Assessment of the effects of manufacturing practices on the delivery time in a supply chain

Abstract.

The literature suggests that nowadays companies use to evaluate the delivery time of their products/services to improve their performance in the supply chains which has had greater importance due to global competition and trends in current markets. In response, this paper analyses the effects that the manufacturing practices have on the delivery time in a supply chain. To collect the information was conducted a survey related to export activities applied in “maquiladoras” companies located in Ciudad Juarez, Chihuahua, Mexico. A questionnaire was applied to managers, supervisors and operators. The questions were grouped in three dimensions associated with manufacturing practices: 1) Just in Time (JIT), 2) Maintenance, and 3) Total Quality Management (TQM); and a fourth dimension related to the delivery time. Five hypotheses have been raised to determine the causal relationships between the dimensions analysed in a structural equation model, and tested using Partial Least Squares (PLS) technique integrated in the WarpPLS 4.0 software. The findings revealed that the JIT has a positive and greater effect on delivery time. In addition, the TQM and Maintenance have positive effects in JIT, enabling undoubtedly achieve timely delivery of products and better customer satisfaction. Additionally, respondents consider the implementation of manufacturing practices in the processes as appropriate.

Competitiveness in the environment of globalization highlights the importance of becoming more efficient in the implementation of operational and administrative processes in companies to improve customer service levels, lead time, quality in products or services, and optimize resources (Rodriguez et al., 2015).

Companies from different economic sectors adopt nowadays manufacturing strategies focused on continuous improvement to achieve positive changes in productivity and in product quality, and also in the management of their supply chains (Fuentes and Diaz, 2012). For example, these manufacturing strategies were essential on the Toyota production system created in the 70’s to achieve efficient use of resources by reducing wastes in different areas of the production process. Among the wastes are considered rework defects, unnecessary steps in the process, unnecessary material and people movements, waiting time, excess of inventory and overproduction, among others (Evans and Landsay, 2005; Womack et al., 1990). This approach has become for organizations a key factor in the adoption of tools and practices to improve their competitiveness in the market.

The manufacturing practices currently used in manufacturing companies to integrate and manage the supply chain inside and outside include: 1) Total Quality Management (TQM), 2) Just in Time, 3) Maintenance, 4) Kaizen 5) Single-Minute Exchange of Die (SMED), 6) 5S, 7) Kanban, 8) Poka Yoke, 9) Six Sigma, among others (Evans and Landsay, 2005; Shah and Ward, 2007).

JIT is defined as a manufacturing approach, firstly used in Japan, which emphasizes the importance of achieving continuous improvement in all phases of production and includes the participation of all involved parties in the supply chain, from a point of view intra-organizational and inter-organizational (Enkawa and Schvaneveldt, 2001; Olhager and Prajogo, 2012; Shah and Ward, 2007).

JIT is a concept that focuses on increasing customer satisfaction, which is a key tool to achieve better results in operational and financial performance of companies; and is a tool applicable to different industrial sectors in which substantial benefits in enterprises are obtained, this is a strong motivation to analyse the Mexican maquiladoras. By implementing JIT it is important to respond to customer needs, promote perfect production activities, and conduct adequate levels of quality, cost and delivery, and not only promote it but also execute it (Amasaka, 2008).

TQM, in turn, is responsible for organizational management focused on quality and activities of all members of the organization, to achieve success through customer satisfaction (Topalovic, 2015). The Total Quality Approach is used to integrate business operations and create products or services with the best possible quality. To be successful in the future, a global marketer must develop excellent quality management system that can impress consumer and continuously provide excellent quality products in a timely manner through corporate management for manufacturing in the 21st century (Amasaka, 2014).

Maintenance is a breeding program that establishes a system of comprehensive productive maintenance throughout the life of the equipment used in the processes, and covers everything related with the team and with the participation of employees. The purpose of maintenance programs is to achieve rapid improvement in manufacturing processes to reduce the time integrating machines and equipment together with people (Konecny and Thun, 2011).

All of them, TQM, JIT and Maintenance strive for continuous improvement, reduction of waste and performance improvement in the organization (Cua et al., 2006). By combining these techniques, a comprehensive and consist set of manufacturing practices can be derived to improve firm performance. Therefore, many manufacturing firms consider a simultaneous implementation of these improvement programs in order to achieve synergetic effects (Konecny and Thun, 2011). Several studies on TQM, JIT and Maintenance explore those improvement programs and their relationship with performance (Seth and Tripathi, 2005; Danese et al., 2011; Agus and Hassan, 2011; Topalovic, 2015; Digalwar et al., 2015). Some works have investigated existing relationships between different improvement programs empirically (Cua et al., 2006; García et al., 2014). However, some research approaches tried to identify conceptually the value of implementing and exerting different improvement programs simultaneously (Hansson et al., 2003; García et al., 2014). In this context, the purpose of this empirical study is to identify the effects of the respective programs application in manufacturing firms and to analyse the results in operational performance, which means, delivery.

Specifically, this study presents an analysis of research done to date on relationships with two basic objectives: 1) to identify the topic set studied and contribute a criterion for define the useful and successful of these practices in the field, and 2) to discuss the contributions to the implementation of these practices, any found gaps that enable us to point out any opportunities that exist for future research.

The data set is constructed from responses of a regional sample of manufacturing employees. Measurement scales are assessed for dimensionality, validity and reliability. Because the technique used to assess the model here is assessed a conventional path analysis and Partial Least Squares (PLS) technique to estimate the parameters in the model.

The study has been divided into four parts with this first part devoted to the introduction. The second part provides details of the theoretical background and conceptual framework. The third section is the methodology followed to accomplish the research objectives. Finally, in the fourth the results are discussed with reference to the contributions, industrial implications and gaps found in the model. Conclusions are also provided together with the challenges that future research will have to address and the implications of the findings for management.

