With the highly demand on oil and gas as a source of energy, operators are anxious to find petroleum resources even if it requires drilling a challenging wells, such as drilling to reach shale formations by using hydraulic fracturing process. The process of hydraulic fracturing gives great quantity of hydrocarbons but it involve many potential impacts on the environment. in order to reduce and avoid the risks and impacts of hydraulic fracturing on the environment, developing EMS plan would be crucial. Environmental Management System (EMS) is defined as a series of processes and practices that support an organization to decrease its environmental impacts and increase its operating efficiency. An EMS system depends on several stages that need to be followed.

(EMS)

In this report the reader is expected to understand the EMS system and how we can build a whole new system for Kuwait oil companies focusing on the reduction of the effect of hydraulic fracturing process. this research covers the hydraulic activity and it is environmental impact and it is subdivided into three major areas :

History of Hydraulic Fracture

Hydraulic fracturing began as an experiment in 1947, and the first commercially successful application followed in 1950. As of 2012, 2.5 million “frac jobs” had been performed worldwide on oil and gas wells; over one million of those within the U.S. Such treatment is generally necessary to achieve adequate flow rates in shale gas, tight gas, tight oil, and coal seam gas wells. Some hydraulic fractures can form naturally in certain veins or dikes.

The development of science & technology has led to discover a new technique in oil & gas industry called Hydraulic Fracturing. This method is used to stimulate shallow, hard rock oil wells at the beginning of 1860s. However, dynamite or nitroglycerin detonations were used to increase oil and natural gas production from petroleum bearing formations. On 1865, Edward A. L. Roberts received a patent for an “exploding torpedo” where he uses liquid and solidified nitroglycerin that applied to water and gas wells. Stimulation of wells with acid, instead of explosive fluids, was introduced in the 1930s. Due to acid etching, fractures would not close completely resulting in further productivity increase.

“Acid fracturing”. Society of Petroleum Engineers. Retrieved 12 October 2014.

In 1997, Nick Steinsberger, an engineer of Mitchell Energy applied the slickwater fracturing technique, using more water and higher pump pressure than previous fracturing techniques, which was used in East Texas by Union Pacific Resources in the Barnett Shale of north Texas. In 1998, the new technique proved to be successful when the first 90 days gas production from the well-called S.H. Griffin No. 3 exceeded production of any of the company’s previous wells.

Robbins, Kalyani (2013). “Awakening the Slumbering Giant: How Horizontal Drilling Technology Brought the Endangered Species Act to Bear on Hydraulic Fracturing” (PDF). Case Western Reserve Law Review. 63 (4). Archived from the original (PDF) on 2014-03-26. Retrieved 2016-09-18.

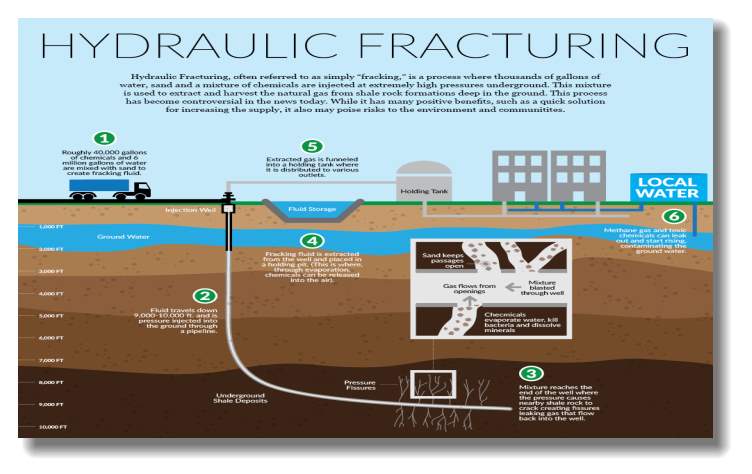

It also called fracking: describes the recovery of natural gas from deep layers inside the earth, porous rock is fractured by the use of water, sand and chemicals in order to release the enclosed natural gas. In addition, almost 60% of all new oil and gas wells are drilled by using hydraulic fracking. Fluid used contains mainly water, sand, and chemicals.

