Faculty of Business and Management

INTERNET OF THINGS AS ORIGIN 1-2

INDUSTRIAL INTERNET OF THINGS BASICS 2-3

Related QuestionsMore Answers Below

Ensuring operational reliability

From time-based to condition-based maintenance

Artificial intelligence as means of empowerment

PRECONDITIONS FOR IIOT IMPLEMENTATION 2-3

Business Process Modeling for Industry 4.0 Applications

EVALUATION OF BIG DATA UTILIZATION IN IIOT

COEXISTENCE OF BIG DATA AND IIOT

EXISTING MARKET IIOT SOLUTIONS

CONCLUSION ON IIOT VISION ON THE MARKET

DEVELOPMENT OF THE THEORETICAL MODEL

RELATIONSHIP OF RESULTS TO THE RESEARCH QUESTION

HIGHLIGHT UNEXPECTED AND/OR INTERESTING FINDINGS

PUTTING THE RESULTS INTO THE CONTEXT OF THE RESEARCH AREA

CONCLUSION – SUMMARY – OUTLOOK

The rapid development of the Internet of Things (IoT) has influenced many spheres of the life and now is gaining popularity in a number of industries, as manufacturing, gas and oil, agriculture and more. Industrial IoT (IIoT) as a new trend [1] is attracting a lot of attention from industrial and scientific societies, as it is promising the optimization of asset utilization (e.g. remote management for reducing failures or downtime) and creation of new revenue streams via automation of operational processes. Originally, General Electric [2] described Industrial Internet as a connection of devices over the Internet conducting physics-based analytics, predictive modeling and in general the automation of the manufacturing operations by means of advanced sensors, controls, special software, and support operations available anytime and from any place. However, with the invention of specific solutions and further attempts to develop IIoT idea towards the beginning of the fourth industrial revolution [3], the definition has changed a lot. Reviews from consulting companies and machine-to-machine innovators consider it from different perspectives and, thus lead to misunderstanding of the concept. The following is intended: in some cases, the IIoT means the data that might be obtained as a result of manufacturing processes, integration of the sources and analytics that stands for starting out from data analytics [4]. Others describe a set of sensors installed at the factory facilities, recording the data and transferring it to the information systems that provide workers with necessary information about the process state [5]. This viewpoint mostly describes the work of distributed embedded systems, but let the term “internet” in its initial meaning be missing from the abbreviation. Consequently, this brings up the question of understanding the idea of IIoT, as real application suggested by appearing digital technological startups [6], often differs from the theoretical model of a broader IoT concept.

A high relation between IIoT and Big Data is another important issue. “Sensors embedded in end-points are not much help if the data they generate can’t be collected and transmitted for analysis” – notices the analyst from Moor Insights & Strategy [7]. In point of fact, the already well-established idea of consumer Internet of Things is aimed at improving human life, making it healthy, safe and enjoyable, while the Industrial IoT is associated with delivery of a service and implies utilization by a professional or an enterprise with the original goal to increase productivity and enable maintenance services, energy and design optimization applications, thus it is data-driven.

The research that will be conducted in this paper is intended to clarify the term of IoT and IIoT in general. Additionally, the connection of these terms to Big Data should be addressed, to reveal the applications of Big Data in this concern.

Is Big Data indivisible bundling with IoT or is it just used as a supplement that can improve IIoT? After inducing a general understanding of Internet of Things, Industrial IoT and Big Data in the same context, this paper will show up issues that should be analyzed in detail and be dealt with utter care when IIoT is planned to be implemented in the industry.

The master thesis is devoted to the research of Industrial Internet of Things and especially the usage of information obtained from the connected and sharing data physical objects, including older equipment. Taking into account the industry, the data participating in the IIoT communications often refers to Big Data term due to large volumes, different type and nature and specific requirements for the processing. Thus, the main aim of the present paper is to analyze the enabling of Big Data implication in the Industrial Internet of Things, considering theoretical researches and existing solutions suggested by IoT technologies’ providers.

The main hypothesis implies that there is a strong correlation between Industrial Internet of Things and Big Data, but the ambivalent definition of Industrial Internet and market-speak are causing the appearance of solutions having no connection with both mentioned concepts. The paper will test this hypothesis and

The research questions are the following:

Methodological Approach

Method 1 is literature review conducted with use of scientific papers, companies’ reports and documents from conferences. This method will help to create the detailed definition of IIoT

Method 2 is the content analysis of the modern IoT providers’ solutions aimed at the description of real IIoT application

Method 3 is the analysis of case studies and conducting expert interviews with IIoT solutions providers for assessment of real implication of Big Data and IoT in their products

Method 4 is the creation of the theoretical model summarizing the task description statements

The first part is devoted to explore the concept of IIoT and create the detailed definition of the term, taking into account the viewpoint of different IoT providers. One of the biggest issues here is the research the coexistence of IIoT and Big Data. Taking existing case studies as a basis, the challenge is to set the benefits of the Big Data analytics for companies of various industrial sectors and introduce the special aspects that can be used to identify Big Data in the industry – but not just large amounts of data that are collected.