According to Rungtusanatham et al. (2005), there is no consensus or a universal definition of TQM. As stated by Besterfield (1995), several and different definitions come up with academicians, scientists, engineers, practitioners, and others. TQM can be defined as “an approach that focuses on improving the organization’s effectiveness, efficiency and responsiveness to customers’ and other stakeholders’ needs by actively harnessing people’s skills and competencies in the pursuit of achieving sustained improvements to organizational performance” (Porter and Tanner, 2004, p.4). Some previous empirical studies have emphasized the role of TQM (Idris, 2011; Valmohammadi, 2011; Salaheldin, 2009; Demirbag et al., 2006; Feng et al., 2006). During the last two decades, in the area of operations management research, TQM is one of the most important subjects studied and developed, receiving high attentiveness (Jung and Wang, 2006). Also, as previously noted, many elements cited as necessary to attain this improvement are previously established elements of JIT. TQM should be implemented before lean production as say Teeravaraprug et al. (2011) and have correlation with JIT as show Kannan and Tan (2005) in their study. They find that TQM and JIT are important to improve supply chain management to response customers’ needs. Most previous studies show a positive relationship between TQM practices and business performance (Jun et al., 2006; Gunday et al., 2011; Miyagawa and Yoshida, 2010). Some of the findings also partially correlated with the business performance (Demirbag et al., 2006; Feng et al., 2006; Arumugam et al., 2008). Therefore, accordingly, in this subsection are proposed two hypotheses referred to TQM:

H1: The application of Total Quality Management program has a direct and positive effect in the Just in Time.

H4: The good practices of Total Quality Management program have a direct and positive effect in the Delivery time.

In order to reduce lead times decreasing or eliminating waste in supply chain, a series of reengineering strategies were implemented by company since the early 1980s with the implementation of just in time (JIT). The process began with reducing the lead time, next was developed a simplified and integrated approach to materials planning. In the sequence occurred the integration of the vendor base (Naylor et al, 1999). JIT in the production refers to the adoption of practices aimed at reorganizing shop floor and streamlining production flows within production plants (Furlan et al., 2010). JIT integrates the entire supply chain’s marketing, distribution, customer service, purchasing, and production functions into one controlled process.

As stated earlier, Kannan and Tan, (2005) advocate the elimination of waste by simplifying production processes. It allows reduction in set up times, controlling material flows, and emphasizing preventive maintenance to improve supply chain management. The JIT is one of the some bundles of lean manufacturing that is supported by the study of Shah and Ward (2003) to whom, that experience suggests a JIT production system is required for improvement of business performance (Ahmad et al., 2012; Konecny and Thun, 2011). Danesse et al. (2011) in their study about JIT and delivery performance found that the implementation of JIT have positive relationship with delivery, and thus companies can significantly improve their delivery performance by levering. The authors conclude that JIT in production practices positively affect the delivery. The hypothesis that arises of this implication is the following:

H3: The good practices of Just in Time system have a direct and positive effect in the Delivery time.

The maintenance program is a comprehensive improvement, originate from the concept of zero defects of TQM which is applied to control equipment performance (Seth and Tripathi, 2006). The main objective of the maintenance is to achieve a reliable manufacturing system (Ahuja and Khamba, 2008b). This is accomplished by maximizing the overall equipment effectiveness so that plant and equipment productivity is increased (Ahuja and Khamba, 2008a).

In the work of Mckone et al. (2001) it was analysed the relationship between maintenance programs and business performance using the lean production as mediator variable. The found results were that the maintenance program has positive and significant direct relationship through the production lean improving the costs, the quality and the delivery time. The maintenance programs are significantly supported by TQM for improving business performance as mentioned in the work of Konecny and Thun (2011), and also in the work of Teeravaraprug et al. (2011), who studied the relationship between TQM and TPM, finding that these should be implemented before a lean production. With these implications two hypotheses can be established related to maintenance and its relationship with the JIT and with the performance (Delivery time), as follow:

H2: The good practices of Maintenance have a direct and positive effect in the Just in Time.

H5: The appropriate management of Maintenance has a direct and positive effect in Delivery Time.

TQM and maintenance programs have similar goals: continuous improvement, waste reduction and improving performance (Teeravaraprug et al., 2011). These practices are a comprehensive set of manufacturing improvement practices directed towards improving business performance. Lean production eliminates waste through inventory control and reduction time delay of process (Fullerton and Wempe, 2009). The maintenance programs helps maximize equipment performance and prevents break-down (Breja et al., 2011) and TQM aims to maintain and improve product quality and business performance.

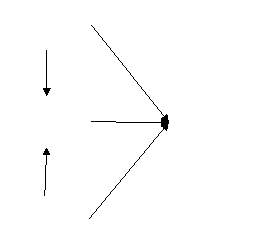

Considered the previous context and also, the studies about these subjects, in this work the proposed model and the hypotheses are shown in Figure 1. Can be observed that are proposed relationships of TQM, JIT and Maintenance with the variable Delivery, that in these cases is a performance variable of supply chain.

Figure 1. Hypotheses

For hypothesis testing, first direct contacts between manufacturing practices and the delivery time of products as part of financial performance in the supply chain were included. On the one hand, the ratio of total quality management TQM with philosophy lean, to establish a direct relationship with the JIT was considered; and also its relation with the delivery time. On the other hand, Maintenance with the JIT and its relation with the delivery time was also recorded. Finally a direct relationship of JIT with products delivery time was proposed. A priori there is no expectation about the direction of the effects suggested in the proposed model.

A survey method was used in this work to obtain the data o be used in the empirical model. Some authors argue that survey methods may provide better reliability than qualitative approaches (Babak and Saeid, 2012, Rindfleish et al., 2008), and are often adopted to discuss organizational issues. The focus of the analysis in this work is on the relationships that present the TQM, JIT and Maintenance at the time of goods delivery within the supply chain, and the way in which they can influence positively or negatively the whole process.

