Abstract

Houses in the UK appear to have significant increase in house energy efficiency as observed by the Standard Assessment Procedure (SAP), the last 10 years.

The aim of the project is to study possible features a house should have to be called ‘energy efficient’, emphasizing the need of using cleaner forms of electricity in households as well as in life in general. To achieve that, different factors which form an energy efficient house are being examined.

As research has proved, K-glass reflects less visible light and absorbs low percentage of heat from sunlight, whereas TEC7 glass transmits a high percentage of light .

Comparing their mechanical, electrical and optical properties, one should be able to choose which of them should be used for a specific application.

Conclusions show the most energy efficient type for double glazing window is low emissivity glass (low-E). K-glass is a indeed a low emissivity coated glass.

These findings have significant implications first of all for the effect of everyday life on the planet and secondly for the savings that long term use of renewable energy could have on the monthly bills.

Chapter 2 | Theory and Literature Review

2.3 | Properties of tin oxide thin films

2.4 | Uses of thin films in the intelligent house

2.4.1 | Low – Emissivity windows (in Buildings)

2.4.2 | Amorphous silicon (Solar Cells)

2.4.3. | Copper indium gallium diselenide (CIGS) (Solar Cells)

2.4.5 | Cadmium telluride (CdTe) solar cells

Chapter 3 | Review and Development

3.1 | The future of thin films – New applications

3.1.1 | Perovskite Solar Cells

3.1.2 | Oxide thin-film transistor for wearable display

3.1.3 | ‘’Passive Cooling’’ in Buildings

3.1.4 | Tarnish-proof films for flexible displays, touch screens

3.1.5 | Control oxygen for electronic properties

Chapter 4 | Results and Analysis

4.1 | The future intelligent house

4.2.2 | Renewable sources of energy

Chapter 5 | Discussion and Conclusions

This dissertation has a central focus on thin films, a constantly growing material in the field of Applied Physics.

The aim of the project is to introduce the concept of the ‘intelligent house’ and highlight the use of oxide thin films in the modern house.

Firstly, it explains what one means by ‘thin films’ what properties do thin films have, alienated by their nature. Additionally, it presents their vital role in the intelligent house, pointing out the main areas that they are used in.

The project emphasises in the need of changing our behaviour towards environment in order for the disasters happening in the 21st century such as the climate change and the atmospheric pollution to eliminate.

Those are the main reasons which lead to the further study of renewable energy and by extension the study of ‘thin films’.

Energy from the sun, the rain and the wind all exist in abundance in planet Earth and are being renewed constantly thus could be called ‘renewable’.

Taking these from the Earth, they could be converted into thermal and electrical energy to serve the needs of modern life.

The development part of the project contains information on recent and future applications of thin films, not only on buildings, but generally in the science field.

The final part comes to put together all of the above, in a Chapter that outlines the properties of the future intelligent house, given the need of a sustainable future world.

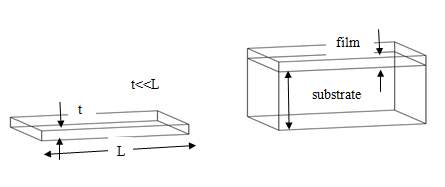

Defining thin films one would say, a thin film is a microscopically thin layer of material which is being deposited onto another. The ‘base’ material could be metal, ceramic, semiconductor material or even plastic (Shazly et al,1998). One dimension, usually thickness, must be much smaller than the other two (fig.1). That, also applies for the substrate i.e. the film thickness is much smaller that the dimensions of the substrate (fig.2) (Nix, 2005)

Depending on the base material thin films are considered to be conductive or dielectric (ibid).

Fig.1 Fig. 2

Plain thin film geometry Thin film on substrate geometry

In this project, two of the main applications of thin films are going to be examined; thin films used in window glazing and thin films used for solar cells.

The difference in the structure of them is the factor which changes their function.