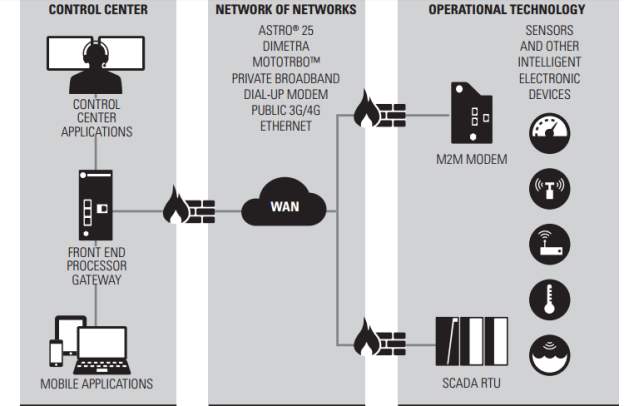

The second part will concretize the previously elaborated IIot aspects, for example to look into the data collecting process and to determine which data should be used in what way. The research will cover issues as data gathering, storing, and processing and the whole IIoT architecture [8], including physical objects, middleware, software applications and human operations. Defining sources, ways of extracting data, its representation and transmitting techniques, the work will be focused on the description of possible use cases of the obtained data in Big Data analytics.

Another task is to conduct marketing analysis aimed at the discovery of IIoT solutions that exist on the market.

Considering the ideas concluded on the previous steps, analysis if companies really provide IIoT and how their solutions deal with Big Data will be conducted. Web-sites from organizations and startups that identify themselves as IIoT providers will be used for this content analysis. To further validate and to additionally refine the outcomes of the analysis interviews with above mentioned IIoT providers will be held, questioning them about their vision of IIoT and Big Data in their products.

In the last part of this paper a theoretical model should be described based on the parts that were elaborated previously, which shows up possible ways of implementing IIoT in combination with Big Data in the fields of industry. This model will help to find answers to for example following questions: what opportunities companies can get from its application, what are the main technical requirements and limits. The model will consider all special characteristics of real Big Data IIoT solutions and conclude the approach that can be used for evaluation of Big Data enabling in Industrial Internet solutions. It will include aspects of devices usage, the architecture of gathering, storage and transferring data and the approaches for conducting the analysis.

This paper may be useful to those who are interested in the current trends in Information Technologies sphere with both technical or business backgrounds, as the conducted research will cover not only engineering components of Industrial Internet of Things but also marketing issues represented by the review of the existing solutions. Although the paper will provide a reader with all necessary explanations and definitions, the audience is desired to possess some background knowledge about IoT and Big Data (at least terms used in these spheres) and business informatics in general. The model created on the last step of the work might be useful for the entrepreneurship that considers implementing IIoT in their business as an approach for choosing the provider and a list of features that the attention should be paid to.

The main research question for this part of the thesis is ‘What is the concrete definition of Industrial Internet of Things?’ Based on the literature review, it is planned to create the detailed definition of IIoT and list the main characteristics of its application. The content analysis will provide with the information on the current state of IIoT and the supplement for its defining based on the real examples via analyzing the approaches of different companies to describing and implementing this idea. To answer this question, firstly the broader term of Internet of Things will be analyzed as a basis of Industrial Internet. Clarifying all necessary features (e.g. the use of sensors), industries of appliance and opportunities for the companies the preconditions for IIoT implementation will be stated. It is expected that the section will cover some issues that imply the foundation for accomplishing the main objective of the thesis.

The Internet of Things is defined by ITU-T Y.2060 [9] as a global network infrastructure for the information society that implies self-configurable options and enables advanced services with use of interconnected physical and virtual things. However, it is needed to look at the definition in more details [10] [11]. The core of the IoT are things (T) that can be represented by devices, machines, buildings, etc. Firstly, they are not networked, have no association with either virtual or physical things and are driven by means of mechanical power or some chemical processes for the performing of their original function. As far as they are equipped with electronic features and software they can become operated by their own algorithms or some external systems. Embedding sensors allow the thing to have a feeling to its environment, so that it can use the conditions of its environment in the decision-making processes and the communication with other components of IoT system. Thus, the things must have the following characteristics:

The last point states for the word Internet (I) in the abbreviation. To have a possibility to bind all the things into a network the different ways of connecting can be used. These are already well-known technologies as Wireless Local Area Network (WLAN), 4G, Global System for Mobile Communications (GSM), Bluetooth as well as Near Field Communication (NFC) [12] that allows high-frequency short-range communication between devices and the lightweight protocol for messaging between sensors and small mobile devices Message Queue Telemetry Transport (MQTT) [13].

Nowadays, the Internet of Things is mostly represented by smart home and car, smart grids and initiatives such as the Cisco Planetary Skin [14], the online platform for the global ecological monitoring.

Smart home concept includes different solutions for intelligent security services and services to optimize the use of household resources, for example Microsoft [15]. Smart cars

• Class fleet management services for individual carriers (some analogue of Uber for freight transport)

• UBI-insurance services

• Maintenance Services for the actual state

3. Commercial and financial services:

• Solutions for the automatic transmission and analysis of data with POS-terminals, including virtual

• Inventory Management households as a service.

Finnaly, it is applied in the industrial segment, changing automatic process control system principles to IoT.

Сегодня Интернет вещей живет и здравствует, чему в немалой степени способствуют такие инициативы как Cisco Planetary Skin, Smart Grid и появление “умных” автомобилей.

1. «Умный дом», включая:

2. «Умный транспорт», включая:

3. Торговля и финансовые услуги:

4. Промышленный сегмент – перевод АСУТП на принципы IoT.