Manufacturing practices in maquiladoras companies as an internal process of the supply chain are very important because these kind of companies belong to global supply chains, where customers are in many countries and not only an optimal management of the external chain is required but also to find a suitable connection between the internal processes and the results in the performance of it. To find this connection, first it is necessary to know the current status of the use of tools to improve production processes that is how the idea came to study the maquiladoras, because practical aspects of implementation of these tools are not known or studied yet.

Maquiladoras in Juarez are companies focused on export manufacturing, which transform raw materials into finished products in Mexican territory, and that subsequently are exported to their country of origin. Maquiladoras are considered, collectively, platforms of manufacture of highly competitive products between the United States and Mexico.

In Mexico this kind of companies has increased over the years since the commercial opening in the 70s with the North American Free Trade Agreement (NAFTA) was developed (Avelar et al. , 2015). According to the results presented by the AMAC (Maquiladoras Association, AC from Ciudad Juarez, Chihuahua, Mexico), until June 2015 maquiladoras were 318 active companies, a few less than previous year (324 in June 2014), and which represented the occupation of 241,867 people in the city, corresponding to 9.61% of the total national employment (AMAC, 2014).

Historically, the manufacturing industry has accounted for 20% of the Mexican GDP (Gross Domestic Product) in recent years, and as regards the employment the manufacturing activities have represented between 8% and 10% of the national employment (Siller and Nuñez, 2015; INEGI, 2015). For these reasons, the manufacturing sectors are highly relevant for the Mexican labor market, once with this performance have been able to improve the economic growth of the country and particularly of the studied region.

Considering the number of active companies it was possible to contact them to the application of the questionnaire. The potential people to be surveyed came from the AMAC and were composed by engineers, managers, supervisors who were working in related areas with manufacturing practices and supply chain. Many potential people to be surveyed expressed that they would like to have the questionnaire in electronic version and then the file was sent them via email. However, not all the questionnaires were answered on the first visit that was made to the workplace of potential respondents.

To carry out this study it was necessary to determine the size of the target sample in order to achieve adequate statistical power. To the survey a simple random sampling was used to consider all, the active export manufacturing firms of Ciudad Juarez during 2014, among which 324 companies were identified.

Later it was considered a stratified sampling focused on companies that have some level of implementation of manufacturing practices because these companies can identify and confirm the activities needed to attain higher profits in the system Just in Time, in Total Quality Management, in the Maintenance program and relate them to the time of products delivery.

The survey was directed to staff working in the maquiladoras areas of supply chain, including purchasing and supplier planners, supervisors, engineers, managers and directors of operations, because these are people who have more reliable information about these issues (Foster et al., 2011).

Moreover, the literature suggests that in studies where structural equation modeling is used, a sample size of 4 to 5 observations by parameter is required (Bollen, 1989). In this case, the proposed model is evaluated with the Partial Least Squares method, so that the sample size requires at least 100 cases to reach the level of statistical power (Reinartz et al., 2009). The results on the sample size were satisfactory to achieve 225 completed surveys.

The measurement approach for each theoretical construct in the proposal model is described in the following subsections. It was considered multi-item scale and five-point response formats were used to operationalize all activities. The activities should be answered on a Likert scale, which included values between 1 and 5 (Likert, 1932), technique used in recent and similar studies (Avelar et al. 2014, García et al. 2014, Soin, 2004). No additional activities or benefits were added to the initial questionnaire. The initial survey was applied to 25 engineers working in manufacturing industries and that were laboring in manufacturing production process and had collaboration activities in the supply chain; this test was applied to give a judge validation to the survey. All the items forming the constructs were adapted from a scale as Sohal et al. (2005), and in some cases validated from other authors.

3.3.1 Total Quality Management: TQM

The total quality management refers to the use of certain tools that the company uses in processes to integrate the quality operatively in the processes as of control after completion. This construct was formed by three items taken and used by Bhatnagar and Sohal (2005) and by Soin (2004) as well:

TQM43: Our company always apply statistical process control.

TQM44: Our company always applies quality audit processes.

TQM45: Our company always applies the Six Sigma methodology in the processes.

3.3.2 Just in Time: JIT

The JIT system is a tool of lean manufacturing approach created by Toyota, and aims to eliminate waste throughout the entire production system to improve the results in the delivery of products. This construct is comprised of two items that were taken and adapted from Bhatnagar and Soha (2005) and Soin (2004) studies:

JIT46: Our company uses Just in Time philosophy in all manufacturing processes.

JIT47: Our company is always focused on the inventories reduction.

3.3.3. Maintenance: Maint

The Maintenance in turn, is made up of three items that address the use of programs of preventive and predictive maintenance in companies in order to find their contribution to the productive system. This construct was adapted from the works of Bhatnagar and Sohal (2005) and Bhatnagar et al. (2003).

Maint48: Our company offers preventive and predictive maintenance programs.

Maint49: The performance of preventive and predictive maintenance programs is effective.

Maint50: Rapid changes in the processes within the company are effective and efficient.

3.3.4 Delivery time: Delivery

This construct consists of two items and is characterized by evaluating the timely deliveries achieved by the company in order to also accomplish the many requirements of its customers. It was included to analyse a fragment of supply chain performance and was adapted from Bhatnagar and Sohal (2005) and Bhatnagar et al. (2003).

Delivery54: Deliveries of our products are made using Just in Time philosophy.

Delivery55: The company always provides complete orders.

In conclusion, the measurement considered 10 items elements integrating in four constructs; three related to TQM, two related to JIT, three related to Maintenance, and two related to Delivery on time.

