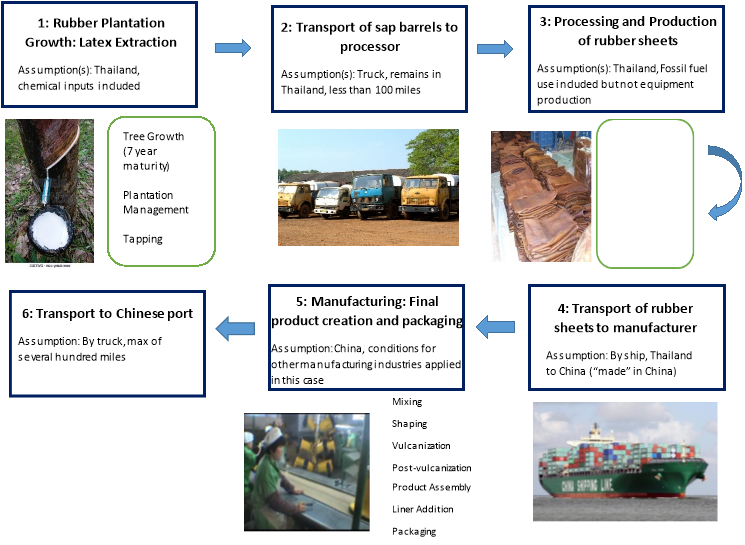

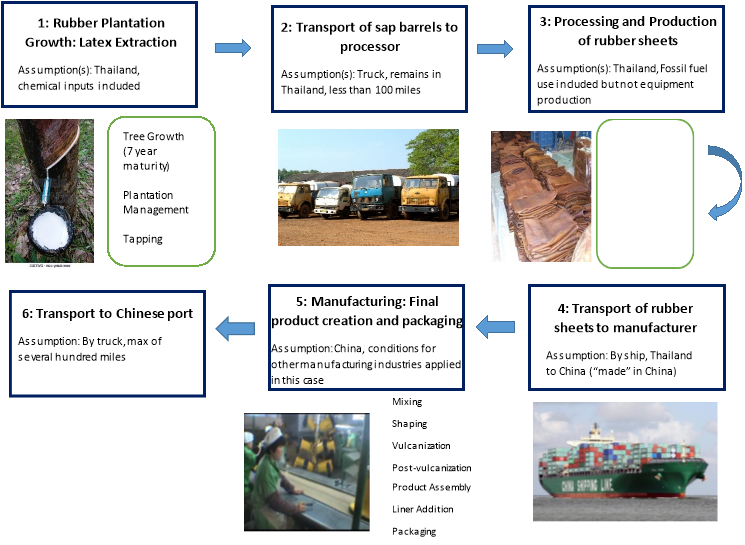

LCA Boundaries and Assumptions:

A hypothetical situation was created to symbolize a likely life cycle for a pair of Joules brand rubber boots. Therefore, Thailand was chosen as a source of natural rubber as one of the world’s largest producers. China was chosen as the Joules company website clearly states their products are “handmade in China”. I contacted the company to see if they could give me information on the location of their manufacturing facility but they could not divulge this. Transportation distances are based on locations of busy forts, shipment through the Suez Canal, and appropriate distances from major ports to smaller retailers within the UK. Another assumption is that these boots are made of 100% natural leather with chemical inputs rather than a mix of synthetic and natural rubber to make the life cycle less complex. Greenhouse gases are considered for processing facilities and transportation but not the footprints of the construction of these facilities and equipment. Also, it is assumed the boots are not recycled or reused and instead, immediately disposed of in a landfill. The working conditions of factory workers in the manufacturing of this product are not specific to the creation of this particular project but the industry overall and facts concerning the presence of rubber in landfills pertains to all forms of rubber (dominated by tires).

Step 1: Rubber plantation growth and latex extraction

- Description of step

- The sap of the rubber tree, or Hevea brasiliensis, known as latex is tapped by diagonally cutting across the tree’s bark and allowing the sap to drain (Peeples, 2016).

- The maturity time for a rubber tree is seven years (Yujie et al., 2012).

- About 300 ml of latex sap can be harvested from one rubber tree each day (Anjitha, 2013).

- Over 90% of the world’s rubber plantations are found in Southeast Asia (Gamaralalage, Sawai, and Nunours, 2016; Rubber Manufacturers Association, n.d.).

- Thailand and Indonesia each produce about one third of annual global rubber production (Ives, 2013).