Consumer IoT Systems. These systems connect things that consumers would typically buy directly at a store for their personal use, such as electronics, fitness devices, home automation/security devices, and leisure/entertainment/lifestyle things. Their purpose is to improve lives by making them healthier, safer, or more enjoyable. These applications are what people generally think of when they hear “the IoT.”

Industrial IoT Systems. Here, it’s the connection of things that basically are nonconsumer—the ones typically purchased by a professional or a company in order to use them in the delivery of a service. These include things like industrial machinery; transportation equipment (cars, trains, and planes); health care equipment; and megasystems like smart buildings, smart cities, and smart utility grids. Their purpose is to increase productivity, allow manufacturers to differentiate through the offering of attached services, and reduce environmental impact. Industrial IoT systems enable applications such as predictive maintenance services, energy optimization, and design optimization.

Mechanical hardware that provides structural integrity and keeps everything in place (shown in the green box below).

Electrical hardware, for example microprocessors or microcontrollers, current source, data storage and communications connections (shown in light blue box).

Electromechanical hardware such as sensors, actuators and various output devices that convert electrical energy into mechanical and vice versa (shown in yellow box).

A microcontroller with operating system running an embedded software (shown in the purple box).

The development of networked things is challenging: designers from different areas, who usually use different tools and each contribute a small part to the solution of the main problem, have to work closely together and closely coordinate.

Recently, I’ve met so many people asking about the difference between the Internet of Things and distributed embedded systems that I’ve approached our new CTO and asked him to explain it. Here’s what he replied:

“IoT is primarily a marketing, not an engineering term. When we refer to it in the engineering terms, we normally mean an embedded microprocessor controlled system connected directly or indirectly to the web (e.g., web cameras, smart thermostats, health monitors, etc.).

On the contrary, a typical distributed embedded system such as a commercial building’s lighting or heating system or an enterprise control system is never on the public Internet for obvious IT security reasons. As such, IoT refers to a highly secure and well protected embedded system that’s fully controlled by microprocessors. That’s one of the notions.

Further, IoT is a conceptual framework or an architecture that considers how components (e.g. devices) will communicate with each other (enabling semantic interoperability), i.e. very similar to REST. As such, it’s wrong to call IoT a technology.

So, if your nuclear power plant or a defense system is a closed network that operates in an isolated environment, it’s a distributed embedded system. If it’s open and scalable, homogeneous, reconfigurable, self-configurable and is taking advantage of machine learning, AI and data analytics (sensor based), it is IoT indeed!”

The examples of IoT

Не повторяться с предыдущим параграфом

Выявить точное определение что такое интернет вещей в индустрии, перечислить в каких индустриях, какие обязательные составляющие идустриального интернета

First of all, as some important terms were already listed in this paper for the understanding of Industrial Internet of Things concept it s necessary to define the difference between IIoT, Industry 4.0, M2M and embedded systems. Some

– End-node / Device / Sensor / Thing etc.

– Gateway / Edge / Concentrator / Aggregator

– Cloud

yThe Internet of Things is simply “A network of Internet connected objects able to collect and exchange data.” It is commonly abbreviated as IoT.

The word “Internet of Things” has two main parts; Internet being the backbone of connectivity, and Things meaning objects / devices .

In a simple way to put it, You have “things” (things are nothing but your embedded system devices) that sense and collect data and send it to the internet. This data can be accessible by other “things” too.

Coming to your question, IoT = ET + NT + IT

confused?

At the simplest level, IoT is a combination of Embedded Technology (ET), Network Technology (NT) and Information Technology (IT)..

Let me give you a practical example. Lets imagine you have a “Smart air conditioning unit” in your home that is connected to the internet. (This is a “thing” connected to the internet) Now, imagine it’s a hot summer day and you have left for home from your work. You would like your home to be cool enough by the time you enter it. So, When you leave from your office, you can remotely switch ON the air conditioning unit of your home using your mobile (another “Thing” connected to the internet). Technically, with internet, you can control your AC system from any part of the world as long as both the AC and your mobile are connected using the “Internet”.

A further extension to this concept is: your mobile will command your home A/C that you are leaving the office (it can detect your GPS co-ordinates and decide your are on the move) and depending on the temperature, the A/C will be switched ON by your mobile itself, and the mobile will simply notify you that the A/C is ON.

your Smart A/C will have an embedded system that collects temperature data from a sensor and send it to the cloud (internet) using a wifi module. This is your Embedded system.

The Wifi network and Cloud constitute your Network Technology.

Your mobile will have an APP running in it that will receive the data. Depending on the received data, the app (in turn the mobile) will switch ON the A/C depending on your GPS co-ordinated. The mobile app infrastructure is a simple Information Technology.

So, all you need to do is, add NT & IT infrastructure to your Embedded system to convert it into an IoT system.

1.4k Views · View Upvotes

Richard Williamson, 20 years in Real-Time OS/Middleware/Data integration

Embedded systems are systems designed for limited or no human interaction. IoT is the concept of Things, interacting with Things.

Most IoT Things will also be embedded systems, using the above comparison. Any IoT device that is actually M2M (Machine-to-Machine) is by (the) definition (above) also an embedded system, because it doesn’t have any human interface except maybe a web page from an embedded, lightweight https (hopefully, and not http) server.

