely to change but new skills of 3D printing and CAD is likely to be an additional skill to learn.

Technology will always be used as a driving force to improve repeatable high-end quality products but can never replace the artistic interpretation of talented individuals. Technology makes the processes faster, easier and more cost-effective but will never replace creative ability and imagination.

Anderson, C., 2012. Makers. s.l.:Random House Business Books.

Anon., 2012. Materializing information: 3D printing and social change. [Online]

Available at: http://firstmonday.org/ojs/index.php/fm/article/view/3968/3273

[Accessed 30 November 2017].

Anon., 2017. 3D print HQ – How Does Laser Sintering Work?. [Online]

Available at: https://3dprinthq.com/how-does-selective-laser-sintering-work/

[Accessed 31 december 2017].

Anon., 2017. How does selective Laser Sintering work?. [Online]

Available at: https://3dprinthq.com/how-does-selective-laser-sintering-work

[Accessed 31 December 2017].

Anon., n.d. Is CAD the new future of jewellery design?. [Online]

Available at: https://www.londonde.com/blogs/is-cad-the-future-of-jewellery-design/

[Accessed 31 december 2017].

Anon., n.d. What is 3D printing?. [Online]

Available at: http://3dprinting.com/what-is-3d-printing/

[Accessed 30 November 2017].

Besten, L. d., 2012. On Jewellery. s.l.:ARNOLDSCHE Art Publishers.

Bethany C. Gross, J. L. E. S. Y. L. C. C. a. D. M. S., 2014. Evaluation of 3D Printing and Its Potential Impact on Biotechnology and the Chemical Sciences. [Online]

Available at: https://pubs.acs.org/doi/ipdf/10.1021/ac403397r

[Accessed 30 December 2017].

Cook, A. C. a. C., 2013. Freight miles: The impacts of 3D printing on transport and society. [Online]

Available at: http://eprints.lancs.ac.uk/66198/1/Freight_Miles_Report.pdf

[Accessed 20 November 2017].

Cooksongold, 2009. Starting and furnishing a Jewellers workshop. [Online]

Available at: https://www.cooksongold.com/blog/jewellery-tips/starting-furnishing-a-jewellers-workshop

[Accessed 30 November 2017].

Electrobloom, n.d. About. [Online]

Available at: http://www.electrobloom.com/about/

[Accessed 6 January 2018].

Goodall, C., 2012. Sustainability. s.l.:Hodder & Stoughton.

Hausman, R. H. a. K., 2013. 3D printing for dummies. 2nd ed. s.l.:s.n.

Hod Lipson, M. K., 2013. Fabricated: The New World of 3D Printing. s.l.:John Wiley & Sons.

Hoskins, S., 2013. 3D Printing for Artists, Designers and Makers. 1st ed. s.l.:Bloomsbury.

Jamaluddin, A., n.d. 10 things you need to know before buying a 3D printer. [Online]

Available at: https://www.hongkiat.com/blog/things-know-buying-3d-printer/

[Accessed 4 January 2018].

Marsh, P., 2012. The new industrial revolution. s.l.:Yale university press.

Matt Ratto, R. R., 2012. 3D printing and social change. [Online]

Available at: http://firstmonday.org/ojs/index.php/fm/article/view/3968/3273

[Accessed 31 November 2017].

Megazzini, L. M. a. M., n.d. The role of CAD/CAM in the modern Jewellery business. [Online]

Available at: http://www.allsaints67.lancsngfl.ac.uk/download/file/Curriculum/ICT/Applied/Unit%201/SS%20Cwk/CAD-CAM.pdf

[Accessed 31 November 2017].

Phil Reeves, D. M., n.d. The Current Status and Impact of 3D Printing Within the Industrial Sector: An Analysis of Six Case Studies. [Online]

Available at: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/413673/The_Current_Status_and_Impact_of_3D_Printing_Within_the_Industrial_Sector_-_Study_II.pdf

[Accessed 30 December 2017].

Royce-Greensill, S., 2015. Is 3D printing the future of fine jewellery?. [Online]

Available at: http://www.telegraph.co.uk/luxury/jewellery/is-3d-printing-the-future-of-fine-jewellery/

[Accessed 4 January 2018].

Susmita Bose, S. V. a. A. B., 2013. Bone tissue engineering using 3D printing. [Online]

Available at: http://www.sciencedirect.com.ezproxy.herts.ac.uk/science/article/pii/S136970211300401X

[Accessed 5 December 2017].

Taylor, A. B., 2014. Rolling Mill Know-How Part Two: Tips on Use, Care, and Maintenance. [Online]

Available at: http://riograndeblog.com/rolling-mill-know-how-part-two-tips-on-use-care-and-maintenance/

[Accessed 20 November 2017].

Untracht, O., 1982. Jewelry Concepts and Technology. s.l.:RBJT6.

Illustrations

Figure 1 – 158mm Double Combination Rolling Mill – https://www.riogrande.com/product/158mm-double-combination-rolling-mill/113549

Figure 2 -Tapering Wire Using a Rolling Mill – https://www.youtube.com/watch?v=ML2en0Suhvw

Figure 3 – creating texture using a rolling mill – https://www.pinterest.co.uk/pin/220606081721888844/?lp=true

Figure 4 – Die Springs- https://www.globalspec.com/learnmore/mechanical_components/springs/die_springs

Figure 5- hand engraving – http://www.lindensjewelry.com/engraving

Figure 6 –Jewellery Milling Machine – https://www.youtube.com/watch?v=jDuHDUWsdZ4

Figure 7 – Wax Jewellery Milling – https://www.youtube.com/watch?v=ZJJyvl55QHI

Figure 8 – lost wax casting – http://www.sandipointe.com/im/arts-crafts-sewing/lost-wax-casting-11.jpg

Figure 9 – Jeweller’s Bench – https://www.cooksongold.com/Jewellery-Tools/Jewellers-Bench-Birchwood-prcode-997-120B

Figure 10 – 3D Printer – https://www.lulzbot.com/store/printers/lulzbot-taz-5#&gid=2&pid=3

Figure 11- computer aided jewellery design- https://www.youtube.com/watch?v=YBiFdm2-h5w

You have to be 100% sure of the quality of your product to give a money-back guarantee. This describes us perfectly. Make sure that this guarantee is totally transparent.

Read moreEach paper is composed from scratch, according to your instructions. It is then checked by our plagiarism-detection software. There is no gap where plagiarism could squeeze in.

Read moreThanks to our free revisions, there is no way for you to be unsatisfied. We will work on your paper until you are completely happy with the result.

Read moreYour email is safe, as we store it according to international data protection rules. Your bank details are secure, as we use only reliable payment systems.

Read moreBy sending us your money, you buy the service we provide. Check out our terms and conditions if you prefer business talks to be laid out in official language.

Read more