- “Southeast Asia is only home to 1.5% of historically valuable areas for growth of rubber trees but currently produces 97% of the world’s natural rubber resources” (Ahrends et al., 2015). – planting in sub optimal regions does lead to crop failures

- Environmental Impacts

- Climate

- Topsoil erosion on monoculture plantations ïƒ decreased soil carbon sequestration (Ives, 2013).

- Climate Change likely to lead to unpredictable weather patterns and monsoon periods ïƒ increasing vulnerability of plantations

- Large-scale plantation failures in Southern China were linked to drought and/or unexpectedly cold winters in 2008, 2010, and 2013 (Ahrends et al., 2015).

- Indonesia has faced periods of drought and forest fires that have negatively affected the industry (Suwannakji, 2015).

- Water

- Large amounts of fertilizers and herbicides used on rubber plantations ïƒ eutrophication of local rivers with increase in nitrogen and phosphorus contributions (Gamaralalage, Sawai, and Nunoura, 2016).

- Terrestrial Ecosystems and Animals

- Rubber plantations increasingly planted on steeper hillsides ïƒ monsoon season occurs ïƒ washout of topsoil, altered pH levels of streams, eutrophication (Kaiyoorawong and Yangdee, 2006)

- Asian Development Bank reported that in the Xishuangbanna region of China each hectare of rubber plantation loses an estimated 22.5 tons of soil per year (Ives, 2013).

- Loss of Biodiversity – Many rain forests converted to monoculture plantations (Liu et al., 2006; Li et al., 2007)

- Yunnan Province in China, known for great emergence of rubber industry is also home world’s most northern tropical forests, one fifth of China’s mammals, and one third of its birds (Ives, 2013).

- Loss of forest land cover linked to loss of habitat for species

- In the Yunnan Province of China, plantations are destroying habitats of the Asian elephant and white-checked gibbons (Ives, 2013).

- Loss of protected environmental lands

- From 2005 to 2010, more than 610 square km of protected areas were converted to plantation in Southeast Asia (Ahrends et al., 2015).

- Harm to aquatic environments – Eutrophication in water bodies leads to large-scale algal blooms which die and consume all of the available dissolved oxygen in aquatic environments as they decompose, leading to the collapse of ecosystems and die-off.

- Human Health and Societal Impacts

- Workers on plantations have no knowledge of the market and are controlled by the landowners that employ them. Price fluctuations can have very fast and damaging effects on tapping communities (Ahrends et al., 2015). Long work hours combined with a lack of autonomy lead to less life satisfaction.

- Chinese landowners and companies have begun buying up land on the Malay Peninsula. This means profit from sap no longer stays within local communities (Ahrends et al., 2015).

- Plays into long-term tension in which richer China and Thailand have a tendency to exploite the poorer Laos and Myanmar for resources (Sturgeon, 2013).

- Deforestation and local environmental change are linked to the harm of local ethnic communities, notably in China (Liu et al., 2006).

- Increase in malaria cases on plantations – plantations provide breeding habitats for mosquitoes including latex-collecting cups and water storage containers (Tangena et al., 2016).

- In Thailand and Indonesia, 30-40% of all malaria cases annually are linked to farmers and those associated with the agricultural industry (Bhumiratana et al., 2013).

- Health issues – failing eyesight for tappers who generally work through the night in SEA with limited light, eye and skin irritation and respiratory issues from spraying chemicals without protection, and inadequate rest (Kaiyoorawong and Yangdee, 2006).

Step 2: Transport of sap barrels to processor facility

- Huge tanks on pick-up trucks transport sap to processing facilities not far from plantations (Chaiear, 2010).

- Environmental Impacts

- Climate – considerations for greenhouse gases created from the burning of fossil fuels, notably carbon dioxide

- Air – release of particulate matter, nitrous oxides, etc. that contribute to air pollution

- Human Health and Societal Impacts

- Often the people who own the processing facility also own the plantations as one dominated supply chain in which workers have little decision making power. Trade unions have struggled in some countries because companies will just lay off tons of workers to break them up (Kaiyoorawong and Yangdee, 2006).

- Vehicles used are often old and unsafe from a lack of proper maintenance. A lack of proper infrastructure and safe roadways from plantation to processing facility can increase the risk of fatal car accidents.

