Table of Contents

4.1 Background of this Project

4.3. Objective of this Project

4.4. Historical of Diesel Engine

4.4.1. How does diesel engine work

5.1. Advantage of using Compress Natural Gas

5.1.3. Reduce Maintenance Cost

6.1. Thermodynamic Principle (Air-Standard Cycles)

6.2.3. Mean Effective Pressure

7.2. Background of Compressed Natural Gas

7.3. How Different Shape of Compressed Natural Gas affects the Geometry Efficient

7.4. The Method to Refuel Compress Natural at Home

7.5. How does Compressed Natural Gas Work

7.5.1. Compressed Natural Gas Fuel Delivery System

7.5.2. Advanced CNG Technology

7.5.3. Work Principle of Dual Fuel

7.5.4. Advantage of Using Dual Fuel

8. EEXPERIMENT METHOD AND PROCDURE

9.5.1. Data Analysis of Diesel Fuel Experiment

9.5.2. Data Analysis of Mix Fuel Experiment

9.5.3. Data Analysis of Biofuel Test Experiment

9.5.4. Data Analysis of Emission Test Experiment

10. COMPARISION BETWEEN COMPRESSED NATURAL GAS, BIOFUEL AND DIESEL FUEL

10.10. Specific Fuel Consumption

11.5. Possible Error Have Made During Experiments and Suggest Methods Reduce the Error

11.6. Recommend how to Increase the Efficiency by using Compressed Natural Gas

12.5. Compressed Natural Gas is the Best Choice

12.6. How does Compressed Natural Gas Affect Our Daily Life

12.7. Prospect and Estimate Compressed Natural Gas in the Future

14.6. Pictures of latest Compressed Natural Gas vehicles design

The reason to choose this topic because of I have considered 3 different problem by using diesel fuel and gasoline fuel. The first problem is about the environment problem. The second problem is fuel prices and the last problem is whether the fuels is sustainability. Therefore, it motivate me to investigate which alternative fuels more eco-friendly to the environment. As a result, I have chosen compressed natural gas to be my research topic. Moreover, there had some of scientists said that compressed natural gas and electric are going to use in vehicles in the future.

List of the Abbreviation

NOx Nitrogen Oxides

CO Carbon Monoxide

CO2 Carbon Dioxide

O2 Oxygen

T.H.C. Tetrahydrocannabinol

CNG Compressed Natural Gas

FWO Food Waste Oil

CH4 Methane

Cl Combustion Ignition

NG Natural Gas

ECM Electronic Control Module

CNG-DI Compressed Natural Gas with Direct Injection System

CNG-BI Compressed Natural Gas with Biofuel Injection System

Gasoline-PI Gasoline Port Injection System

SFC Specific Fuel Consumption

HC Hydrogen Carbon

In recent 10 years, technology is developed tremendous speed. Especially in automotive industries. In the previous year, most of the car uses diesel fuel and biofuel to be car fuel. However, Jonathan (2016) quote the government’s climate advisers said around 500,000 diesel trucks must progress stop to use and eliminate because these Lorries emit 19 million tons of CO2 in every year. Mike (2016) comments that if the UK use an electric and gas-powered vehicle, the emissions must cut from 500 million tons per year to 120 million tons by 2050 and to 10 million to 20 million tons by 2100. Therefore, natural gas has been developed to be one of the alternative fuel. Most of the fuel industries want to develop compressed natural gas because of compressed natural gas more efficiency than diesel fuel and biofuel. Also, the price by using CNG cheaper than other fuels. The most important thing is CNG eco-friendly to the environment.

The aim of this project is to investigate the feasibility of using compressed natural gas as an alternative fuel in the diesel engine. The project is divided into four sections, including background research, efficiency comparison, emission analysis, analysis of the alternative fuels. The current situations of the three alternative fuels are investigated in background research. The engine power, fuel consumption and mean effective pressure will be investigating in efficiency comparison section. The improvement and suggestion have provided after finished the experiment and research by using diesel fuel, bio-fuel and compress natural gas.

Experiment analysis by using data and evaluate the emission test. In experiment analysis, the experiment results have been generated after the test. Such as analysis the result of bio-fuel and diesel fuel.

Efficiency comparison. The work has been done by using the data which came from the experiment. The comparison includes the theoretical and experimental result of biofuel, diesel fuel, and compressed natural gas.