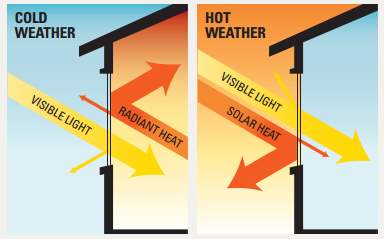

Low emissivity windows transmit most visible light and block infrared radiation i.e. heat (fig.3) (Rissman&Kennan,2014)

Thin films are placed on windows as coating, as a result the reduction of heat transfer and reflection of heat from indoors back in. (Pilington, 2017)

Window glass itself might be coated in order to provide low emissivity characteristics, however that is not the ideal case since such a coating has many disadvantages, most importantly does not provide protection to ultraviolet radiation (Nian Yang, 2000). To overcome those difficulties, Yang and his team, introduced the idea of solar control films which is basically a substrate placed on glass and then another film laminated on the substrate.

The double substrate has as a result, windows with high emissivity; about 0.7 (Nian Yang, 2000).

Fig. 3 (by Rissman&Kennan,2014)

In the figure above, from Rissman and Kennan case study on low emissivity windows, we are able to see how = windows work by transmitting most visible light and block ‘heat’ (infrared radiation) in both winter and summer.

A recent publication by Dr Durose, professor at the University of Liverpool, states that, the concept of thin film solar cells became famous in the 70s as an alternative to the use of silicon.

Silicon is an indirect gap semiconductor whereas cadmium telluride and copper indium di-selenide, which are analyzed in the next chapter, are direct, making it ideal to use. The factors which led to the use of thin films on photovoltaics were first of all their non-toxic nature as well as their low cost compared to other methods.

Thin films have many pros which make them lead the solar cell industry, especially the recent years with a major increase from 5 to 15% in the marketplace. (Durose,2012)

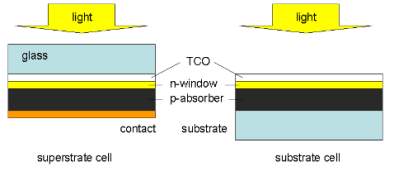

Fig. 4 (by Durose, 2012)

Figure 4 shows the two main designs of thin film solar cells.

On the left, the superstrate cell in which the glass is places on the top, then a layer of transparent conductive oxide (TCO)

Physical properties of oxide thin films are the factor which makes them attractive in the industry of thin films (Kim et al, 2001).Some of those properties are high electrical conductivity, high transparency in the visible spectrum and high reflectivity in the infrared spectrum (Jarzebski et al, 1976). Especially tin oxide thin films are stable at hot weather, resistant to strong acids and bases indoors and have excellent adhesion to many substrates, making them a good choice. (Yusta et al, 1997)

In this paper we report on the electrical, optical and mechanical properties of SnO2 thin films. In addition to the text, appropriate images are provided for better understanding of their applications.

The optical properties of each thin film have an effect on the energy performance of it. In this section, two of the most basic mechanisms of heat transfer are explained, transmittance and reflection, which are then analysed further in the next Chapter.

Transmittance is the rate of radiation that can pass through the material, here window glazing.

We can separate transmittance type by the different spectrum of light that is able pass through e.g. visible spectrum transmittance, ultraviolet transmittance and total solar energy transmittance. (Chaiyapinunt et al, 2004)

Transmission of visible light determines the effectiveness of a type of glass in providing daylight and a clear view through the window. For example, tinted glass has a lower visible transmittance than clear glass. (Franken et al, 2007)

More than half of the sun’s energy is invisible to the eye. Most reaches us as near-infrared with a few percent in the ultraviolet (UV) spectrum. Thus, total solar energy transmittance describes how the glazing responds to a much broader part of the spectrum and is more useful in characterizing the quantity of total solar energy transmitted by the glazing.

With the recent advances in glazing technology, manufacturers can control how glazing materials behave in these different areas of the spectrum. The basic properties of the substrate material (glass or plastic) can be altered, and coatings can be added to the surfaces of the substrates. For example, a window optimized for daylighting and for reducing overall solar heat gains should transmit an adequate amount of light in the visible portion of the spectrum, while excluding unnecessary heat gain from the near-infrared part of the electro-magnetic spectrum.

Glass has the property to reflect either a small or a large amount of light, depending on glazing type of the material, the quality of the glass, weather the glass is coated and of course the angle of the incident radiation of light.(Chowdhury, 2013).Large reflection is similar to mirror-like effect, for example when one sees his reflection on a store’s window.