Step 3: Processing and production of rubber sheets

- Description of steps:

- Coagulation – collected latex for trees is put into larger tanks and formic acid is added ïƒ latex is allowed to coagulate (takes about 12 hours), product known as coagulum ïƒ coagulum is squeezed through a series of rolls to drive out water, product is soft solid slabs (Anjitha, 2013)

- Smoking – Pressed coagulum is draped over wooden frames and smoked in smokehouses ïƒ several days to dry, result is known as “ribbed smoked sheets” – Can also be done by drying coagulum outside in sun, product is “air dried sheets” and are better grade (Anjitha, 2013)

- Environmental Impacts

- Air

- There is a lot of particulate matter generated particularly in the smoking stage. Particulate matter can affect growth of nearby plantations and cause human respiratory issues (Anjitha, 2013).

- Water

- Water pollution from coagulation process which is very acidic and contains high levels of nitrogen and ammonia (Edirisinghe, 2014).

- Issues associated with eutrophication and additional potential for groundwater contamination can be considered for this step.

- Terrestrial Ecosystems

- Smoking stage requires the burning of a lot of local wood – exacerbates the threat of deforestation and loss of biodiversity

- Human Health and Societal Impacts

- Low hygiene in production facilities – no gloves worn in chemical coagulation treatment (Gamaralalage, Sawai, and Nunoura, 2016). Facilities are likely not cleaned routinely and potential hazards are likely not cleared often.

- Dizziness among workers from daily exposure to ammonia (Gamaralalage, Sawai, and Nunoura, 2016).

- Debate about economic gain vs. environmental detriment

- Some community members in Yunnan Province of China acknowledged environmental harm but said they needed and appreciated the economic gain from the rubber industry (Ives, 2013).

- The average middle class factory worker in Indonesia makes $8.60 per day and $6.70 in Vietnam (Jiaxong and Yangon, 2015). – Very low wages and very dangerous conditions for other careers

- Another study of the garment industry found the hourly wages for factory workers to be; $0.13 per hour in Bangladesh, $0.26 per hour in Vietnam, and $0.44 per hour in China (Powell and Skarbek, 2004) – These have likely risen since 2004 but the proportions still likely remain similar

Step 4: Transport of sheets to Chinese manufacturer

- Ten of the busiest ports in the world are in China with Shanghai being the busiest (Jiaxing and Yangon, 2015). – choice for this exercise

- Environmental Impacts

- Climate – Greenhouse gas emissions need to be considered – However, maritime shipping is the world’s most carbon-efficient form of transporting goods (Helms, 2013).

- Air – “The largest 15 ships in the world emit as much nitrogen oxide and Sulphur oxide as the world’s 760 million cars”. There are few regulations for smoke stack emissions on these ships (Helms, 2013).

- Human Health and Societal Impacts

- Price at port dominated by China who control demand for rubber as the world’s largest manufacturer and user (Kaiyoorawong and Yangdee, 2006).

- Often those working on shipping vessels work long hours and spend many days away from home. This career would make it difficult to have a healthfully functioning family.

Step 5: Manufacturing, final product assembly, and packaging

- Description of steps:

- Compound mixing – Chemicals additive liquid mixture including fillers, vulcanization activators, and accelerators are added to rubber (Anjitha, 2013).

- There are typically between five and twenty additives in most rubbers – one example is carbon black which is used as a reinforcing filler (Forrest, 2015).

- Shaping – consists of 4 main processes

- Extrusion, Calendaring, Coating, Molding

- Consists of very large machines used to clean rubber, chop it into pellets, pressurize it, and form it into new sheets under high pressure – resulting forms of rubber are specific to industry needs and product dimensions (Anjitha, 2013)

- Vulcanization – Process that allows additives to react with rubber to give it its stiffer, stronger, heat and cold tolerant characteristics – subject to very high temperatures (Anjitha, 2013)

- Liners for boots are spun from polyester yarn – A machine spins the form (Guney, 2013)

- Liner and inner rubber form are formed – outer rubber pieces are applied (Nicholson, 2011) – several steps and product checks here

- Company labels applied (Guney, 2013)

- Packaging with cardboard outer box and paper interior packaging (Guney, 2013)

- “Handmade” likely means exterior rubber and sole placement is done by hand but machines still provide greater efficiency at each step (Nicholson, 2013)

- Environmental Impacts

- Air

- There is a terrible odor associated with rubber processing associated with ammonia and other, potentially toxic, compounds (Ives, 2013).

- Over 30 different potentially harmful chemicals have been found in rubber processing fumes – include highly volatile hydrocarbons, amines, aldehydes, aerosols, etc. (Forrest, 2015).