Find some case study about compress natural gas vehicles. The work has searched and analysis how compressed natural gas applies to various vehicles in different countries.

Compare fuel efficiency/ fuel consumption. After finishing experiments, the work has been done by using the experimental data to compare which of the alternative fuel (as biofuel, diesel, and compressed natural gas) is more efficiency and lower cost due to higher efficiency.

Identify of Diesel cycle, Otto cycle and Dual cycle based on the experimental result.

The first diesel engine (also known as a compression-ignition or CI engine), who built it by Rudolf Diesel in 1897s. Diesel Engine has two versions, which are two-stroke and the four-stroke. The difference between a two-stroke and four-stroke engine is two-stroke engine has a high specific power. Also, two engines has a greatly reduced number of moving parts, more compact, much lighter than four strokes, the cooling system is less than four-stroke, have high power-to-weight and power-to-volume ratios and create more exhaust emissions than four-stroke engines. Nowadays, most of the diesel engine using diesel to be fuel. The concept of the diesel engine uses compressed air to the degree, so that the temperature rise. It’s based on the theory of adiabatic compression. Diesel engine mostly applies to larger cars. Such as truck, bus, ship, etc.

Firstly, diesel fuel is injected into the fuel injection system into the engine cylinder Secondly, the liquid fuel is injected at high velocity as one or more jets through small orifices or nozzles in the injector tip, atomizer into small drops and penetrates into the combustion chamber. Thirdly, the combustion process is controlled and governed by mixing and combustion takes place where the fuel meets oxygen (non-premixed combustion). There have 2 types of diesel combustion system. The first type is direct injection system and the second type is indirect injection system. In direct injection system, the single combustion chamber into which fuel is injected directly. In direct injection system, the combustion chamber is divided into two regions and fuel is injected into pre-chamber. Although the simple construction and small surface area of the combustion chamber, it reduces heat loss and fuel consumption. In addition, the surface area of the combustion chamber has lower volumetric rate, it decreases the cooling lost. Furthermore, the probability of combustion chamber deformation decrease due to uncomplicated design.

In indirect combustion system, small high-speed engines require faster mixing. Therefore, vigorous charge motion is needed. The pros by using indirect injection combustion system are injection pressure lower than others (approximately 80~150 bar) so that it decreases malfunction of the fuel system and have durability. Besides, air-fuel mixture better than DI system.

Biofuel is one of the renewable and sustainable resources. Biofuel produced by plant biomass, vegetable oils, treated municipal and industrial waste. Normally, the application by using biofuel is for vehicle. It used as a diesel and compressed natural gas fuel additive to reduce the practical. Such as carbon monoxide (CO), nitrogen oxides (NOx), carbon dioxide (CO2) and oxygen (O2), hydrogen carbon (HC) from diesel-powered and compressed natural gas powered vehicles. Also, biofuel is one of the most popular fuel in the world. The application by using biofuel in passage car, bus, truck and Fast Attack Craft, JAS-39 Gripen fighter. Megan (2017) mention that NASA confirm that .WORLDWATCH INSTITUDE (2016) stated that in 2010, the worldwide production of biofuel reached 105 billion liters and up 17% from 2009.

The U.S Department of Energy (2014) stated that using compressed natural gas can save around $0.90 (£0.72) per miles in fuel cost. The reason to save fuel cost because of compressed natural gas is easier to burn than biofuel and diesel fuel (C12H23) due to CNG comprises lower hydrocarbon. In comparison with biofuel and diesel fuel, CNG needs less energy to break the hydrocarbon bond because of low boiling point. Therefore, it needs CNG to produce higher energy and efficiency than biofuel and diesel fuel so that it reduces fuel cost.

Compare with diesel fuel and biofuel, compressed natural gas more eco-friendly to nature. OECD (2010) illustrate the figure of emissions, they said that using CNG can reduce 25% of CO2 (on average) emit. According to the European Natural Gas Vehicles Association (2009), they point out that using Dual-Fuel in Heavy-Duty Vehicle (HDVs) have approximately 20% CO2 advantage compared to normal diesel vehicles. Compare with diesel fuel, using spark ignited in NGVs under HDVs can emit around 13% less CO2 than diesel fuel because of efficiency loss in diesel vehicle so that increase amount if equipment for emission as NOx and particulate matter, ENGVA claims. CNC-ONE (2016) said that CNG is the cleanest fuel under transportation market. Furthermore, they mention CNG produce around 20-30% greenhouse gas emission.