The reflectivity of different glass types becomes especially obvious when light is not so intense, which is noticeable from outdoors during day-time and from indoors during night-time. (Rakhshani, 1998) The surface on the bright region reacts mirror-like, since the percentage of light passing through it from the dark region is less than the percentage of light being reflected from the bright one.

In some cases i.e. shop windows on a bright day, the intense reflection of light could be unbearable, making the use of anti-reflective coatings on glass essential to reduce the effect.

Special coatings have been discovered since then, which reflect along the whole spectrum. Nevertheless, recently researches took this step forward, discovering coatings that only reflect particular wavelengths of the infrared spectrum.

This created strong basis for the creation of today’s low emissivity coatings, which would be further explained in the next Chapter.

Tin oxide films are electrically conductive, that is the main reason they are used for a variety of applications. (Serin et al, 2017)

A recent publication by the institute of Physics in 2017 proved that there is n-type conduction, the shallow levels are structure defects levels but the deep levels are characteristic of the material. The deep levels were detected by both resistivity and space charge limited current measurements.

An intelligent house is one which is friendly first of all to the environment and secondly to the people living in it. The materials used are environmentally friendly and green energy is being produced for its heating ensuring the sustainability is not jeopardized.

In this section, some of the main applications of thin films in the intelligent house are going to be examined as well as the appropriate semiconductor used for each of them.

The free electrons reflect infrared radiation for wavelengths longer than the plasma wavelength. The effect is similar to that of the silver coating in insulated vacuum bottles (Gordon, 2000). In cold climates, the plasma wavelength should be fairly long, about 2μm, so that most of the solar spectrum is transmitted into heat inside the building. For this purpose, fluorine-doped tin oxide is the most suitable material to use since its plasma wavelength is appropriate. (Gordon, 2000)

In hot climates, a short plasma wavelength ≤1μm is desirable, so that the near-infrared portion of incident sunlight can be reflected out of the building. (ibid)

Fig. 5:(by WindowWorld, 2014)

Figure 5 shows how low-e windows react in summer, left, and winter, right In cold weather, low e takes on a new duty. It lets warm solar rays into the house while blocking the heat from getting out. (see fig. 5)

Low-e glass filters long-wave radiation from the sun. This reduces solar heat gain from the sun in hot weather.As stated by Window World, adding Low-E glass to a standard insulated glass unit can improve the year-round energy performance of your window by 24%

The idea of amorphous silicon was first developed in the ’70s by Stan Ovshinsky, the co-founder of Energy Conversion Devices (ECD) and is a well-known photovoltaic device (Iftiquar et al, 2015).

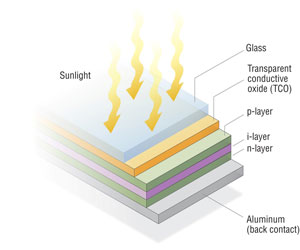

Most common order of layers is n-type, i-type, p-type (Franken et al, 2007). .

Fig.6 (by Maehlum, 2015)

The advantage of the n–i–p type solar cell is that the cell can be fabricated with a pre-determined textured back reflector (BR). Thus a great variation in the passage of light can be obtained in a n–i–p type cell structure (see fig. 6) (Demontis, 2013)

Figure 6 shows the structure of a solar panel with amorphous silicon used.

As reported by the U.S Department of Energy, there are many advantages of using amorphous silicon. To begin with the fact that it requires less silicon (about 1%) than crystalline-slilicon solar cell (indirect-bandgap) since it is a direct-bandgap material. Moreover AS is ‘accepting’ to many different substrates, thus making it easy and in the end inexpensive to produce The deposition happens at temperatures below 300 Their flexibility and their weight could also

On the other hand, there are some disadvantages, starting from the fact that they are believed not to last as long as crystalline-based solar panels which is important in long term. Another important con is that to get equal output as in crystalline-based solar panels one would have to cover a larger surface with AM.

As Dr Heckeroth stated in 2010 amporphous silicon is a flexible thin film that can be used in addition to other materials on roofs. The material then is proved to reach the efficiency of 15% in lab environment and 8.5% in real-world.