On the other hand, an embedded system isn’t necessarily an IoT/M2M device. For example, the JPL Mars missions are embedded systems (using VxWorks from Wind River), but they are not M2M IoT devices because they have a lot of human interaction (albeit from comms distances measured in light-minutes). Even when they use another JPL mission as a comms relay, they are still interacting with humans on Earth, they are not interacting directly with the satellites.

[14]

IIoT is a variant of the IoT which is used in the industrial sector: in manufacturing, agriculture, healthcare, the production of energy and resources. It is one of the most important aspects is the improvement of operational efficiency through intelligent systems and more flexible production techniques.

Numerous industries already use a number of technologies for automation, data exchange and production. The objectives pursued are to improve process transparency, operational efficiency, response times, flexibility in production and ultimately the profitability of companies.

Previously, IIoT technologies were considered to be too risky or too costly for the operational environment, but nowadays the various possibilities of this technology represent the fourth wave of the industrial revolution.

| The Industrial Internet of Things (Industrial IoT) is made up of a multitude of devices connected by communications software. The resulting systems, and even the individual devices that comprise it, can monitor, collect, exchange, analyze, and instantly act on information to intelligently change their behavior or their environment — all without human intervention. | https://www.rti.com/industries/iot-faq.html | |

There are two perspectives on how the Industrial IoT differs from the IoT.

The first perspective is that there are two distinctly separate areas of interest. The Industrial IoT connects critical machines and sensors in high-stakes industries such as aerospace and defense, healthcare and energy. These are systems in which failure often results in life-threatening or other emergency situations. On the other hand, IoT systems tend to be consumer-level devices such as wearable fitness tools, smart home thermometers and automatic pet feeders. They are important and convenient, but breakdowns do not immediately create emergency situations.

The second perspective sees the Industrial IoT as the infrastructure that must be built before IoT applications can be developed. In other words, the IoT, to some extent, depends on the Industrial IoT.

For example, many networked home appliances can be classified as IoT gadgets, such as a refrigerator that can monitor the expiration dates of the milk and eggs it contains, and remotely-programmable home security systems. On the Industrial Internet side, utilities are enabling better load balancing by taking power management decisions down to the neighborhood level. What if they could go all the way down to individual appliances? Suppose users could selectively block power to their devices during high-demand scenarios? Your DVR might power down if it wasn’t recording your favorite show, but your refrigerator would continue to work, resulting in less food spoilage. You could set your washer and dryer to be non-functional, and make an exception with a quick call from your smartphone. Rolling blackouts could be a thing of the past.

Innovators are only beginning to imagine the possibilities that may be achieved by taking advantage of devices and systems that can communicate and act in real time, based on information they exchange amongst themselves. As the Industrial IoT becomes better defined and developed, more impactful IoT applications can and will be created.

More and more people can get on

The knowledge, hardware, and tools needed to develop networked things. This means that intelligent things are offered in ever-increasing numbers and diversity. The popularity of open connection protocols makes it easier to connect things from different vendors to one another and then to enterprise softwares. The systems for data evaluation are becoming more sophisticated and the cloud Creates ideal conditions for high-performance computing systems. This combination makes it possible to extract useful information from the huge amounts of data that these devices generate. Internet of Things, Internet of Things, Industry 4.0, Industrial Internet of Things – where exactly is the difference? So far, we have looked at the IoT systems very generally and have deliberately avoided assigning them to a particular industry. On the Internet, there is a fundamental commonality: networking, sharing data, commands and activating connected services.internet_of_things_june_ovenThe smart oven June wants to revolutionize the networked future from the kitchen. It has been developed with Autodesk Alias and connects to your iPhone or iPad to help you prepare different treats. With kind permission from June. But then the similarities also start already. The differences become clear when we visualize what kind of things we network and what purpose the IoT systems serve. Considering these two aspects, it emerges that there are essentially three major target groups for IoT systems: consumers, industry and production. IoT systems for consumers: Such systems network things that consumers normally buy for their own use in a business Including electrical and fitness equipment, home automation equipment and safety systems, as well as leisure and entertainment. IoT systems for consumers are intended to increase the quality of life by helping to make our lives healthier, safer and more beautiful. Exactly at such applications, we usually think when it comes to the Internet of things.IoT systems in the industry: This is about the networking of things that end consumers do not usually buy. Such systems are usually acquired by professionals or companies and used to provide a service. These include, for example, industrial machinery, transport (cars, trains and airplanes), medical devices and mega-systems such as intelligent buildings, smart cities and intelligent supply networks. In the industry, these systems are intended to increase productivity and enable manufacturers to stand out from the competition through additional services. Another goal is to reduce the environmental impact. Industrial IoT systems are also being developed for preventive maintenance as well as for energy and design optimization. Industrial_internet_of_things_robotsIoT systems for production: This is a subgroup of industrial IoT systems. In this group are classified things involved in production processes in factories (factory buildings, plant engineering, material transport systems, robots, warehouses, etc.). There, production equipment and software are linked to optimize factory workflows in real-time in order to coordinate automatically operated equipment and optimize supply chain and inventory management. In this case one speaks also of the intelligent production or sometimes of intelligent factories. Intelligent factories are also targeting an initiative of the German government, which provides recommendations for the implementation of the industrial project 4.0. Over time, this new technology will continue to expand and it will also be easier to isolate the concept world on the Internet. Until then, much will be discussed, regulated and observed to find out who manages to conquer the upper end of the food chain. Ultimately, however, everything can be traced back to the following conclusion: Everything depends on everything. Editor’s Note: Look at the second contribution by Diego Tamburini, in which he examines the link between data and devices and their added value for consumers .

