TABLE OF CONTENT

1. Introduction………………………………………………….3

1.1. Company background…………………………………………3

1.1.1. Ford………………………………………………….3

1.1.2. Toyota………………………………………………..3

2. Globalization strategies………………………………………….3

2.1. Generic strategies ……………………………………………3

2.1.1. Ford………………………………………………….3

2.1.2. Toyota………………………………………………..4

2.2. Joint venture……………………………………………….4

2.2.1. Ford………………………………………………….4

2.2.2. Toyota………………………………………………..4

2.3. Integrative strategies………………………………………….5

2.3.1. Ford………………………………………………….5

2.3.2. Toyota………………………………………………..6

3. Manufacturing/technology interface …………………………………7

3.1. Ford manufacturing…………………………………………..7

3.2. Toyota manufacturing…………………………………………7

3.3. Ford (American) vs Toyota (Japan)……………………………….8

4. Marketing/technology interface…………………………………….9

4.1. Marketing mix………………………………………………9

4.1.1. Ford………………………………………………….9

4.1.2. Toyota………………………………………………..10

4.2. Intensive marketing strategy…………………………………….11

4.2.1. Toyota ……………………………………………….11

4.2.2. Ford …………………………………………………11

5. Organization/technology interface ………………………………….12

5.1. Organization structure…………………………………………12

5.1.1. Ford………………………………………………….12

5.1.2. Toyota ……………………………………………….12

5.2. Organizational culture…………………………………………13

6. Conclusion…………………………………………………..15

7. References…………………………………………………..16

TABLES AND FIGURES

Table 1. Ford Marketing Mix………………………………………..9

Table 2. Toyota Marketing Mix………………………………………10

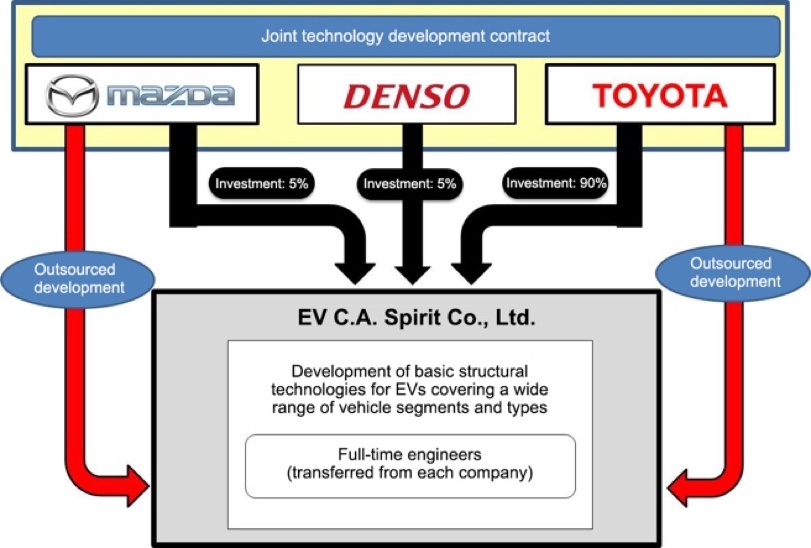

Figure 1. Toyota Joint Venture with Denso and Mazda………………………5

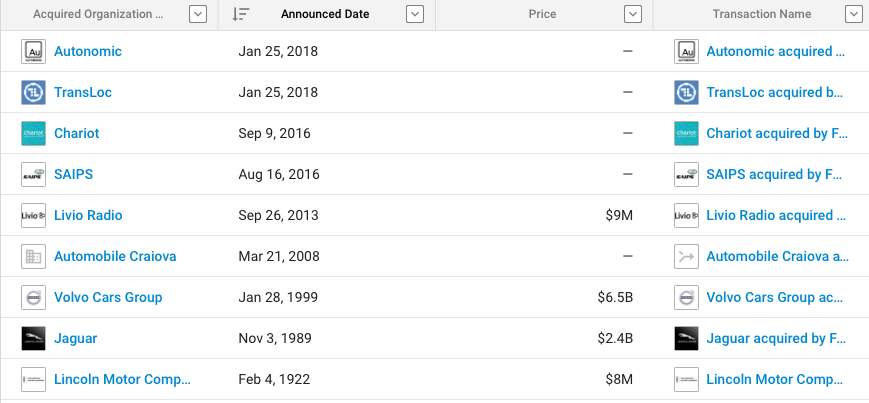

Figure 2. Ford acquisitions………………………………………….6

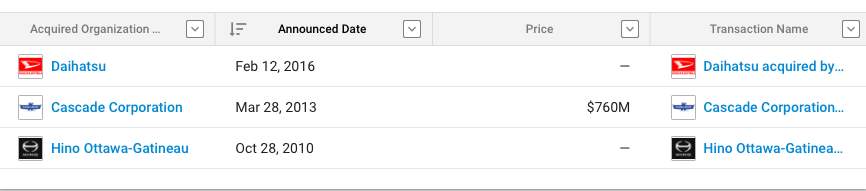

Figure 3. Toyota acquisitions………………………………………..6

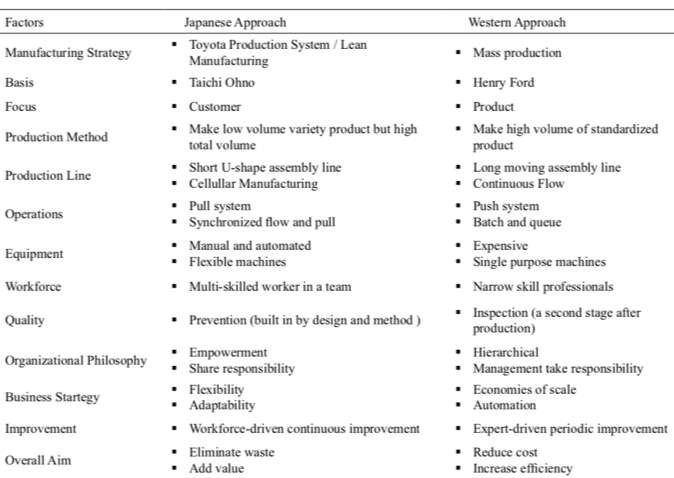

Figure 4. Ford VS Toyota Manufacturing Strategies………………………..9

Figure 5. Differences in management and organization characteristics between Japan and Western 14

Figure 6. Japanese VS Western Culture…………………………………14

Ford or The Ford Motor Company, founded in 1903 by Henry Ford in Dearborn, is an American multinational automotive company currently become one of the global automotive leader. The idea of mass production was coming from this company. Ford succeed producing the affordable car for American middle-class society by introducing its new method, large-scale management and manufacturing, utilizing the moving assembly line in 1914. Fordism is the name of this method. (Letha, 2013)