As an alternative to amorphous silicon, the idea of copper indium gallium diselenide solar cells was developed in the ’80s. They have even higher efficiencies than AM, reaching 20% in lab environment and 11% in real-world.

A major disadvantage of CIGS is their short life since they are very sensitive to moist environments and is not flexible and lightweight when surrounded by glass thus putting it on the same line with other crystalline solar cells.

Hecheroth states that if the moisture degradation issue can be solved, CIGS, with the highest potential efficiency of any thin film, will probably be the flexible thin film preferable material.

As Dr Gordon states in his article “Criteria for Choosing Transparent Conductors” in 2000, transparent conductors can be deposited on glass to scatter the static charges that can be developed on xerographic copiers, tv tubes and CRT computer screens. For this specific application the only condition is high resistance (≥1kΩ).Tin oxide is the ideal material for these uses as the mechanical and chemical durability would need to be achieved.

After CIGS (section 2.4.3) another material discovered in the ‘90s its efficiency around 16% in the lab environment and 11% in real-world. (Miao et al, 2015)

Switzerland, announced in August 2009 that it has improved the efficiency of flexible CdTe thin-film solar cells to 12.4 percent. This development has the potential to make CdTe the low-cost leader for flexible thin-film applications.

A recent article by Brandon et al(2017), states that organic thin-film transistors (OTFTs) employing a flexible, conductive carbon particle-polymer composite material for the drain-source ohmic contacts are reported herein. They are made from materials that contain carbon. They currently are low efficiency (4-8%) and have a short life expectancy (less than 6 years), so they are far from being a viable product for the building industry or competing in the PV module market.

Thin film industry constantly expands as a result many scientist focus their researches on them

This Chapter centres the discussion on ongoing and recent researches on thin film industry, providing a review for each of them.

Starting with the Perovkite Solar cells, which is a low-cost more durable, classical solar cell replacement, moving on to wearable thin-film oxide transistors.

Then on buildings, a new application for ‘passive cooling’ to thin film use touch screen displays and finally a recent research on how to control oxygen for electronic properties

Transparent Conductive Films are thin films of electrically conductive material. Due to their transparent character, they had become important factor electronic devices nowadays.

Their use do not stop on photovoltaic cells as described on Chapter 2, but also expands on a range of other applications such as touch screen products, LCD screens and OLEDs. (Lee et al, 2016)

Iridium tin oxide is the most common material used to make Transparent Conductive Films in the industry; other materials used are Carbon nanotubes, graphene, silver nano wires which are a huge chapter in nanotechnology nowadays. A key challenge to Transparent Conductive Films market is manufacturing cost as iridium oxide cost increasing and delicateness of the film which had forced scientists to investigate for materials such as carbon nanotubes (ibid).

Perovskite is named after Russian mineralogist Perovskite who first characterized the crystal structure of ABX3-type inorganics. (Green et al, 2014)

Perovskite may be the low-cost solution to solar cells. A perovskite solar cell is a type of solar cell which includes a perovskite structured compound, most commonly a hybrid organic-inorganic lead or tin halide-based material as the light-harvesting active layer. Perovskite materials such as methylammonium lead halides are cheap to produce and simple to manufacture. (Len Calderone,2017)

Perovskite solar cells are a mixture of organic molecules and inorganic elements within a single crystalline structure. Together they capture light and convert it into electricity. They can be manufactured more easily and cheaply than silicon-based solar cells. They can also be bonded to a flexible backing, which means they can be used for many applications where traditional solar panels are not feasible, such as on the roof and fenders of electric automobiles.

In the study, the research team has also proposed a new solar cell manufacturing methodology, entitled the ‘Hot Pressing Method’. This technique bonds two objects together by applying both temperature and pressure, which makes the production of low cost, high efficiency, and stable perovskite solar cells possible. The PSCs developed by the UNIST scored a 22.5% efficiency rating, which compares favorably to the 25% of a traditional solar cell.(Seok, 2017)

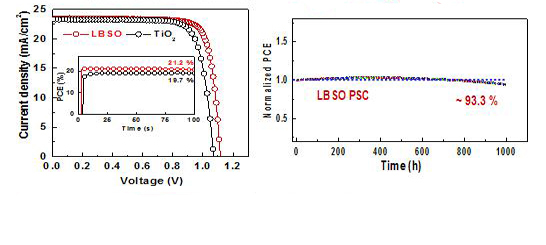

Figure 7 (by Seok, 2017)

Figure 7 above shows the perfomanche of the photoboltaics. Hightlight that after 1000 hours of 100% sun illumination, the efficiency reduction observed in the lab was just 7%.