Machine learning means providing computers with the ability to learn from the inputs they have received. It could be described as enabling computers to predict patterns based on previous patterns, without having been explicitly programmed to do so. A computer receives inputs, learns which factors in the data are relevant when it comes to making predictions, and uses those learnings to improve its predictions about the influence of certain aspects.

“For example, a car battery running hot when driving at high speed is expected, but a hot battery hours after operating implies a short circuit. Machine learning enables the machine to determine which factors matter in different circumstances, and predict the outcome,” Jagers explains.

Fundamentally, machine learning helps detect anomalies. Another good example is the vibration analysis for wind turbines: Heavy vibration in a windy weather is a precondition, but when there is no wind, detecting heavy vibration is most likely a sign of an issue that needs to be addressed. In this case, there are only two factors that need to be considered. Nevertheless, with machine learning, up to thousands of factors and dimensions of data can be used to build predictions.

Having the ability to spot anomalies at an early stage of a given process helps companies to focus on delivering operational reliability to their customers and users.

“Think of a modern rail transport system. If one railroad switch fails, it is not just one train that will not be able to pass it. A seemingly small error can cause severe problems and major delays in the entire network, which in addition can result in a lot of negative publicity and such”, Jagers says.

In complex process industries, such as food production, impacts of a single failure in the system can reach both ends of the value chain. He continues: “A delay in the product distribution can lead to a lot of the so-called raw material, such as meat, going to waste, which of course is not only financially but also ethically and morally unacceptable. At the same time, failing to deliver on time has consequences on the retailers and their customers too. It is the reliability that matters – if one thing goes wrong, there are tons of other things that go wrong too.”

Machine learning does not only help prevent possible problems from occurring. It can also help optimize and streamline processes in the sense that it saves manufacturers and service providers from having to carry out certain procedures just in case. Equipment downtime is costly, so when it comes to maintenance, many want to be on the safe side.

“It is very hard to predict the exact time and reason for an equipment failure. On top of that, there is often a decreasing number of qualified maintenance technicians available. This often means having to increase efficiency when it comes to determining equipment’s need for repair and maintenance. In addition to helping detect anomalous functions in a particular equipment, machine learning can be utilized to create a list of all the pieces of equipment that need maintenance in a given facility, why they need it and when will they need it,” Jagers describes.

Having this kind of detailed information enables transferring from time-based to condition-based maintenance. “A lot of repair procedures are carried out before they are actually required. With condition-based maintenance, equipment is repaired exactly when needed, which brings more reliability, efficiency and cost-savings,” Jagers concludes.

Machine learning is an important driver in shifting towards pay-per-use models, where manufacturers focus on delivering operational reliability instead of pieces of equipment. Jagers, however, brings up a broader perspective on artificial intelligence and its impact on our future.

He sees computers as tools that can empower people to make better decisions and therefore become more productive: “I firmly believe that no matter how much artificial intelligence develops, computers can never fully replace human workers,” he ponders.

“Nevertheless, what they can do, is increase the overall productivity of the workforce by being capable of processing vast amounts of data and drawing conclusions from it. And that is really the most valuable advantage, because learning to do more with less is actually the only way of increasing prosperity in the world,” he summarizes.

In an IIoT system, many different new Information and Communication Technologies (ICTs), such as Industrial Wireless Networks (IWN) and Internet of Things (IoT) [16], [17] are incorporated into a single system. Similarly, in this prototype platform, some new ICTs are introduced. The architecture consists of four components: machines and equipment, networks, the cloud and terminals. Obviously, as shown in Figure 1, the prototype system is a closed loop for producing specific and personalized products to meet the users’ needs and desires. First of all, the users design the products according to their preference or provide the key parameters for personalized products through web pages. Then, the web server submits the user information to the industrial cloud, which parses the product data and the key parameters. Meanwhile, these optimization producing data are transmitted to industrial robots, workmen, and controllers of conveyor belts via wired or wireless networks. The production system begins to create the products depending on these data. During the manufacturing process of the product, all kinds of related data are transmitted to the cloud and neighboring nod

es for management and optimization.

On one hand, the plan not only provides the necessary information for managing and monitoring production, but also allows the optimization of processes and procedures for ensuring higher quality and increasing the production efficiency. On the other hand, the user can amend the design according to the manufacturing data. In the same way as before, these modifications and re-optimizations are delivered via all kinds of wired or wireless networks after being processed by the industrial cloud.

The physical layer is the basic component, and directly determines the specific type implementation and production. Meanwhile, from a functional perspective, it is responsible for the specific physical activities, such as manufacturing, transportation, mobility, logistics, and obtaining sensor or other data. In this platform, all kinds of devices, such as AGVs (Automated Guided Vehicles), manipulators, flexible conveyor systems, manufacturing equipment, warehouses, and sensors, may compose the physical layer. The following setup illustrates the working processes of the physical layer in this platform.