According to CNG-ONE (2016), the reason for using CNG reduce maintained cost because CNG doesn’t consist lead. Lead is the toxic and harmful element, which affect the durability of spark plug and environment. Increase the spark plug life using CNG is the best choice due to CNG is no fouling. Although CNG does not contain pollute crankcase oil, the gap between oil changes and tune-ups can extend. Furthermore, pipes and mufflers (install in exhaust system) can be use longer due to CNG cannot react with metals.

Argonne (2010) cite that although compressed natural gas has a high-octane rating (around 130), the power increase in spark-ignition engines. Moreover, CNG-ONE point out high octane rating affect the experience of less engine knock, no vapor locking and no any engine lag under cold or hot weather condition. Engine Knock affect the performance of the engine and decrease the spark plug, piston, cylinder the durability.

Compare with diesel tanks, CNG fuel storage tanks are stronger and safer because CNG tanks normally make by reinforced fibers as well as glass fibers, Kevlar (aramid) and carbon fibers (Dr. John in 1995). In recent years, some newer tanks are made by polymers and composites (Christine & Scott Gable, 2016). These new materials are stronger than steel. Although composite and polymer are heat resistant material, it cannot auto-ignite or catch fire under the standard temperature.

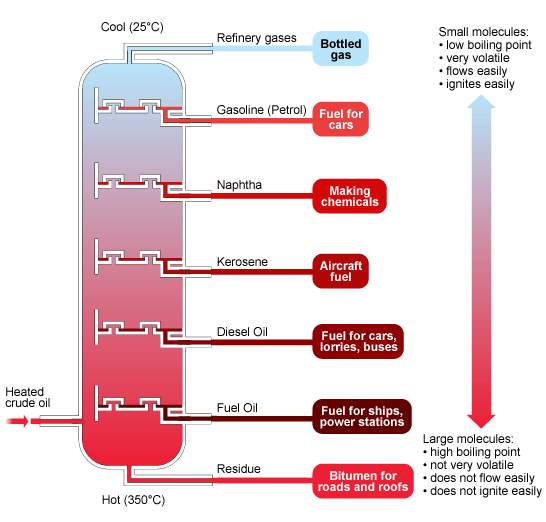

Fractional Distillation is the process which based on boiling point difference and separates a mixture into several different parts. The crude oil has been used during Fractional Distillation process. In this process, the crude oil is drying up and then based on the concentration and temperature differences allowed its vapours in the fractionating column. Although different column represents the various temperature and concentration, it includes hydrocarbon molecules and similar number carbon atoms. The molecule formula to represent various name of fractions, which is CnH2n+2 (n is the number of carbon). For example, if only 1 carbon. C1H2(1) +2 is CH4. We called it methane. The different boiling point, the concentration of hydrocarbon molecules used it in the different way. Picture 1.1 illustrate different application of various hydrocarbon molecules.

(Diagram 1.1 The application of different hydrocarbon molecules http://www.bbc.co.uk/schools/gcsebitesize/science/aqa_pre_2011/rocks/fuelsrev3.shtml)

According to Picture 1.1, the picture illustrates that the difference between large molecules (at the bottom) and small molecules (at the top). The properties of small molecules are the low boiling point, very volatile, flows easily, ignites easily. The properties of large molecules are not very volatile, does not flow easily, and does not ignite easily. The trend of large and small molecules difference also can represent by the table (table 1.2)

| Fraction |

You have to be 100% sure of the quality of your product to give a money-back guarantee. This describes us perfectly. Make sure that this guarantee is totally transparent.

Read moreEach paper is composed from scratch, according to your instructions. It is then checked by our plagiarism-detection software. There is no gap where plagiarism could squeeze in.

Read moreThanks to our free revisions, there is no way for you to be unsatisfied. We will work on your paper until you are completely happy with the result.

Read moreYour email is safe, as we store it according to international data protection rules. Your bank details are secure, as we use only reliable payment systems.

Read moreBy sending us your money, you buy the service we provide. Check out our terms and conditions if you prefer business talks to be laid out in official language.

Read more