- Although the Joules company claims to be handmade, it is almost guaranteed that many steps of the production process are partially mechanized. This means all of the machines are powered by fossil fuels that emit greenhouse gases when burned (Also linked to climate)

- Climate

- Large amount of VOCs created in aforementioned manufacturing processes (Anjitha, 2013).

- Ozone depleting substances have been found in coatings and adhesives used in some factories (Anjitha, 2013).

- Other gases produced from the rubber industry include carbon dioxide, nitrous oxides, and carbon monoxide (Akrill et al., 2002).

- Water

- Industry produces effluents that are not properly treated in many situations and released directly into surrounding environments ïƒ groundwater pollution (Hamid et al., 2016) – potential impacts to aquatic environments and collapse of communities similar to those mentioned above

- Ex: Sri Lanka – small operations on the island contribute a majority of rubber – do not have access to adequate water treatment facilities ïƒ disgusting odor of water linked to effluent discharge, decreased water quality (Gamaralalage, Sawai, and Nunoura, 2016).

- Lead has also been found in dangerous amounts in effluent discharge (Akrill et al., 2002).

- Human Health and Societal Impacts

- The machines and knives used in extrusion pose occupational hazards for workers whose hands can get trapped when machines get clogged (Hamid et al., 2016).

- Very loud machines throughout the final processing stages can cause ear drum damage for workers who are not given proper means for ear protection (Akrill et al., 2016).

- Many negative health effects found: (Anjitha, 2013; Akrill et al., 2002; Ke and Shunzhang, 2002; Chaiear, 2010)

- Deaths from bladder, stomach, lung, and other cancer in rubber industry- companies claim it is difficult to link to specific chemicals or worker roles, but black carbon, for example, known to be carcinogenic

- Benzene exposure linked specifically to leukemia in electronics manufacturers – benzene also used in rubber manufacturing (Blanding and White, 2015)

- Skin rashes and other irritation

- Adverse respiratory effects including chest tightness, shortness of breath, chronic cough, etc

- Birth defects were also experienced in women pregnant during their work in the rubber industry.

- The negative health effects of the rubber industry were first studied back in the 1950s (Uchida et al., 1993).

- The issues are still not being effectively dealt with. The Chinese government often underreports workplace-related accidents and illnesses. Companies attempt to use whatever loopholes available to avoid paying workers’ compensation and one-time settlements are commonly pushed. The Chinese healthcare system is also inefficient and workers are caught in a complex web (Blanding and White, 2015).

- Work place accidents are common due to the mishandling of highly volatile and flammable components ïƒ freqent explosions and associated health impacts and fatalities (Hamid et al., 2016; Chaiear, 2010).

- Total vision loss for some workers was reported in a massive rubber production zone. The most likely cause was black carbon exposure (Hamid et al., 2016).

- Increasing suicide rates in China’s manufacturing industry – linked to long work hours and repetitive nature of work (Smyth et al., 2013).

- One study for hours worked for migrant workers in China showed 40% worked 40-60 hours per week, 25% working 70 hours per week and 7% working more than 70 hours. The mean was 55.5 hours per week (Feng et al., 2002).

- Many migrant workers are also not part of the workers’ compensation system in China allowing companies to exploit them and not be held responsible at health for paying medical bills, lost wages, etc. (Blanding and White, 2015).

- Rationale for products not being handmade in the UK – China’s factories are far cheaper than in other rich nations. Many workers get paid right at the minimum wage which is about one quarter of that in the US. Many companies are moving farther inland in China for even cheaper wages in previously poor rural areas (Jiaxing and Yangon, 2015).

- Also, studies have found multinational companies offer higher wages and a better standard of living than domestic subcontractors would offer. Therefore, many view the system as important for a better lifestyle (Powell and Skarbek, 2004).

Step 6: Transport of final product to port

- Environmental Impacts – similar to Step 2 but the distances traveled are likely longer putting more stress on people are work many long hours away from home

Step 7: Shipment of product to the UK

- Environmental Impacts – similar to step 4, assuming freight is coming through the Port of Felixstowe, the UK’s largest port (World Shipping council, 2017)

Step 8: Transport to UK seller facility

- Environmental Impacts – similar to step 2 and 6

Step 9: Product use

- Environmental Impacts – not very relevant when in the use of the consumer other than considering that people needed to drive to the store or have products delivered from online by truck – the previous greenhouse gas emissions and air polluters are also included here

(I chose not to include treatments and additional waterproofing coatings sometimes added, but they can contain chemicals potentially leading to air and water pollution.)