The collected information were captured and analyzed in the SPSS 17 software to find measures of central tendency and position, in addition to detect outliers and missing values. To the extreme values for each variable the standardization was done, considering as extreme value an absolute standardized value mayor tan 4 (Kaiser, 2010; Guiaquinta, 2009; Hair et al., 2009). The average variance extracted – AVE was used as an indicator of discriminant validity and convergent validity assessment considering recent studies in supply chain surveys (Avelar et al, 2014; García et al, 2014.). For this case, were evaluated the correlations between variables and was considered a cutoff value of 0.50 as recommended by Kock (2014) and by Green et al. (2014).

After completed the data collection process, 225 questionnaires were considered a representative sample to the study. Table 1 shows the industrial sector and gender of respondents, 156 people were male and only 58 female; 54 people were working in the electronics sector, 39 in medical sector, and 67 in automotive sector; and 11 people did not specify the sector and/or gender. And, in other workforce of respondents were included 50 respondents such as planners and others 24 technicians, 40 were supervisors, and 54 were managers. Only 3 respondents were operation director, 11 people did not answer the questionnaire, and 20 people did not answer about their experience.

Table 1. Demographic characteristics of the respondent firms (n=225)

| Industrial sector | Gender | Total | ||

| Female | Male | Unspecified | ||

| Automotive | 21 | 45 | 1 | 67 |

| Medical | 12 | 24 | 3 | 39 |

| Plastics | 1 | 5 | 0 | 6 |

| Metals | 3 | 3 | 0 | 6 |

| Electronic | 9 | 43 | 2 | 54 |

| Packing | 0 | 2 | 1 | 3 |

| Communications | 1 | 0 | 1 | 2 |

| Services | 1 | 9 | 0 | 10 |

| Others | 9 | 19 | 2 | 30 |

| Consumables | 1 | 6 | 1 | 8 |

| Total | 58 | 156 | 11 | 225 |

In this study, the direction of causality between the constructs and their indicators is originated in a reflexive way, one of the indicators are manifestations of the construct, in a sense that the measurement is determined by the construct itself (Bagozzi, 2007; MacKenzie et al., 2005). When a survey method is used to collect data it is necessary to conduct a statistical technique to evaluate the constructs validity of each construct using convergent and discriminant validity and construct reliability for internal consistency. The analysis of the measurement model fundamentally requires four stages: (1) individual reliability of the indicators; (2) the reliability of the constructs; (3) convergent validity; and (4) discriminant validity.

First, for convergent validity (Hair et al., 2006), were assessed the item loadings. According to the results, all items loaded significantly on their corresponding factors, and their loadings were greater than 0.5 (Chin, 1998), as shown in Table 2. Theses loadings indicate an AVE, which should be greater than the shared variances of each construct. In this case, when the AVE is greater than the squared it is acceptable that each construct relates with greater intensity to its own measures than to those of other variables (Barclay et al., 1995). Also the cross factor loadings are used and the minimum cutoff recommended value is 0.5 for each item, but in addition, the P-value should be significant or low than 0.05 in the construct (Fornell and Larcker, 1981; Kock, 2013), as shown in Table 2.

Table 2. Combined loadings and cross-loadings

| Description | Construct | ||||

| Item | JIT | TQM | Delivery | Maint | P-value |

| JIT46 | 0.867 | 0.149 | 0.170 | -0.047 | <0.001 |

| JIT47 | 0.867 | -0.149 | -0.170 | 0.047 | <0.001 |

| TQM43 | 0.092 | 0.880 | -0.078 | 0.011 | <0.001 |

| TQM44 | -0.179 | 0.859 | 0.120 | 0.003 | <0.001 |

| TQM45 | 0.081 | 0.901 | -0.038 | -0.014 | <0.001 |

| Deliv54 | 0.104 | 0.130 | 0.851 | -0.138 | <0.001 |

| Deliv55 | -0.104 | -0.130 | 0.851 | 0.138 | <0.001 |

| Maint48 | -0.109 | 0.219 | -0.065 | 0.851 | <0.001 |

| Maint49 | -0.114 | -0.023 | 0.016 | 0.915 | <0.001 |

| Maint50 | 0.240 | -0.201 | 0.049 | 0.821 | <0.001 |

Finally, the internal consistency was evaluated by examining the composite reliability of each construct. The composite reliability was calculated using PLS (Kock, 2014). All compositive reliabilities were greater than 0.77, which is above the acceptable level of 0.7 discussed in the literature (García et al., 2014; Autry et al., 2011; Nunnally, 1994). As it was expected, the factors are high in the loading but low in the cross-loadings. It was noted that the P-values are less than 0.05 for the significance test. So, the bold values indicate that those items are integrating in matching variable.

Since it is possible to have collinearity between latent variables, then the variance inflation factor (VIF) is used for detecting it, with the rule that this value should be less than 3.3 in every construct (Cenfetelli and Bassellier, 2009; Hair et al., 2013 Due that the survey was answered on an ordinal scale, the coefficient of Q-squared was used as a nonparametric measure of predictive validity and considering a good validity if its value is greater than zero (Kock, 2013; Hair et al., 2013). The predictive validation in this case (shows in Table 3) is good.

Table 3. Composite reliability and average variance extracted (AVE)

| Coefficients | JIT | TQM | Maint | Delivery |

| R2 | 0.435 | 0.351 | ||

| Composite Reliability | 0.858 | 0.911 | 0.897 | 0.840 |

| Cronbach’s Alpha | 0.670 | 0.854 | 0.827 | 0.618 |

| AVE | 0.752 | 0.774 | 0.745 | 0.724 |

| VIF | 1.910 | 1.930 | 1.686 | 1.501 |

| Q2 | 0.436 | 0.356 |

There are other techniques that have been developed to find and evaluate relations between variables, such as multiple regression analysis, cluster analysis, among others. However, in the case that there are two constructs as independent variables, and two constructs as dependent variables, where these are integrated by others items, the best technique to be used is a Structural Equation Model (SEM) (Williams et al., 2009). This technique is wide and of recent use in causal relation validation in supply chain. Some studies, for example, the work of Green et al. (2014) that analysed the JIT on supply chain performance; García et al. (2014) evaluated the factors to be considered in JIT implementation; other analysed aspects of logistic polices on supply chain performance (Avelar et al., 2014); or the regional infrastructure and services on supply chain performance (Avelar et al., 2014).