In 2010, Ford occupied the top 5 in the category of the largest automotive company in the world (ACEA 2010). Ford produced 5.532 million automobiles with its 213,000 workers worldwide in 2008 (Ford Motor Company 2008). Ford bought Jaguar in 1989 and Land Rover in 2000, were later shifted to Tata Motors in March 2008. Next, Volvo, the Swedish automotive company, had been owned by Ford Volvo between 1999 and 2010 (Dearborn 2010). Due to the financial problem, Ford stopped its Mercury Brand (the luxury car which had promoted since 1983). Moreover, the financial crisis at the initiation of the 21st century let Ford sell its trendy trademarks like Jaguar and Volvo, in order to concern in enhancing its essential products and attracting customers to pay attention to Ford cars again. (Hammond 2011).

Toyota is a Japanese automotive company headquartered in Toyota, Aichi, Japan with Kiichiro Toyoda as the founding father. Built in 1937, Toyota has 364,445 employees spread all over the world and belongs to the 5 largest automotive companies in the world (Fortune 2017). In 2012, Toyota announced that it has produced its 200 millionth vehicle (Flynn 2012). Furthermore, Toyota is also present as one of the big companies that push for the use of hybrid vehicles and also as a market leader in the sale of hybrid electric vehicles. In addition, it also attended as a leader for the production of hydrogen-fueled vehicles. Toyota reaches 10 million milestones in total sales of hybrid vehicle models in January 2017. Its Prius family is the world’s top selling hybrid nameplate with over 6 million units sold worldwide as of January 2017 (Toyota Europe Newsroom 2017). Toyota brand, Hino, Lexus, Ranz, and Daihatsu are the popular brands of Toyota Motor Corporation. It also holds a 16.66% stake in Subaru Corporation, a 5.9% stake in Isuzu, as well as joint-ventures with two in China (GAC Toyota and Sichuan FAW Toyota Motor), one in India (Toyota Kirloskar), one in the Czech Republic (TPCA), along with several “nonautomotive” companies. (Toyota 2018) TMC is part of the Toyota Group, one of the largest conglomerates in Japan.