- Human Health and Societal Impacts

- Company marketing makes one think that the product is handmade by a UK company, but upon further examination it is obvious the product was made in China. After contacting the company, I know it is very difficult to know the origins of any of the natural resources or where the product is actually manufactured. Also, the marketing of Joules attempts to market to rural communities in terms or durability and will show farms in adds, but also market to more “posh” urban consumers with bright colors, patterns, and bows in designs.

- Joules has fewer products marketed on their site than many other brands and so want to appear as a timeless brand. However, they still advertise new lines and products differ by year. This is still breeding a consumption culture of needing the new and different design rather than keeping the boots for an extended lifetime.

Step 10: Disposal

- Description of step

- Although rubber boots could be reused and can have a potentially long lifetime with one consumer, we are skipping directly to disposal in a landfill.

- There are over 200 million waste tires in the US alone taken to landfills each year. Rubber only makes up less than 8% of total US landfill composition (Clark, 2013).

- There is also waste from all of the other production processes that is also likely transported to landfills or not disposed of the most environmentally conscious way. For example, the cardboard and paper packaging could be recycled, but for this case, I will assume the consumer fails to do so. Undesirable rubber sheets due to insect accumulation or products made incorrectly likely go to landfills as well, piling up as workplace hazards in factories before disposal. However, this is the consumer usually does not consider.

- Environmental Impacts

- Water

- Natural rubber would be biodegradable before treating but additives and layers apply make this unlikely in landfills. Chemical additives can leach out of improperly sealed landfills ïƒ water pollution (Clark, 2013)

- Climate

- Natural rubber in landfills, if able to biodegrade will still contribute to methane creation within landfills.

- Human Health and Societal Impacts

- Countries like the UK with very limited land area need to make tough decisions as a society about how to ethically and efficiently deal with issues of waste. Therefore, in this way each consumer is affected.

References

Ahrends, A., Hollingsworth, P. M., Ziegler, A. D., Fox, J. M., Chen, H., Su, Y., and Xu, J. (2015) Current trends of rubber plantation expansion may threaten biodiversity and livelihoods. Global Environmental Change, 34, 48-58. doi:10.1016/j.gloenvcha.2015.06.002.

Akrill, P., Cocker, J. and Dixon, S. (2002) Occupational exposure in the rubber manufacturing industry. IARC, 134: 265-269.

Anjitha, G. (2013) Rubber and environment. Sri Lanka Insitute of Information, Technology. Academia.edu. from http://www.academia.edu/6391326/Rubber_and_environment [12.2.17]

Bhumiratana, A., Sorosjinda-Nunthawarasilp, P., Kaewwaen, W., Maneekan, P., and Pimnon, S. (2013) Malaria-associated rubber plantations in Thailand. Travel Medicine and Infectious Disease, 11(1), 37-50. doi:http://dx.doi.org.ezproxy1.allegheny.edu:2048/10.1016/j.tmaid.2012.11.002.

Blanding, M., and White, H. (2015) How China is screwing over its poisoned factory workers. Wired. https://www.wired.com/2015/04/inside-chinese-factories/#slide-3 [5.3.17].

Chaiear, N. (2010) Update on health and safety in the rubber industries. GB: Ismithers Rapra.

Clark, T. (2013) Advancements in rubber disposal: Biodegradation and the environment. ENSO Plastics, LLC. International Latex Conference 2013. ://www.linkedin.com/pulse/20140501222120-11496812-advancements-in-rubber-disposal-biodegradation-and-the-environment [27.2.17]

Edirisinghe, J. C. (2014) Taxing the pollution: A case for reducing the environmental impacts of rubber production in Sri Lanka. Journal of South Asian Development, 9(1), 71-90. doi:10.1177/0973174113520585.

Forrest, M. (2015) The composition and nature of vulcanisation fumes in the rubber industry – A technical review. Progress in Rubber, Plastics and Recycling Technology, 31(4), 219-264.

Gamaralalage, D., Sawai, O., and Nunoura, T. (2016) Effectiveness of available wastewater treatment facilities in rubber production industries in sri lanka.”International Journal of Environmental Science and Development, 7(12), 940-945. doi:http://dx.doi.org.ezproxy1.allegheny.edu:2048/10.18178/ijesd.2016.7.12.908.

Guney, I. (2013) How it’s made: rubber boots. Discovery Channel. Youtube.com. https://www.youtube.com/watch?v=BuSWAMxdcHg [25.2.17].

Hamid, A., Saeed, I., Akhtar, S., and Ahmad, S. R. (2016) Environmental profile of a rubber industry. Nature Environment and Pollution Technology, 15(3), 957-961.