Relations between variables shown as hypotheses in Figure 2 were validated in a specialized software WarpPLS 4.0®, that uses algorithms based on Partial Least Squares (PLS), widely recommended for small sample size (Hair et al., 2012). The model was executed by using the WarpPLs3 algorithm, with a bootstrapping resampling method (5,000 resamples) for a better coefficient value convergence and diminish the presence of outliers values. Three model fit indices are evaluated: (1) the average R-squared (ARS), (2) the average path coefficient (APC), and (3) the average variance inflation factor (AVIF), according to literature recommendations (Kock, 2012). For the APC and ARS, the P-values are analysed to determine the efficiency of the model and the maximum cutoff P-value is 0.05. The null hypothesis being tested is that APC and ARS are zero, against the alternative hypothesis that are different from zero.

The direct effects are measured to validate the hypotheses (see Figure 2). These effects indicated a direct relation between the constructs. The indirect effects are measured are given through other variables and occur through two, three, four or more segments. Those indirect effects by different segments give a sum of indirect effects, and that sum of indirect effects and direct effects give the total effect.

Every kind of effect was validated considering the following hypotheses on each parameter values:

H0: i = 0 ( 1 )

H1: i ≠ 0 ( 2 )

According to the results, the proposed model was found empirically significant, the GoF (Good of Fit) =0.542, major to recommended of 0.36 to large GoF (Kock, 2014; Tenenhaus et al., 2005); the APC=0.286,P<0.001; the ARS=0.393, P<0.001 (Chin, 1998), and finally the AVIF=1.663, minor to recommended 3.3 (Kock, 2014).

5.4.1 Direct effects

The statistical significant direct effects can be observed in Figure 2, where the initial proposed model in Figure 1 has been assessed using WarpPLS 4®. For each relationship between constructs in Figure 4 appears a dependence measurement value, which is expressed by β that represents a standardized value, and into parenthesis the p-value for its significance hypothesis test. In this case it is observed that all relationships are significant with p-values minor than 0.01. When exist a relationship that presenting a p-value greater than 0.05, it means that this relationship will include zero in the confidence interval, and thus it is a trivial relationship. Thus, the collected information to assess this relationship is not relevant to explain it. For example, to model in Figure 2 the meaning for values can be interpreted as follows: the relationship between TQM and JIT has a β = 0.431 and P <0.01, which means that when the first variable increases its standard deviation in one unit, the second variable goes up by a proportion of 0.431, and that is its dependency measure. A similar interpretation is made for the other relations among variables. Here it is important to appreciate that the bigger dependence β value occurs between TQM and JIT; this result demonstrates that Total Quality Management program in the process is a very important factor in the results of just in time system within supply chain to improve the company performance.

The dependent variables that are explained from others independents variables have a R2 value, this value variable is a percentage of explained variance that explains a dependent variable, for example the TQM, JIT and Maintenance variables in the model of Figure 2. In this case, the Delivery has a value to R2 of 0.351, which indicates that the 35.1% of its variance is explained by three variables: Total Quality manufacturing (TQM), Just in Time (JIT) and Maintenance (Maint). And therefore, are variables that influence in the supply chain performance. A similar interpretation can be made to the other dependent variables; it is convenient to emphasize that the value for R2 in the Delivery is the major percentage of explained variance of all dependent variables.

Figure 2. Significant direct effects

5.4.2. Indirect effects

The indirect effects in the model are the effects given through other variables that can be two, three, four, or more segments. Therefore, the sum of all of them is the total amount of indirect effects. In Table 4 shows the sum of indirect effect to two segments, this because only exists a performance variable (Delivery). It can be observed that the sum of indirect effects of TQM to Delivery is 0.135, and this value is obtained by multiplying the direct effect of TQM to JIT, with value of 0.431, and the direct effect of JIT to Delivery, with value of 0.314, and so, the result is 0.135. Exists a small difference because the software approximates the values. It can be concluded that the indirect effects in Table 4 are significant with 95% of confidence.

Table 4. Sum of indirect effects between variables

| Variable | JIT | TQM | Maint | Delivery |

| JIT | ||||

| TQM | ||||

| Maint | ||||

| Delivery | 0.135(P<0.001) | 0.096(P=0.008) |

5.4.3 Total Effects

The total effects are the sum of direct and indirect effects obtained among variables. These effects and their p-values are shown in Table 5. It is possible to see that all effects are significant in at least 99% of confidence level. The model presented is based on manufacturing practices as Just in Time, Total Management Quality, Maintenance, and performance in supply chain as Delivery time, these variables present indirect effects on all other subsequent variables. For example, TQM is a variable that has effect on the Delivery that is to say that all the preceding variables have an effect on it (direct or indirect). Thus, one can say that the total effect of TQM on Delivery is 0.330, this is because exists a sum of effect indirect of 0.135 (Table 4), and a direct effect of 0.195 (Figure 2). The sum to these values is 0.330 (0.195+0.135). A similar interpretation can be made for the relationship between the other variables.

Table 5. Total effects between variables

| Variable | JIT | TQM | Maint | Delivery |

| JIT | 0.431(P<0.001) | 0.305(P<0.001) | ||

| TQM | ||||

| Maint | ||||

| Delivery | 0.314(P<0.001) | 0.330(P<0.001) | 0.281(P<0.001) |

This study brings some contributions to supply chain area. First, it is applied structural equation modeling to incorporate the manufacturing aspects in supply chain relationship and integrating different important theories in it. Second, the model is a result that can interpret the relationship and assessing the aspects of Just in Time, Total Quality Management and Maintenance as antecedents to visualize the actual results in delivery elements. All these to know the current real situation of manufacturing practices in maquiladoras of this region. Existing studies that assessing other aspects, and particularly in an international border with United States-Mexico are few which include these variables in maquiladoras companies.