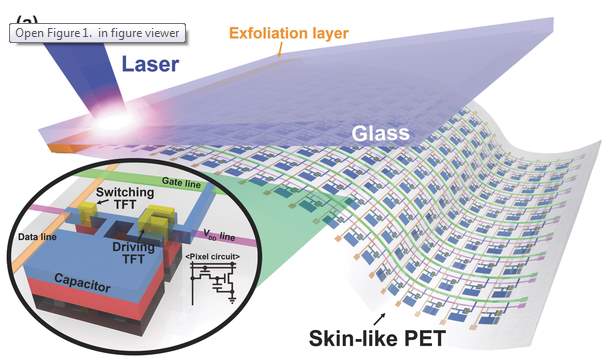

With the advent of the Internet of Things (IoT) era, strong demand has grown for wearable and transparent displays that can be applied to various fields such as augmented reality (AR) and skin-like thin flexible devices (Lee, 2016). However, previous flexible transparent displays have posed real challenges to overcome, which are, among others, poor transparency and low electrical performance. To improve the transparency and performance, past research efforts have tried to use inorganic-based electronics, but the fundamental thermal instabilities of plastic substrates have

Fig.8( by Lee, 2016)

hampered the high temperature process, an essential step necessary for the fabrication of high performance electronic devices.

Research team led by Professors Keon Jae Lee and Sang-Hee Ko Park of the Department of Materials Science and Engineering at the Korea Advanced Institute of Science and Technology (KAIST) has developed ultrathin and transparent oxide thin-film transistors (TFT) for an active-matrix backplane of a flexible display by using the inorganic-based laser lift-off (ILLO) method (Lee et al, 2016).

Figure 8 shows detailed illustrations of a skin-like oxide TFT array for transparent display via the ILLO fabrication process, consisting of a switching TFT, a driving TFT, and a capacitor.

Engineers at the University of Colorado Boulder have developed a thin, artificially structured “metamaterial” that can cool objects without the use of water or energy. The film works to lower the temperature of the surface beneath it through a process known as “passive cooling,” meaning that it vents the object’s heat through thermal radiation while bouncing off any incoming solar energy that may negate those losses. As described in the journal Science the glass-polymer hybrid material couldprovide an “eco-friendly means of supplementary cooling” for thermoelectric power plants, which require colossal amounts of water and electricity to keep their machinery chugging along at optim um temperatures. (Zhai et al, 2017)

Fig.9( by Zhai et al 2017)

By combining the silver with a little bit of aluminum, the U-M researchers found that it was possible to produce exceptionally thin, smooth layers of silver that are resistant to tarnishing. They applied an anti-reflective coating to make one thin metal layer up to 92.4 percent transparent.(Zhang et al, 2017)

Fig.10 (by Xu/Michigan Engineering)

Figure 10 shows professor Guo holding the transparent silver film that could be used in the future for flexible displays

Fig.11 (by Vaal et al, 2016)

Scientists are always looking for unusual behaviors in materials that could form the basis of new technologies. Oxides are a class of materials that has garnered muchrecent interest because they sometimes display such unusual behaviors –flipping

between insulating and conducting states, turning magnetism on and off or even

becoming superconducting: conducting electricity perfectly, without any loss as heat.

We think some of these properties have to do with oxygen vacancies. The structure of an oxide is a repeating crystalline lattice with oxygen atoms peppered throughout, but sometimes there may be voids where an oxygen atom is missing.

The usual way to create oxygen vacancies is by heating the materials and adding or removing oxygen from the environment.(Veal et al,2016)

In this section the intelligent house of the future will be examined, having in mind the materials already discovered and used but also ideas that might sound utopian but Science has already proved that has no limits.