On average:

Process:

First, a shaft is drilled several hundred meters into the earth. From there, a horizontal hole is drilled into the gas-bearing layer of rock. Next, the fracking fluid pumped into the ground using high-performance pumps. The mixture penetrates into the rock layer and produces innumerable tiny cracks. The sand prevents the cracks from closing again. Next, the majority of the fracking fluid is pumped out again, and now the natural gas can be recovered. As a rule, the fracking fluid is pumped back into deep underground layers and sealed in there.

Environmental Impacts of Hydraulic Fracturing. (2012). Retrieved from Exploration and Exploitation of Unconventional Natural Gas Deposits: https://www.umweltbundesamt.de/sites/default/files/medien/461/publikationen/4346-1.pdf

Since the discovery of oil in1859 until now it has formed world’s major commercial source of energy. In 1968, Due to the depletion of well sources, geologist went to new discovery to extract oil and gas horizontally by fracking tight shale formation to create a path for hydrocarbons and this was called hydraulic fracturing.

Hydraulic fracturing is a process of oil and natural gas extraction.Where companies drill wells thousands of feet deep into the shale rock formations underground. These wells are cased with steel pipes and then a solution of water, sand and chemicals is pumped into these wells under high pressure. This process creates cracks within the shale to allow oil and natural gas to be released into these wells and pumped to the surface through the wellhead. However, in order to extract these trapped substantial deposits many environmental impacts are associated

http://sites.nicholas.duke.edu/avnervengosh/files/2011/08/Quantity-and-source-of-unconventional-wastewater.pdf

http://blogs.nicholas.duke.edu/thegreengrok/frackingwater/

The EMSH Company stands for the Hydraulic Management System for Hydraulic Fracturing. The company has built for a specific aim, which is eliminating the side effects and impacts of the hydraulic fracturing processes that is used now days. This company is implemented in Kuwait. This company is build based on the ISO 14000 standards. It is the company duties to conserve our earth from any harmful activities such as the hydraulic fracturing process.

This company was established in 22/1/2017 by partnership of four members. The members are Batool pour shamsi, Kawther AlQattan , Dana Ali and Sara AlQallaf. The decision to build this company has been taken between us. Since we are petroleum engineers so we are focusing on hydraulic fracturing process, it is widely used in extracting oil from different reservoirs.

(Brief introduction to EMS requirements)

The purpose of the environmental policy is to have regulations that will control the impacts of the environmental aspects that are generated from the hydraulic fracturing process, therefore, will improve of the company’s ability to manage and account for environmental problems and hazards.(1)

(1)http://media.metro.net/about_us/sustainability/images/Environmental.pdf

Within this scope we are dedicated to follow opportunities to reduce the effects of hydraulic fracturing by making some adjustment to the chemicals that are used and apply healthy techniques to the environment based on the company’s regulations and policy, to avoid waste and to observe with all environmental regulation in order to protect the environment. (2)

The purpose for this requirement is to identify the related environmental aspects which is associated with the effect of Hydraulic Fracturing on the environment, and identify the most significant aspects and impacts due to their hazardous effect.

The related activities and facilities of the significant environmental aspects need to be determined in order to improve the company’s activities.

Part of any organization or activity that is relate to the environment.

Resulting effects are either good or bad from the aspect.

Identification of environmental aspects and impacts:

First of all in order to identify the environmental aspect few steps should be followed to determine these aspects:

Hydraulic fracturing as a modern technique has a very good results on enhancing oil production rates, on other hand, its impact on the environment can not be neglected as it effect the whole ecosystem is obvious where this result from the following aspects : Chemicals, proppants, sand, fire gun, flow back water, noise and well logging (gas radiation).

| IMPACT |

You have to be 100% sure of the quality of your product to give a money-back guarantee. This describes us perfectly. Make sure that this guarantee is totally transparent.

Read moreEach paper is composed from scratch, according to your instructions. It is then checked by our plagiarism-detection software. There is no gap where plagiarism could squeeze in.

Read moreThanks to our free revisions, there is no way for you to be unsatisfied. We will work on your paper until you are completely happy with the result.

Read moreYour email is safe, as we store it according to international data protection rules. Your bank details are secure, as we use only reliable payment systems.

Read moreBy sending us your money, you buy the service we provide. Check out our terms and conditions if you prefer business talks to be laid out in official language.

Read more