Since the publication of Michael Porter’s Competitive Strategy, many experts on strategy have been extolling the virtues of pure generic strategies. Porter argued that by adeptly pursuing cost leadership, differentiation, or focus strategies, businesses can attain significant and enduring competitive advantages over their rivals (Miller 1992).

Ford always adjusts its business strategy with existing market conditions. Cost leadership was Ford’s first supported strategy for Ford to face global competition by reducing production costs and offering low product prices that can attract many consumers (Meyer 2017). In the 1900s, making cars at affordable prices for all workers in America was Ford’s vision. In its application, the company built an assembly method that focuses on reducing production costs and maximizing productivity. However, this strategy was not able to keep Ford in competition. General Motors competed with Ford to become the largest automotive company in America. GM not only offers a low price, but also has a broad differentiation strategy to offer a wide variety of stylist products to consumers. So, Ford is now following GM’s lead with the release of One Ford plan, Ford is still maintaining its cost leadership, but the firm is moving toward the broad differentiation of generic strategy to compete against firms like GM and Toyota. Thus, a strategic objective based on Ford’s current generic strategy adjustment is the product innovation to gain stronger competitive advantage. Ford uses a differentiated strategy in operating its business with the goal of targeting more market segments and applying marketing mix in each segment. Ford is focusing its product development for the use of various consumer circles as well as paying attention to their various needs. Hence, Ford produces a variety of products such as luxury cars, sports cars for racers, business trucks, a daily car economy, and even Ford to produce Ford Fiesta cars designed specifically for young people and women. (Letha, 2013). Ford’s vehicle portfolio includes automobiles, buses, tractors, and trucks.

Similar with Ford, Toyota combines its strategy by focusing on cost leadership and product differentiation (Thompson 2017). Toyota is trying to reduce operating costs so that product prices can also be suppressed. In addition, variations on the product are also a concern for companies to face competitive advantage. The combination of these generic strategies supports Toyota’s global reach in all market segments. Toyota adopted the just-in-time (JIT) or Toyota Production System principles in its production line with the goal of reducing inventory costs, reducing waste and response time so that the company obtains maximum efficiency (Toyota Japan 2008; Liker 2005; Sutherland et al 2008). Moreover, Toyota upholds innovation in the company which can be a trigger to create the unique and attractive product for all of customers. Thus, Toyota fulfills its generic strategy.

Joint ventures became one of Ford’s global strategies. Ford has joint-venture relationships in several countries, such as in China (Changan Ford), Russia (Ford Sollers), Turkey (For Otosan, and Thailand (Auto Alliance Thailand) (Shen 2017). Currently, Ford plans to develop a joint electric vehicle with Anhui Zotye Automobile. This is the new joint-venture between Ford and its China fellow. This agreement will produce products with local brands, not with Ford brand, with the intention of attracting many consumers in Asia, especially China. In addition, this is a strategy for Ford to avoid paying high import duties on vehicles if Ford produces it in its home country. (Etherington 2017)

Similarly, with Ford, Toyota is using joint-venture to expand its business. Currently, Toyota plans to develop basic technology for electric vehicle production with alliance with Mazda and Denso. Not only that, they will also reduce costs and lead times in the production process. The three companies will develop a variety of vehicle models from small vehicles for daily use to trucks for business purposes. It aims to attract customers in all segments and adjust the existing market trends (Toyota 2017).

Figure 1. Toyota Joint Venture with Denso and Mazda

Source: (Toyota 2017)

There are two strategies for integration strategy, namely vertically and horizontally. A vertical strategy is a situation where a company has its own supply chain by buying / acquiring suppliers / distributors. This strategy benefits companies because the company can control and ensure the entire supply chain process and can avoid the ‘hold up’ issue; conditions in which the supply chain experienced delays resulting in loss profit (Hill & Jones 2012). On the other hand, horizontal integration is a strategy for companies where they acquire or merge with their competitors to achieve competitive advantage through economies of scale and scope (Fresard et al., 2014).