The future intelligent house combines four main factors .First of all, the minimum or zero energy consumption which could be achieved by using the right design but more importantly from the insulation of the house’s ‘body’. An insulated house means less energy loss, thus less energy consumption. Secondly, the minimum energy consumption during the production of the materials used for the construction of it. This factor is directly connected to the thin film industry and how they could be produced using the minimum cost. Moreover, to obtain a more sustainable house, environmentally friendly materials, which are not harmful during their removal, should be used. Materials which are not ‘green’ and their use should be limited are Vinyl polyurethane, extruded polystyrene, asbestos, formaldehyde and lead compound. Lastly, the production of energy should be considered as well. The production should focus as much as possible on renewable sources of energy, as analysed in the sections before, transforming energy from the Sun, the earth and the wind.

A bioclimatic house could save the massive amount of 80% of energy of an old-fashioned house.

Bioclimatic design of a house is the design of indoor and outdoor space based on the climate of the area which they are built in, in order to ensure sustainable thermal and optical solutions. It could be separated in two directions, the study of the environment around the house as well as the choice of the appropriate materials, having in mind their optical and mechanical properties.

First of all the future house uses natural lighting from the sun. Having in mind the maximum transmittance and reflectance properties for window glazing discussed on the section above, the use of transparent thin films is essential.

In bioclimatic design house, electricity and hot-water are provided using renewable sources of energy. For example solar boilers for hot water and solar cells on roofs which collect the energy from the sun to transform directly or indirectly in electricity.

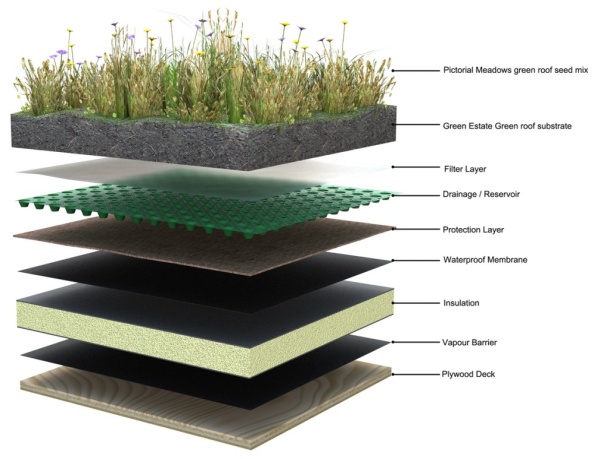

Planted roofs are an idea which has already been widely used and it is recommended for larger cities during summer period when atmosphere becomes ‘heavier’. Green roofs reduce the toxic pollutants of the atmosphere as well as provide cooling to the house, saving up to 30% of energy.

Figure shows a crossection of such a roof.

(By Johnson,2015)

Most of everyday uses of water in our houses could be replaced from recycled water, collecting rain water and saving it in underground tanks for future use, providing the appropriate filtering.

In conclusion, the demand for energy will never stop making it essential for each one of us to start thinking ‘greener’.

Thin films, which this project emphasises on, are constantly improving helping the house of the future becoming more sustainable in various ways.

Its physical, mechanical and optical properties made it stand out between many other materials that offer the same features.

A Specified Procedure for Distress Identification and Assessment for Urban Road Surfaces Based on PCI. (2017). Coatings, 7(5), 65. http://dx.doi.org/10.3390/coatings7050065

Alalouch, C., Saleh, M., & Al-Saadi, S. (2016). Energy-Efficient House in the GCC Region. Procedia – Social And Behavioral Sciences, 216, 736-743. http://dx.doi.org/10.1016/j.sbspro.2015.12.071

Amanullah, F., Pratap, K., & Hari Babu, V. (1998). Compositional analysis and depth profile studies on undoped and doped tin oxide films prepared by spray technique. Materials Science And Engineering: B, 52(2-3), 93-98. http://dx.doi.org/10.1016/s0921-5107(98)00113-5

American Energy Innovation Council Case Study. (2017). Low-emissivity windows (pp. 1-2). Case Studies on the Government’s Role in Energy Technology Innovation.