Helms, J. (2013) World’s 15 biggest ships create more pollution than all the cars in the world. Industry Tap News. http://www.industrytap.com/worlds-15-biggest-ships-create-more-pollution-than-all-the-cars-in-the-world/8182 [28.2.17].

Ives, M. (2013) The rise of rubber takes toll on forests of southwest china. Yale Environment 360 (E360). http://e360.yale.edu/features/the_rise_of_rubber_takes_toll_on_forests_of_southwest_china [12.2.17].

Jiaxing and Yangon. (2015) The future of factory Asia: A tightening grip. The Economist. http://www.economist.com/news/briefing/21646180-rising-chinese-wages-will-only-strengthen-asias-hold-manufacturing-tightening-grip [26.2.17].

Kaiyoorawong, S. and Yangdee, B. (2006) Rights of rubber farmers in Thailand under free trade. Project for Ecological Awareness Building. http://wrm.org.uy/oldsite/countries/Thailand/Rights_of_rubber_farmers_in_Thailand.pdf [27.2.17]

Ke, L., and Shunzhang, Y. (2002) Mortality in a Chinese rubber factory: A prospective cohort study. Journal of Occupational Health, 44(2), 76-82. doi:10.1539/joh.44.76.

Li, H., Aide, T. M., Ma, Y., Liu, W., & Cao, M. (2007) Demand for rubber is causing the loss of high diversity rain forest in SW China. Biodiversity and Conservation, 16(6), 1731-1745. doi:10.1007/s10531-006-9052-7.

Liu, W., Hu, H., Ma, Y., & Li, H. (2006). Environmental and socioeconomic impacts of increasing rubber plantations in Menglun Township, southwest China. Mountain Research and Development, 26(3), 245-248,250-253.

Nicholson, J. (2011) Boot assembly operations. Youtube.com. https://www.youtube.com/watch?v=H0nDuWIp3K0 [25.2.17].

Peeples, L. (2016) The origin of rubber boots. Scientific American. The Sciences Online. https://www.scientificamerican.com/article/origin-rubber-boots-amazonian-indians-goodyear/ [25.2.17].

Powell, B. and Skarbek, D. (2004) Sweatshops and third world living standards: are the jobs worth the sweat? The Independent Institute. http://www.independent.org/publications/working_papers/article.asp?id=1369 [5.3.17].

Rubber Manufacturers Association (RMA). (n.d.). Rubber faqs. RMA online. https://rma.org/about-rma/rubber-faqs/ [12.2.17].

Smyth, R., Qian, X., Nielsen, I., and Kaempfer, I. (2013) Working hours in supply chain Chinese and Thai factories: Evidence from the fair labor association’s ‘Soccer project’. British Journal of Industrial Relations, 51(2), 382-408. doi:10.1111/j.1467-8543.2011.00881.x.

Sturgeon, J. C. (2013) Cross-border rubber cultivation between China and Laos: Regionalization by Akha and Tai rubber farmers: Cross-border rubber cultivation. Singapore Journal of Tropical Geography, 34(1), 70-85. doi:10.1111/sjtg.12014.

Suwannakij, S. (2015) Too much rubber, too few tires leaves tappers in a sticky place. Bloomberg Markets. https://www.bloomberg.com/news/articles/2015-12-29/too-much-rubber-too-few-tires-leaves-tappers-in-a-sticky-place [26.2.17].

Tangena, J. A., Thammavong, P., Wilson, A. L., Brey, P. T., and Lindsay, S. W. (2016) Risk and control of mosquito-borne diseases in southeast Asian rubber plantations. Trends in Parasitology, 32(5), 402-415. doi:10.1016/j.pt.2016.01.009.

Uchida, Y., Nakatsuka, H., Ukai, H., Watanabe, T., Liu, Y. T., Huang, M. Y., and Ikeda, M. (1993) Symptoms and signs in workers exposed predominantly to xylenes. International Archives of Occupational and Environmental Health, 64(8), 597-605.

World Shipping Council. (2017) About the industry: top 50 world container ports. World Shipping Council. http://www.worldshipping.org/about-the-industry/global-trade/top-50-world-container-ports [28.2.17].

Yujie, Z., Jusheng, J., Zongbo, P., Qunhui, W., and Daiqun, X. (2012) Ecosystem management in the natural rubber industry. Journal of Resources and Ecology, 3(3), 230-235. doi:10.5814/j.issn.1674-764x.2012.03.005.