Vertical Integration

Ford founder Henry Ford developed vertical integration strategy because when he tried to fix parts and materials, he felt that inventory costs were too expensive (Nellore, 2001). Hence, he decided to control the entire supply chain by owning the whole of them (Wrye 2010). In 1927, Henry Ford built The Ford River Rounge Complex, a factory that has a vertical integrated supply chain that ensures high level control in the production process. Ford owns its iron ore and coal to produce Ford steel. Ford also owned its timberlands, glass plants, rail lines and rubber plantations, which helped to ensure efficiency, availability of necessary components as well as control over inputs and outputs (Slywotzky, 1996). However, to face competitive advantage, ford revamps its in-house component operations toward outsourcing (Nogues, 2002). However, Ford still uses a strong mix of vertical integration strategies, which account for 50% of parts production (Shuman, 2001)

Horizontal Integration

The most popular case is when Ford acquired Volvo car, the automobile operations of Swedish-based Volvo for $6.45 billion. Buying Volvo means Ford will greatly intensify competition in the luxury market through their ability to use Ford parts in Volvos, and rationalise distribution, delivering Volvos through Ford’s own network (Bradsher, 1999). However, lately Ford released Volvo for not reaching a target of its market (Dunne, 2016).

Below are several acquisition of Ford:

Figure 2. Ford acquisitions

(Source: Crunchbase1 2018)

Outsourcing

Unlike Ford, which has its entire supply chain, Toyota has chosen its own way by leveraging vertical integration without being fully outsourced. Toyota only controls sharply every action its suppliers are making on the quality of materials for their products, health and financial condition, and Toyota does not hesitate to spend much time and money to ensure their efficiency and survival. In 1980s, Toyota partnered with Johnson Controls for supply seats. Toyota did not give up their jobs completely, but also worked in production processes, rearrange production floors, and cut inventories. The approach is also far cheaper than the traditional vertical method of owning suppliers outright, a virtue at a time when cash and credit are rare. (Extra, 2009)

Horizontal integration

Currently, Toyota intend to develop Daihatsu into a global brand as they focus on growing markets for compact cars, noting that entry-level car markets were expanding due to economic development and that vehicles were becoming smaller due to environmental and traffic concerns.

Acquiring full control of Daihatsu, of which Toyota currently owns 51.2 percent, will allow it to better leverage the lower-cost brand and enable Daihatsu to more easily adopt next-generation technologies developed by Toyota. (Tajitsu, 2016)

Toyota’s acquisition of Daihatsu will strengthen its position in emerging Asian countries over the long term. As the company rolls out a line of small cars, it can tap into the opportunity in India, China and South East Asian countries. The full acquisition of Daihatsu furthers the strategic direction towards these goals. (Speculations, 2016). Below are the current several acquisition of Toyota:

Figure 3. Toyota acquisitions

(Source: Crunchbase 2018)

At Ford, automotive body construction is increasingly robotic, about 95% of the process is automated, says Chief Technology Officer Raj Nair, and the people who work on the line are highly trained and specialized technicians. To meet its customers requirement, Ford is enhancing global manufacture and growing its advanced manufacturing competences. The launching of the first moving assembly line by Henry Ford and team was the great history for manufacturing industry. This latest innovation transformed fabrication and declined the assembly time from 12 hours to about 90 minutes for a single vehicle. Ford experienced the benefit of this in its Model T production which could drop the price became below $300 from $850 initially because Ford succeed dropped the cost, time, and human energy in its production. Ford is well aware of the benefits of advanced manufacturing to build the company’s future. Hence, Ford Engineers concern to patent its technology and develop the highly flexible manufacturing. Ford’s technology will lesser prices and rapid distribution periods for prototype printing casts, within three business days versus two to six months for prototypes made using conventional methods; known as Ford Freeform Fabrication Technology. Additionally, Ford is growing its proficiencies in 3D printing, which creates production-representative 3D parts layer by layer for testable prototypes. With 3D printing, Ford can create multiple versions of one part at a time and deliver prototype parts to engineers for testing in days rather than months.

Ford also is investing in robotic innovations to improve vehicle quality and production efficiencies. For example, the company’s new dirt detection system uses robotic vision to create a digital model of each vehicle in final assembly to analyze paint and surface imperfections in comparison with a perfect model. The result has been significantly improved surface quality on Ford vehicles and more time for operators on the assembly line to tackle complex issues. Robotics, in this case, allow Ford to work smarter in improving products for customers and allowing workers to focus on more critical thinking tasks.

Finally, through Ford’s “virtual factory”, the company can improve quality and cut costs in real-world manufacturing facilities by creating and analyzing computer simulations of the complete vehicle production process. This includes simulations of how assembly line workers have to reach and stretch when building a vehicle to ensure the work conditions meet Ford ergonomic standards. Since the implementation of this virtual process in 2001, the number of ergonomic issues during physical builds has been reduced by nearly 20 percent.