Bell, M., & Lowe, R. (2000). Energy efficient modernisation of housing: a UK case study. Energy And Buildings, 32(3), 267-280. http://dx.doi.org/10.1016/s0378-7788(00)00053-0

Brandon, E., West, W., & Wesseling, E. (2017). Carbon-based printed contacts for organic thin-film transistors., from

Chaiyapinunt, S., Phueakphongsuriya, B., Mongkornsaksit, K., & Khomporn, N. (2005). Performance rating of glass windows and glass windows with films in aspect of thermal comfort and heat transmission. Energy And Buildings, 37(7), 725-738. http://dx.doi.org/10.1016/j.enbuild.2004.10.008

Chowdhury, F., Blaine, T., & Gougam, A. (2013). Optical Transmission Enhancement of Fluorine Doped Tin Oxide (FTO) on Glass for Thin Film Photovoltaic Applications. Energy Procedia, 42, 660-669. http://dx.doi.org/10.1016/j.egypro.2013.11.068

Demontis, V., Sanna, C., Melskens, J., Santbergen, R., Smets, A., Damiano, A., & Zeman, M. (2013). The role of oxide interlayers in back reflector configurations for amorphous silicon solar cells. Journal Of Applied Physics, 113(6), 064508. http://dx.doi.org/10.1063/1.4790875

Fluorine doped Tin Oxide (FTO) Glass – Substrates | Sigma-Aldrich. (2017). Sigma-Aldrich., from http://www.sigmaaldrich.com/materials-science/material-science-products.html?TablePage=106837645

Franken, R., Stolk, R., Li, H., van der Werf, C., Rath, J., & Schropp, R. (2007). Understanding light trapping by light scattering textured back electrodes in thin film n‐i‐p-type silicon solar cells. Journal Of Applied Physics, 102(1), 014503. http://dx.doi.org/10.1063/1.2751117

Gordon, R. (2000). Criteria for Choosing Transparent Conductors. MRS Bulletin, 25(08), 52-57. http://dx.doi.org/10.1557/mrs2000.151

Granqvist, C. (1990). Window coatings for the future. Thin Solid Films, 193-194, 730-741. http://dx.doi.org/10.1016/0040-6090(90)90225-3

Green, M., Ho-Baillie, A., & Snaith, H. (2014). The emergence of perovskite solar cells. Nature Photonics, 8(7), 506-514. http://dx.doi.org/10.1038/nphoton.2014.134

Hamberg, I., & Granqvist, C. (2017). Evaporated Sn‐doped In2O3 films: Basic optical properties and applications to energy‐efficient windows

Heckeroth, S., & Ogden Publications, I. (2017). The Promise of Thin-Film Solar – Renewable Energy – MOTHER EARTH NEWS. Mother Earth News., from http://www.motherearthnews.com/renewable-energy/solar-power/thin-film-solar-zmaz10fmzraw

Home, Efficiency, & windows, E. (2017). Energy efficient windows. Energy Saving Trust., from http://www.energysavingtrust.org.uk/home-energy-efficiency/windows

Iftiquar, S., Jung, J., Park, H., Cho, J., Shin, C., & Park, J. et al. (2015). Effect of light trapping in an amorphous silicon solar cell. Thin Solid Films, 587, 117-125. http://dx.doi.org/10.1016/j.tsf.2015.02.037

Kern, W., & Vossen, J. (1991). Thin Film Processes (1st ed.). Oxford: Elsevier Science.

Lee, H., Kim, S., Ko, J., Yeom, H., Byun, C., & Lee, S. et al. (2016). Transparent Displays: Skin-Like Oxide Thin-Film Transistors for Transparent Displays (Adv. Funct. Mater. 34/2016). Advanced Functional Materials, 26(34), 6319-6319. http://dx.doi.org/10.1002/adfm.201670222

Low-emissivity Glass. (2017). Pilkington.com., from https://www.pilkington.com/en-gb/uk/householders/types-of-glass/energy-efficient-glass/low-emissivity-glass

Major advance in solar cells made from cheap, easy-to-use perovskite. (2017). Phys.org., from https://phys.org/news/2016-11-major-advance-solar-cells-cheap.html

Nix, W. (1989). Mechanical properties of thin films. Metallurgical Transactions A, 20(11), 2217-2245. http://dx.doi.org/10.1007/bf02666659

Rakhshani, A., Makdisi, Y., & Ramazaniyan, H. (1998). Electronic and optical properties of fluorine-doped tin oxide films. Journal Of Applied Physics, 83(2), 1049-1057. http://dx.doi.org/10.1063/1.366796