After obtaining the working instructions from the industrial cloud, the AGV first begins to carry the raw products with RFID tags from the warehouse to the entrance of a flexible conveyor system. The RFID tags include the key manufacturing information and the data of producing progress. Then, the raw products are transported to the corresponding manipulators, where machines and workmen prepare them for the ensuing processing. After that, the products are transported to the output exit by the conveyor belts, and the AGVs carry the finished products to the warehouse. During the loop, all the sensors have the ability to record the key parameters necessary for monitoring and alerting, and save the product’s information during the whole processing.

Actually, for the smart factories of Industry 4.0, it is widely understood that wired or wireless networks must permeate the platform for transmitting data, commands and other information between the cloud and the equipment, including both machines and products. In all cases, networks play an important role in the implementation of Industry 4.0. In other words, networks play a role similar to the human body’s nervous system. In a similar manner, in the prototype framework of Industry 4.0, several network technologies are used to support the platform. The networks are formed by inter-factory networks, including IWNs, industrial Ethernet, NFC (Near Field Communication) utilizing RFIDs, MCNs (Mobile communication networks), civilian internet, etc.

From an intra-factory aspect, there are several types of data transmission taking place. Firstly, in order to determine and verify the location of products, RFID tags are mounted on the products. The RFID tags are used to read or write information about the products. Then, the RFID Gateway (e.g. a Raspberry Pi with Linux OS) transmits the product data using wireless protocols, in this case using a USB-WiFi module (IEEE 802.11), to send the related information to the equipment and to the cloud via access points (e.g., MOXA-AWK-3121). Secondly, in this system we provide wireless communications capabilities on equipment, such as the manufacturing machines and AGVs using technologies, such com-Wi-Fi (e.g., MOXA-Nport-W2150A) or wired-Wi-Fi (e.g., MOXA-AWK-1121). Then, the equipment can communicate with other equipment, the cloud, and the products via wireless networks because of the ease of access to civilian networks, such as the internet.

Outside the factory, there are two ways of dealing with the problem of communicating with users and management. A wired network is the best option for complicated technologies such as the internet. In the platform, we use Ethernet for connecting to users and inter-factory networks. With the development of mobile communications, especially 4G and 5G, mobile networks are becoming more widespread, so in order to provide easy access to this system for the users and the management, some mobile communication technologies can be introduced into the networks.

Based on the above discussion, it is evident that the cloud layer plays an important role in Industry 4.0, since the cloud not only performs computing for the optimization algorithms and decision making, but also stores massive data [18], [19]. Specifically, in this platform, the cloud is responsible for resolving the users’ needs for products, optimizing the flexible conveyor system, fusing and storing data, and even simple data mining operations.

The prototype platform consists of hardware and software. Five servers are used to construct the cloud. The machines were identical models NF8480M3 of Inspur Cor. with 8GB memory, a hard disk capacity of 500GB and 16 CPU cores each. The cloud setup used Citrix XenServer 6.5 and Apache Hadoop. The latter is a software library which acts as a framework that allows for the distributed processing of large data sets across clusters of computers using simple programming models. For storing data from the equipment, and the users, a MySQL database system was adopted in the platform.

The intelligent terminals are directly used to display the related information and key data using web pages, messaging applications or emails. They can provide an effective, specialized, and visual way for users, workmen, and management to interact with the system. Large LCD screens, smart phones and PCs compose the terminal layers. Furthermore, the content’s structure can be adapted according to different aims, goals and classes.

Using user web page as an example, the terminals can be divided into two kinds of functions: reservation of resources and monitoring of the production process. In the reservation page, users can provide key parameters according to their needs by choosing some different options or submit designs. Meanwhile, taking the words too literally, reloading web page displays can provide updated information about the products, such as procuring progress, quality, and logistics.

As mentioned above, all kinds of status data (e.g., equipment status data, product data, and measurement and control data) can be gathered by wired or wireless sensor nodes and forwarded to the industrial cloud platform. After analysis, macro-control of the devices may be realized in order to harmonize the different kinds of devices. In summation, the information exchange can be divided into three kinds: information exchange among physical layer devices, information exchange between physical layer devices and IWNs, and data processing in cloud and interaction through mobile terminals. Figure 2 shows the information exchange occurring in an industrial environment.

Перечисляю вновь индустрии, где можно применить

Далее по конкретным индустриям объясняю, как там можно использовать или уже используется ииот

Вывожу итог – диаграмму в чем плюсы и минусы от внедрения.

Industry 4.0 is part of the high-tech strategy of the German Federal Ministry for Education and Research [1], [2]. The term Industry 4.0 derived from the 4th industrial revolution and is a technology-oriented concept mainly for the manufacturing domain but can be interpreted more generally and applied to any value chain organization.

The 4th industrial revolution means a paradigm shift in industry: The first industrial revolution brought the mechanization of production, the second industrial revolution was about mass production and the third industrial revolution means the digitization (electronic component, computer and IT. Industry 4.0 enables suppliers and manufacturers to leverage new technological concepts like CPS (Cyber-Physical Systems), Internet of Things and Cloud Computing (CC): New or enhanced products and services can be created, cost can be reduced and productivity can be increased [3].

In the discussions about Industry 4.0 the term Smart Factory [4] is mentioned quite often and even if the word smart might be open to debate, the main point is clear: The idea is to create a network with decentralized decisions and technological components with enhanced capabilities that can interact with each other and with human in real time. The components are (semi-) autonomous and can be equipped with advanced computing power or AI (Artificial Intelligence).