“Technologies such as 3D printing, robotics and virtual manufacturing may live in research but have real-world applications for tomorrow and beyond,” said Paul Mascarenas, chief technical officer and vice president, Ford Research and Innovation. “We use Henry Ford’s spirit of innovation as a benchmark for bringing new technologies into the manufacturing process.”(Ford 2018)

Unlike Ford that relies on robot power to improve the performance of production lines, Toyota instead turned from the robot and replaces it with manual human power (Bloomberg). Essentially, Toyota has the principle that human beings cannot be separated from the production process, all of the senses (eyes, ears, hands, and so on) are an important part in identifying problems in the production line, providing creative solutions to fix the issues, and offering solutions best to improve company performance, especially in production line (Rothfeder 2017). Through this strategy, Toyota has two goals: to ensure that all workers understand what they are doing and provide space for them to find ways to create a process that is high quality and more efficient.

Currently, workers take over the work done robots at the above a hundred workspaces and it has reduced 10% waste on the production floor and has helped minimize production lines and is able to cut costs for chassis parts. Machines are excessive at undertaking possessions rapidly and at little price. But persons, particularly ones with the skill of executing jobs themselves—bring workmanship, insight into process design, and consistency of quality. Toyota has found that the race to decrease the human entity can end up creating activities less efficient. (Nisen 2014)

Voss & Blackmon (1998) compared about the formulation and execution manufacturing strategy between Western and Japanese companies. They found that Western corporations embraced a short-term focus while Japanese firms adopted the long-term method. Voss & Blackmon (1998) determined that Japanese firms possess both a stronger long- and short-term orientation, adopting a higher proportion of practices associated with quality management and preventive maintenance that result in higher cost allocation compared with Western companies. They also identified that Hall (1983) observed that Westerns have been branded by absoluteness, showed by their performance, by scheduling items single at one period and observing time as an external strength used to support establish their survives whilst Japan has been considered as a high-context culture, where things can be assumed even without speaking anything. In addition, Western manufacturers tend to emphasize single capability for instant service after sales and restrained price and flexibility. By contrast, Japanese firms experience limited competitive capabilities because they paid attention only to low price and design flexibility. In terms of manufacturing capabilities, Frohlich & Dixon (2001) perceived that the Japanese manufacturers focus more on price and quality, whereas Western manufacturers focus on manufacturing flexibility and service after sales. In the context of manufacturing strategy, the comparison between Western approaches based on mass manufacturing and Japanese approaches based on TPS are summarized in Figure 4.

By contrast, the mass production adopted by Western companies is concerned with production of high volume of a standardized product. The Westerners generally utilize the long moving assembly line and push system. The hierarchical structure in Western companies restricts involvement and decision-making among low-class workers, enabling the management to assume full responsibility. Overall, manufacturing in the West contains the mass markets, standard designs, and the utilization of interchangeable parts to achieve high volume of production. Continuous development in the Western manufacturing sector made the American the world’s leading producer of manufactured goods.

Figure 4. Ford VS Toyota Manufacturing Strategies

(Source: Bolwijn & Brinkman 1987 in Ab Rahman et al 2013)

McCarthy’s marketing mix has been widely adopted through time by managers and academics, becoming a key element of marketing theory and practice (Dominici 2009). In McCarthy’s version (1964), the marketing mix is composed of: product, price, place and promotion.

Ford Motor Company’s marketing mix enables the firm to reach its target customers worldwide. This marketing mix and associated strategic actions change over time to match the firm’s markets and industry environment. Below is the marketing mix table of Ford:

Table 1. Ford Marketing Mix

| TOYOTA MARKETING MIX | |||

| Toyota’s Products (Product Mix) | |||

You have to be 100% sure of the quality of your product to give a money-back guarantee. This describes us perfectly. Make sure that this guarantee is totally transparent.

Read moreEach paper is composed from scratch, according to your instructions. It is then checked by our plagiarism-detection software. There is no gap where plagiarism could squeeze in.

Read moreThanks to our free revisions, there is no way for you to be unsatisfied. We will work on your paper until you are completely happy with the result.

Read moreYour email is safe, as we store it according to international data protection rules. Your bank details are secure, as we use only reliable payment systems.

Read moreBy sending us your money, you buy the service we provide. Check out our terms and conditions if you prefer business talks to be laid out in official language.

Read more