Rakhshani, A., Makdisi, Y., & Ramazaniyan, H. (2017). Electronic and optical properties of fluorine-doped tin oxide films., from

Serin, T., Serin, N., Karadeniz, S., Sarı, H., Tuğluoğlu, N., & Pakma, O. (2017). Electrical, structural and optical properties of SnO2 thin films prepared by spray pyrolysis. Retrieved 3 May 2017, from

Shanthi, S., Subramanian, C., & Ramasamy, P. (1999). Preparation and properties of sprayed undoped and fluorine doped tin oxide films. Materials Science And Engineering: B, 57(2), 127-134. http://dx.doi.org/10.1016/s0921-5107(98)00314-6

Shazly, A., Elhady, D., Metwally, H., & Seyam, M. (1998). Electrical properties of thin films. Journal Of Physics: Condensed Matter, 10(26), 5943-5954. http://dx.doi.org/10.1088/0953-8984/10/26/019

Shazly, A., Elhady, D., Metwally, H., & Seyam, M. (1998). Electrical properties of thin films. Journal Of Physics: Condensed Matter, 10(26), 5943-5954. http://dx.doi.org/10.1088/0953-8984/10/26/019

Srinivasa Murty, N., Bhagavat, G., & Jawalekar, S. (1982). Physical properties of tin oxide films deposited by oxidation of SnCl2. Thin Solid Films, 92(4), 347-354. http://dx.doi.org/10.1016/0040-6090(82)90159-6

Thin film facility | University of Oxford Department of Physics. (2017). Www2.physics.ox.ac.uk., from https://www2.physics.ox.ac.uk/enterprise/services-and-specialist-equipment/thin-film-facility

Us, A., & Maehlum, M. (2017). Best Thin Film Solar Panels – Amorphous, Cadmium Telluride or CIGS? – Energy Informative. Energy Informative., from http://energyinformative.org/best-thin-film-solar-panels-amorphous-cadmium-telluride-cigs/

Veal, B., Kim, S., Zapol, P., Iddir, H., Baldo, P., & Eastman, J. (2016). Interfacial control of oxygen vacancy doping and electrical conduction in thin film oxide heterostructures. Nature Communications, 7, 11892. http://dx.doi.org/10.1038/ncomms11892

Windows for High-performance Commercial Buildings. (2017). Commercialwindows.org., from http://www.commercialwindows.org/technologies.php

Windows for High-performance Commercial Buildings. (2017). Commercialwindows.org., from http://www.commercialwindows.org/technologies.php

Wu, S., Yuan, S., Shi, L., Zhao, Y., & Fang, J. (2010). Preparation, characterization and electrical properties of fluorine-doped tin dioxide nanocrystals. Journal Of Colloid And Interface Science, 346(1), 12-16. http://dx.doi.org/10.1016/j.jcis.2010.02.031

Yong Nian Yang, P., & Yadollahi, S. (2000). Low emissivity window films. US.

Yu, M., & Kenny, S. (2015). The energetic impact of small CdxTey clusters on Cadmium Telluride. Thin Solid Films, 584, 41-45. http://dx.doi.org/10.1016/j.tsf.2014.12.019

Zhai, Y., Ma, Y., David, S., Zhao, D., Lou, R., & Tan, G. et al. (2017). Scalable-manufactured randomized glass-polymer hybrid metamaterial for daytime radiative cooling. Science, eaai7899. http://dx.doi.org/10.1126/science.aai7899

You have to be 100% sure of the quality of your product to give a money-back guarantee. This describes us perfectly. Make sure that this guarantee is totally transparent.

Read moreEach paper is composed from scratch, according to your instructions. It is then checked by our plagiarism-detection software. There is no gap where plagiarism could squeeze in.

Read moreThanks to our free revisions, there is no way for you to be unsatisfied. We will work on your paper until you are completely happy with the result.

Read moreYour email is safe, as we store it according to international data protection rules. Your bank details are secure, as we use only reliable payment systems.

Read moreBy sending us your money, you buy the service we provide. Check out our terms and conditions if you prefer business talks to be laid out in official language.

Read more