Industry 4.0 comprises the following terms or technological concepts:

Important topics like Big Data and Business Intelligence are also part of Industry 4.0, but in order not to go beyond the scope of this short introduction, the concepts mentioned above are considered sufficient for the understanding of the idea of Industry 4.0.

The terms Internet of Things (IoT) and Cloud Computing (CC) imply a technology-oriented standpoint, e.g. devices and other electronic things play an active role in an environment and usage context that is connected (to the Internet). But when it comes to application scenarios, a sole technology-centric approach could be counterproductive: IoT devices are not used for their own sake; they must contribute to a more effective or a more efficient business process or a better user experience.

SECTION II.

Business process models (BPM) describe behavioral aspects of a system and are usually on the formal requirements or early design level. All major architectural and methodological frameworks include process modeling: TOGAF with the architecture domains (e.g. Business Architecture) and the ADM (Architecture Development Method) [7], RM-ODP (Reference Model of Open Distributed Processing) with its Enterprise and Computational Viewpoint [8], [9], and the FEAF (Federal Enterprise Architecture Framework) with its Business Reference Model [10]. In terms of OMG’s MDA (Model Driven Architecture) BPM is a PIM (Platform Independent Model) concerning the design and implementation platforms [11].

The notation language in this context is the OMG Business Process Model and Notation (BPMN 2.0) [12] with its modeling elements like tasks (service, send, receive etc.), events and data objects. Language extensions for aspects of Industry 4.0 application are needed, e.g. IoT-aware process models (IoT-A, Internet of Things Architecture [13], [14]). Existing extensions described in [13] and [15] are used and also a new extension (for Cloud App) are presented here. This BPMN-based language is called Industry 4.0 Process Modeling Language (I4PML): The following table shows the extensions as icons.

[15] [5] [16]

Сенсоры бываю такие и такие

To learn more about sensors and IIoT, see some of our favorite readings including:

The Industrial Internet of Things being closely connected to the IoT is a

The section is devoted to answer a research question “How is Big Data linked to IIoT and what are its possible implications?” as well as issues of data collecting/storing/processing, the characteristics of big data and the current state of its appliance in terms of IIoT.

Big data technologies create a lot of new opportunities and benefits for the industrial sector and at the same time they lead to great changes in the industry and cause the digital transformation.

Когда мы говорим о индустриальном интернете, то the data generated by industrial equipment “has a higher potential value than other types of big data” that we are used to for example different sources of consumer data.

Through predictive analytics, the ability to track the state of the infrastructure components IIOT significantly reduces costs on maintenance. According to the Accenture report [4] preventive maintenance reduces scheduled repairs by 12 percent, and thus costs on maintenance by 30 percent preventing 70 percent of shutdowns.

[4]

Sensorfusion,

Нужно выделить те области, где ииот

После этого здесь для разных сфер выписываем возможные ресурсы, можно нарисовать картинку, главное – учесть то, что не только сенсоры но и прочие каналы, написать про эмбедед системс и сайберсистемс

http://cdn.iotwf.com/resources/71/IoT_Reference_Model_White_Paper_June_4_2014.pdf

после того как есть ресурсы, пишем о том, как с них берутся данные, про сети передачи данных, про то о каких объемах речь и как они хранятся, особый уклон на неструктур в конце

http://cdn.iotwf.com/resources/71/IoT_Reference_Model_White_Paper_June_4_2014.pdf

CLASSES OF IIOT SEVICE

пишем, что такое биг дата после чего примеры того, Как такие данве берутся из индестрии.

This part will consider the existing IIoT solutions that can be divided into two cathegories. First one is listing the solutions of big well known companies without taking into account their reports where the detailed information can not be acquitted. The second set of companies includes startups that appeared for several past years and call themselves as IIoT providers.

The Table 1 shows the information about the companies that work with IIoT solutions describing the kind of service they provide. Considering the classes of IIoT services

Table 1

| GE | |||

| AMAZON | |||

| ACCENTURE | |||

| SAP | |||

| IBM | |||

| MICROSOFT | |||

| ORACLE | |||

Классы сервисов иот по рребованиям [19]

Кждая компонента влияет на сервис

Сервис = ф(задержкаЮ частота обновления, аналитика и тд)

Response Time, Availability, Security, Analytics, Application Enablement, Connectivity, Edge Devices and Networks, Continuity

Continuity Continuity ensures that the service is available for certain amount of time without any interruptions. Furthermore if there is an incident, continuity allows to restart the service and regain access to data and functionality of the service within particular time frame. 2 Quality (of service) Quality describes attributes of service offering like access time, Availability Continuity Incident management Security Quality Monitoring Security Functionality Data access Security Service availability (in the clouds) Page 6 of 16 number of supported users, amount of data processed in a way that is convenient for the user for example without any lags or timeouts. 3 Functionality Functionality describes what end user can do and achieve in a particular time frame using selected services. 4 Incident management Incident management deals with incidents concerning services used by the end user. In case of any disruption of any above components the end user should be notified. 5 Monitoring In order to assure proper availability levels both the service owner and the service end user should be able to monitor it. It means that continuity, quality, functionality and security components should be measured and checked constantly. 6 Data access We can’t speak about availability if we forget the data either entered by the end user or data generated by the service based on end user data. Basically all the data end user enters and process including all results of this process should be available on-demand by the end user. 7 Security Obviously security is tightly connected with availability and its components like incident management, monitoring and data access. The end user expects that all those processes are in place and are working correctly. Furthermore as part of data access he expects his data to be secure i.e. no unauthorized access to his data is possible.