In future researches the goal will be to continue this study including in the questionnaire other aspects of manufacturing practices to evaluate other tools implemented in manufacturing companies. Also, to obtain information from other cities and in different industrial sectors to compare the results of this model would be a good option. Or even, to include other variables of company performance in the supply chain, as for example, aspects of flexibility and agility. This analysis includes the perception of respondents, so it is limited to interpreting the information through the proposed relationships between variables.

Nowadays the JIT is a philosophy worldly known and applied in globalized markets, and it can allows to the firms a still lean in all manufacturing processes, included supply chain management (García et al., 2014). According to the dependency arrows showed in Figure 1, and also the Figure 2, it is possible to perform the following conclusions:

H1: There is enough statistical evidence to declare that Total Quality Management has a direct positive effect on Just in Time system. When the first variable changes by one standard deviation, the second equally does so in 0.431 units directly.

H2: There is enough statistical evidence to express that Maintenance has a direct and positive effect on Just in Time system. When the first variable changes by one standard deviation, the second equally does so in 0.305 units.

H3: There is enough statistical evidence to declare that Just in Time have a direct and positive effect on Delivery time of products. When the first variable changes bye one standard deviation, the second consequently does the same 0.314 units.

H4: There is enough statistical evidence to declare that the Total Quality Management has a direct and positive effect on Delivery time, because when the first variable increases by one its standard deviation, the second one goes up by 0.195 units.

H5: There is enough statistical evidence to declare that Maintenance has a direct and positive effect on Delivery time, because when the first variable changes one standard deviation, the second consequently does so in 0.185 units.

The industrial implications to these conclusions are the followings:

All these implications contribute to the studies in the manufacturing area by the fact that respondents consider: firstly, companies where they work for really use manufacturing practices proposed in the model to achieve better performance in the supply chain, with respect to the timely delivery of finished products; and secondly, the internal supply chain is part of global supply chains, and so companies fit to the supply chain needs by applying other engineering tools and incorporating support departments to manage to integrate both chains.(Mira, pls, si es esto mismo lo que quisiste decir)Aquí no entendí tu duda…

Acknowledgements

The authors fully thank those companies that facilitated our work and the professionals who contributed to this study gently answering the questionnaire. Their information were completely useful to achieve important findings on manufacturing practices implemented and used in this industrial sector.

References

Agus A., Hassan Z. (2011). Enhancing production performance and customer performance trough total quality management (TQM): strategies for competitive advantage, Procedia Social and Behavioral Sciences, 24, 1650-1662.

Ahmad, M.F., Zakuan, N., Jusoh, A., Takala, J. (2012). Relationship of TQM and business performance with mediators of SPC, Lean production and TPM, Procedia Social and Behavioral Sciences, 65, 186-191.

Ahuja, I.P.S., Khamba, J.S. (2008a). Assessment of contributions of successful TPM initiatives towards competitive manufacturing. Journal of Quality in Maintenance Engineering 14 (4), 356–374.

Ahuja, I.P.S., Khamba, J.S. (2008b). Total productive maintenance: literature review and directions. International Journal of Quality & Reliability Management 25 (7), 709–756.

Amasaka, Kakuro, (2014). New JIT, New management technology principle: Surpassing JIT, Procedia Technology, 16, 1135-1145.

Amasaka K. (2008). Strategic QCD studies with affiliated and non-affiliated suppliers utilizing New JIT. Encyclopedia of Networked and Virtual Organizations; III (PU-Z), 1516-1527.

Arumugam, V., Ooi, K.-B., & Fong, T.-C. (2008). TQM practices and quality management performance: An investigation of their relationship using dat a from ISO 9001:2000 firms in Malaysia. The TQM Journal, 20(6), 636-650.

Asociación de Maquiladoras A.C., Index Ciudad Juárez, Available in : http://www.indexjuarez.org/INICIO/presentaciones.html, [Consulted: 1 Sept 2014].

Avelar S., L., García A., J.L., Cedillo C., M.G., Adarme J., W. (2014). Effects of regional infrastructure and offered services in the supply chains performance: Case Ciudad Juarez, Dyna, 81 (186), 208-217.

Avelar S., L., García A., J.L., Vergara V., O.O., Maldonado M., A.A., Alor H., G. (2015). Impact of traditional and international logistic policies in supply chain performance. International Journal of Advanced Manufacturing Technology, 76(5), 915-925.

Babak, J.N., Saeid, I. (2012). Analyzing effective elements in agile supply chain. Management Science Letters, 2(1), 369-378.

Bagozzi, R. P. (2007). On the meaning of formative measurement and how it differs from reflective measurement: Comment on Howell, Breivik, and Wilcox. Psychological Methods, 12(2), 229–237.

Barclay, D.W., Thompson, R., Higgins, C. (1995). The partial least squares (PLS) approach to causal modeling: Personal computer adoption and use an illustration. Technology Studies, 2(2), 285–309.

Besterfield D.H. (1995) Total Quality Management (New Jersey, Prentice Hall).

Bhatnagar, R., Jayaram, J. and Cheng P.Y. (2003). Relative importance of plant location factors: A cross national comparison between Singapure and Malaysia. Journal of Business Logistics, 24(1), 147-170.

Bhatnagar, R. Sohal, A.S. (2005). Supply chain competitiveness: measuring the impact of location factors, uncertainty and manufacturing practices. Technovation, 25(5), 443-456.

Bollen, Kenneth A. (1989), Structural Equations with Latent Variables. New York: John Wiley and Sons.