https://secure.in.gov/iot/files/Service_Level_Agreement_-_FY15.pdf

The Services Platform must surpass vertical solutions by integrating all essential technologies and required components into a common, open, and multi-application environment. The functions of the IoT Services Platform include the ability to deploy, configure, troubleshoot, secure, manage, and monitor IoT devices. They also include the ability to manage applications in terms of software/firmware installation, patching, starting/stopping, debugging, and monitoring. The Services Platform also provides capabilities that simplify application development through a core set of common application services that include data management, temporary caching, permanent storage, data normalization, policy-based access control, and exposure. In addition to these, the Services Platform is expected to offer some advanced application services, which include support for business rules, complex event processing, data analytics, and closed loop control. Figure 7.1 shows examples of key IoT Services Platform functions. A more detailed and structured list will be provided in Sects. 7.2–7.12. As can be seen from the list in Fig. 7.1, many of the capabilities of the IoT Services Platform represent what can be loosely categorized as “management functions.” These, however, are different from traditional network management. Traditional network-level management functions were originally defined, in the early 1980s, by the Open Systems Interconnection—Systems Management Overview (OSI-SMO) standard as FACPS: fault, configuration, accounting,

Traditional Management • Fault Management & Troubleshooting • Configuring & Deploying • Accounting & Billing • Performance Monitoring • Security Management Application Management • Software/firmware installation • Patching • Starting/stopping • Debugging • Monitoring Application Development • Data Management • Temporary Caching • Permanent Storage • Data Normalization, • Policy-based Access Control & Exposure Application Services • Business Rule Support • Complex Event Processing • Data Analytics • Closed Loop Control. • Subscriptions & Notifications • Service Discovery Fig. 7.1 Examples of key IoT Services Platform functions

performance, and security. A decade later, the Telecommunications Management Network (TMN) of ITU-T advanced the FCAPS functions as part of the TMN recommendation on management functions. The term FCAPS is often used in network management books as a useful way to break down the multipart network management functions. While FCAPS still apply, the overall management functions of IoT solutions are more multifaceted than traditional networks. This is due to the following factors: • IoT solutions include new devices (e.g., sensors, white-label gateways, and white-label switches). Some of these devices are inexpensive and generally lack the type or level of instrumentation required for traditional management functions. • IoT solutions utilize relatively recent technologies (e.g., tracking exact location of IoT device using GPS triangulation) that were not considered by traditional management solutions. • IoT solutions support more than two dozen access protocols (as was mentioned in Chaps. 4–5). The network management for each protocol may vary. • IoT solutions support multiple verticals, each of which has different sets of management, quality of service, and grade of service requirements. • IoT solutions utilize a new fog layer with new and challenging network, compute, and storage management requirements. • Finally, many enterprises and service providers are expected to outsource and, in many cases, multisource key parts of the network and/or management functions. This requires additional, mostly new, capabilities such as secure integration that spans connecting workflows between multiple service providers. This chapter describes the essential functions of the IoT Services Platform (Fig. 7.2). It focuses on identifying key capabilities with minimum emphasis on the relationship between the functions or their access protocol interfaces. Such relationship and protocols were addressed in the IoT Protocol Stack Chaps. 4 and 5.

Research Question 1 is devoted to defining terms IoT, IIoT, analyze the approaches of different companies to describing and implementing this idea and show the importance of IIoT in the modern world.

Research Question 2 will clarify the connection between Industrial Internet of Things and the term Big Data, including data gathering, storing, and processing techniques and describe the main components of the IIoT architecture when it works with Big Data.

Research Question 3, by mapping the definition of IIoT to cases of real applications in the industry, is expected to reveal that an amount of companies in the fields of industry abuse the term Big Data and IIoT by using them wrong. The research of the existing so-called IIoT solutions and expert interviews will help to conclude how companies understand the features of this concept and if they provide products that have necessary characteristics to be called IIoT and Big Data at the same time. In addition, the theoretical model will be created to show possible ways of implementing IIoT with Big Data in the industry, including issues of devices usage, gathering, storage and transferring data and the approaches for conducting the analysis.

Overview Research questions – methods – expected results

| Research questions/ hypotheses | Method(s) per research question | Expected result(s) per method |

| What is the concrete definition of Industrial Internet of Things? |

You have to be 100% sure of the quality of your product to give a money-back guarantee. This describes us perfectly. Make sure that this guarantee is totally transparent.

Read moreEach paper is composed from scratch, according to your instructions. It is then checked by our plagiarism-detection software. There is no gap where plagiarism could squeeze in.

Read moreThanks to our free revisions, there is no way for you to be unsatisfied. We will work on your paper until you are completely happy with the result.

Read moreYour email is safe, as we store it according to international data protection rules. Your bank details are secure, as we use only reliable payment systems.

Read moreBy sending us your money, you buy the service we provide. Check out our terms and conditions if you prefer business talks to be laid out in official language.

Read more