Breja, S. K., Banwet, D. K., Iyer, K. C. (2011). Quality strategy for transformation: a case study. The TQM Journal, 23(1), 5-20.

Cenfetelli, R, Bassellier, G. (2009). Interpretation of formative measurement in information systems research. MIS Quarterly, 33(4), 689-708.

Chin, W. W. (1998). The partial least squares approach to structural equation modeling. In: G. A. Marcoulides (Ed.), Modern Methods for Business Research (295–358). Mahwah, NJ: Lawrence Erlbaum Associates.

Cua, K.O., McKone-Sweet, K.E., Schroeder, R.G. (2006). Improving performance through an integrated manufacturing program. Quality Management Journal 13 (3), S.45–S.60.

Cronbach, LJ. (1951). Coefficient alpha and the internal structure of tests. Psychometrika, 16(3), 297-334.

Danese, P., Romano, P., Bortolotti, T. (2011). JIT production, JIT supply and performance: investigating the moderating effects, Industrial Management and Data Systems, 112, 441-465.

Demirbag, M., Tatoglu, E., Tekinkus, M., Zaim, S. (2006). An analysis of the relationship between TQM implementation and organizational performance. Journal of Manufacturing Technology Management 17 (6), 829–847.

Enkawa, T., Schvaneveldt, S.J. (2001). Just-in-time, lean production, and complementary paradigms, in Salvendy, G. (Ed.), Handbook of Industrial Engineering, 3rd ed., Wiley, New York, NY, 554-61.

Evans, J.R., Lindsay, W.M. (2005). An Introduction to Six Sigma & Process Improvement, Thompson South Western.

Idris, F. (2011). Total quality management (TQM) and sustainable company performances: examining the relationship in Malaysian firms. International Journal of Business Society, 12, 31-52.

Feng, J., Prajogo, D. I., Tan, K. C., Sohal, A. S. (2006). The impact of TQM practices on performance: A comparative study between Australian and Singaporean organizations. European Journal of Innovation Management, 9(3), 269-278.

Fornell, C, Larcker, DF. (1981). Evaluating structural equation models with unobservable variables and measurement error. Journal of marketing research, 18(1), 39-50.

Foster, S.T., Wallin, C., Ogden, J. (2011). Towards a better understanding of supply chain quality management practices, International Journal of Production Research, 49 (8), 2285–2300.

Fullerton, R. R., & Wempe, W. F. (2009). Lean manufacturing, non-financial performance measures, and financial performance. International Journal of Operations & Production Management, 29(3), 214-240.

Furlan, A., Dal Pont, G., Vinelli, A. (2011). On the complementarity between internal and external just-in-time bundles to build and sustain high performance manufacturing. International Journal of Production Economics, 133(2), 489-95.

García A., J.L., Maldonado M., A.A., Alvarado I., A., Cortes R., G., Alor H., Giner. (2014). A systematic review/survey for JIT implementation: Mexican maquiladoras as case study, Computers in Industry, 65, 761-773.

Giaquinta, M. (2009). Mathematical analysis: An introduction to functions of several variables. New York, NY: Springer.

Green, K.W., Inman, R.A. Birou, L.M. Whitten, D. (2014). Total JIT (T-JIT) and its impact on supply chain competency and organizational performance, International Journal of Production Economics, 147 (Part A), 125–135.

Gunasekaran, A., Lai, K.H., Cheng, T.C.E. (2008). Responsive supply chain: a competitive strategy in a networked economy. Omega: The International Journal of Management Science, 36, 549–564.

Gunday, G., Ulusoy, G., Kilic, K., & Alpkan, L. (2011). Effects of innovation types on firm performance. International Journal of Production Economics, 133(2), 662-676. Elsevier.

Hair, J.F., Anderson, R.E., Tatham, R.L. (1987). Multivariate data analysis. New York, NY: Macmillan.

Hair, J.F., Black, W.C., Babin, B.J., Anderson, R.E. (2009). Multivariate data analysis. Upper Saddle River, NJ: Prentice Hall.

Hair, J., Black, W., Babin, B., Anderson, R., Tatham, R. (2006). Multivariate data analysis (6th ed.). Uppersaddle River, N.J.: Pearson Prentice Hall.

Hair, J.F., Ringle, C.M., Sarstedt, M. (2011). PLS-SEM: indeed a silver bullet. Journal of Marketing Theory and Practice 19 (2), 139–151.

Hair, J.F., Sarstedt, M., Pieper, T.M. Ringle, C.M. (2012). Applications of partial least squares path modeling in management journals: A review of past practices and recommendations for future applications. Long Range Planning, 45(5, 6), 320-340.

Hair, J.F., Hult, G.T.M., Ringle, C.M., Sarstedt, M.A. (2013). Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), Sage, Thousand Oaks.

Hall, R.W. (1987). Attaining Manufacturing Excellence. Dow Jones-Irwin, Homewood, IL. Halley, A., Beaulieu, M., 2009. Mastery of operational competencies in the context of supply chain management. Supply Chain Management, 14 (1), 49–63.

Hansson, J., Backlund, F., Lycke, L. (2003). Managing commitment: increasing the odds for successful implementation of TQM, TPM or RCM. International Journal of Quality and Reliability Management, 20(9), 993-1008.

INEGI (2015): National Statistical Yearbook. National Institute of Statistics, Geography and Informatics.

Jung, J., Wang, Y. (2006), Relationship between total quality management (TQM) and continuous improvement of international project management (CIIPM), Technovation, 26 (5-6), 716-22.

Jun, M., Cai, S., Shin, H. (2006). TQM practice in maquiladora: Antecedents of employee satisfaction and loyalty. Journal of Operations Management, 24(6), 791-812.

Kaiser, H.M. Mathematical programming for agricultural, environmental, and resource economics. Hoboken, NJ: Wiley, (2009).

Kannan, V.R., Tan, K. C. (2005). Just in time, total quality management, and supply chain management: understanding their linkages and impact on business performance, Omega, 33, 153-162.

Kline, RB. (1998). Principles and practice of structural equation modeling. New York, NY: The Guilford Press.

Kock, N. (2012). WarpPLS 3.0 User Manual. ScriptWarp Systems™, Laredo, Texas, USA.

Kock, N. (2013). WarpPLS© 3.0 User Manual. ScriptWarp Systems™. Laredo, Texas, USA.

Kock, N. (2014). WarpPLS© 3.0 User Manual. ScriptWarp Systems™. Laredo, Texas, USA.

Konecny, Philipp A., Thun, Jörn-Henrik, (2011). Do it separately or simultaneously- An empirical analysis of a conjoint implementation of TQM and TPM on plant performance. International Journal of Production Economics, 133, 496-507.

Likert, R. (1932). A Technique for the measurement of attitudes. Archives of Psychology, 22(140), 1-55.

MacKenzie, S.B., Podsakoff, P. M., Jarvis, C.B. (2005). The problem of measurement model misspecification in behavioral and organizational research and some recommended solutions. Journal of Applied Psychology, 90(4), 710–730.

Miyagawa, M., & Yoshida, K. (2010). TQM practices of Japanese-owned manufacturers in the USA and China. International Journal of Quality & Reliability Management, 27(7), 736-755.

Moyano, J., Sacristán, M. (2012). Learning on lean: a review of thinking and research. International Journal Operations Production Management, 32(5), 551-582.

Naylor, B., Nain, M.M., Berry, D. (1999). Leagility: integrating the lean and agile manufacturing paradigms in the total supply chain. International Journal of Production Economics, 62(1–2), 107–118.

Nunnally, J.C. Psychometric theory, 1° edition, McGraw Hill, New York, NY, 1978.

Nunnally, J.C., Bernstein, H. Psychometric theory, 2° Ed., McGraw-Hill Interamericana, México, D.F. (In Spanish), 1985.

Olhager, J., Prajogo, D.I. (2012). The impact of manufacturing and supply chain improvement initiatives: a survey comparing make-to-order and make-tostock firms. Omega 40 (2), 159–165.

Petter, S, Straub, D., Rai, A. (2007). Specifying formative constructs in information systems research. MIS Quarterly, 31(4), 623-656.

Porter, L.,Tanner, S. (2001), Assessing Business Excellence. A Guide to Business Excellence and Self-Assessment. Elsevier Butterworth-Heinemann, Oxford.

Rigdon, E.E. (2011). Rethinking partial least squares path modeling: in praise of simple methods. Long Range Planning, 45(5, 6), 341-358.

Rindfleish, A., Malter, A.J., Ganesan, S., Moorman, C. (2008). Cross-sectional versus longitudinal survey research: concepts, findings, and guidelines. Journal Marketing Research, 45(3), 261-279.

Rodríguez M., R., Sánchez P., D., Martínez F., J.L., Arvizu B., E. (2015). A case study: SMED & JIT methodologies to develop continuous flow of stamped parts into AC disconnect assembly line in Schneider Electric Tlaxcala Plant, IFAC-Papers online, 48(3), 1399-1404.

Schonberger, R. J. (2007). Japanese production management: An evolution with mixed success. Journal of Operations Management, 25(2), 403-419.

Schoenherr, T., Swink, M. (2012). Revisiting the arcs of integration: cross-validation and extensions. Journal of Operations Management, 30, 99–115.

Seth, D., Tripathi, D., 2005. Relationship between TQM and TPM implementation factors and business performance of manufacturing industry in Indian context. International Journal of Quality & Reliability Management, 22 (3), 256–277.

Shah, R., Ward, P.T., 2007. Defining and developing measures of lean production. Journal of Operations Management, 25, 785–805.

Siller P., G., Núñez, P. (2015). Economic report of the maquiladora: BASE Bank economic analysis, INDEX, July 2015, Consulted: Sept 2015, Available http://indexjuarez.org/news/reporte-economico-maquiladoras/

Soin, SS. Critical success factors in supply chain management at high technology companies. University of Southern Queensland, Australia, PhD Thesis, Australia, 2004.

Tenenhaus, M., Esposito Vinzi, V., Chatelin, Y., Lauro, C. (2005). PLS path modeling. Computational Statistics and Data Analysis, 48, 159–205.

Teeravaraprug, J., Kitiwanwong, K., Saetong, N. (2011). Relationship model and supporting activities of JIT, TQM and TPM. Total Quality Management, 33(1), 101 -106.

Topalovic, S. (2015). The implementation of total quality management in order to improve production performance and enhancing the level of customer satisfaction. Procedia Rechnology, 19, 1016-1022.

Valmohammadi, C. (2011). The impact of TQM implementation on the organizational performance of Iranian manufacturing SMEs. The TQM Journal, 23(5), 496–509.

Williams, L., Vandenberg, R. J., Edwards, R. J. (2009). Structural Equation Modeling in Management Research: A guide for improved analysis. The Academy of Management Annals, 3(1), 543-604.

Womack, J.P., Jones, D.T., Roos, D., 1990. The Machine that Changed the World. Rawson Associates, New York, NY.

You have to be 100% sure of the quality of your product to give a money-back guarantee. This describes us perfectly. Make sure that this guarantee is totally transparent.

Read moreEach paper is composed from scratch, according to your instructions. It is then checked by our plagiarism-detection software. There is no gap where plagiarism could squeeze in.

Read moreThanks to our free revisions, there is no way for you to be unsatisfied. We will work on your paper until you are completely happy with the result.

Read moreYour email is safe, as we store it according to international data protection rules. Your bank details are secure, as we use only reliable payment systems.

Read moreBy sending us your money, you buy the service we provide. Check out our terms and conditions if you prefer business talks to be laid out in official language.

Read more